Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

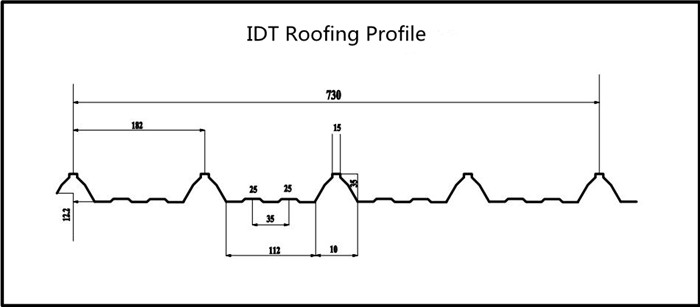

Africa popular Industrial Deep Trough IDT Roofing and cladding roll forming machine

This is excellent for residential, industrial, commercial and agricultural applications. IDT guarantees to add durability and style to your building.

Water tight side lap – the panels which interlock to create the attractive look also provide for the water tight seal.

They have a deep anti siphon groove which protects against leakage.

Superior strength – the major ribs are 180mm apart and approximately 38mm high with 2 minor ribs in between. These minor ribs along with the superior thickness of our materials make this panel extremely strong. This not only adds considerable durability to your building but also prevents rippling during the construction process.

Production length: This is usually based on customer’s wood work specifications

Working flow:

Decoiler------feeding------roll forming------cut to length-----output table

Main technical parameter:

1. DECOILER

(1) Max. Width: 1250 mm

(2) Inner Diameter: Φ450 – Φ550 mm

(3) Out Diameter: 1500 mm

(4) Max. Loading Capacity: 5000 kgs

2. ROLL FORMING MACHINE

(1) Material Thickness: 0.2-0.8mm PPGI and GI

(2) NO. of roller Stations: 16groups

(3) Material for Rollers: high grade 45# steel polished and coated

with chrome HRC55-60°

(4) Material for shaft: high grade 45# steel polished and coated

with chrome HRC55-60°

(5) Diameter of shaft: 70mm

(6) Frame panel thickness: 20mm

(7) Bottom frame: 350 H-section steel

(8) Motor Power: 3kw

(9)Driven type: 1"Chain

(10)Speed:8-12m/min

3. CUT-OFF DEVICE

(1)Material for Cut-Off Modular:Cr12 steel after treatment

(2)Hardness for Heat Treatment:HRC55 – 60°

(3)Cut-Off Type: Hydraulic, Automatic Cut-Off

(4) Motor for Hydraulic Stand: 3 kW

4. PLC CONTROL BOX

(1) Type: PLC Frequency Control System with touch screen

(2) PLC Brand:Delta

(3) Encoder Brand: Omron

(4)Length Error: ±2mm

(5)Voltage: 380v/50HZ, 3Phase

| Working conditions | |

| 1.working size | 22m x 2m x 4m |

| 2.Power supply | 6kw |

| 3.Frequency | 50-60HZ |

| 4.Wires/cables | 4-6mm²(length according to workshop) |

| 5. Labor cost | 2 workers |

| 6. Tools | Spanners and screwdriver |

| 7.Lift device | 3-5t forklift or crane |

Installation and Training:

① If buyers visit our factory and check the machine, we will teach

you how to install and use the machine, and also train your

workers/technician face to face.

② Without visiting, we will send you user manual and video to teach

you to install and operate.

③If buyer needs our technician to go to your local factory,please

arrange round trip tickets, food and hotel and everyday salary

USD100, visa cost and necessary things.