Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

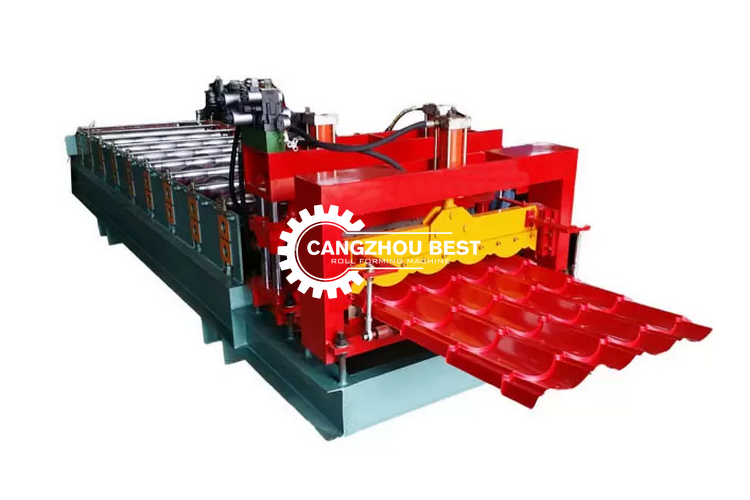

Professional Roof Tile Roll Forming Machine PLC Control For Roofing Buildings

Quick Detail:

Application:

Most of time, a glazed tile roll forming machine has more roll forming stations and rolling tools than a regular roof panel roll forming machine does, and an extra hydraulic pressing equipment also contributes a higher price compared to a regular metal roofing sheet roll forming machine.

This semi-round shape profile is popular in Philippines, Sri Lanka with heavy strength pressures

Machine list:

Description/Technical Parameter details of complete line:

Hydraulic system to expand coil inner hole, Pump motor: 3KW

Coil Inner-diameter= 510±30mm

Load Capacity: Max. 5 Tons

Coil Width Max. 1250mm

Taper wedge expand type

Driving motor to turn the coil, 3KW

Smart cut control

To cut off the end of the final piece of sheet only

Working thickness: max. 0.6mm

| Suitable roll forming material | Color steel sheet or galvanized steel sheet, soft material |

| Thickness | 0.4mm*0.6mm |

| Coil input width | 1219mm |

| Carriage Frame design | Wall-plate-frame-design, plate thickness 18mm |

| Roll forming stages | 16 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75mm |

| Main motor power | 7.5Kw |

| Production speed | 3-4m/min, 7-8m/min as request |

| Stair depth | 20mm or as request |

| Stair distance | 350mm or as per order |

| Hydraulic group | 7.5Kw with professional fans cooling system |

| Material of cutting blade | Cr12, hear treatment |

| Electric Voltage Standard | 415V/50Hz/3Ph or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as per customer’s requirements |

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand Inverter, Omron encoder

Control the quantity, drawing length (250-350mm) & cutting length (min.800mm) automatically.

Cut-to-length tolerance≤±1mm

Control Voltage 24V