Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

General information for the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

Products made by this machine is easy to install, used together with different colors can make it appear dye-in-the-wood individual character. Width of 75, 100, 150, 200, and 300 C-shaped keel can be assembled arbitrarily, and they are connected tightly. They can be fixed on the device which is specially used for keels, they can tear down individually.Material for this machine is galvanized steel plate, snowflake plate and colored steel plate

Detailed components introduction for Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

1.Manual Decoiler of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

1):coil inner diameter: 450-550mm

2):coil max width: 1250mm

3):max carrying capacity: 5000kg

Usage:It is used to support the steel coil and uncoil it in a

turnable way.

Passive uncoil pulled by roll forming system

2.Coil feeding part of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

Usage:Put the raw material(steel plate) through the beach to

manufacture and process,

it can guarantee that the products are neat, parallel and

everything is uniformity.

Please refer to the equipment regulation to know the function of

locate angle iron.

3.Main roll forming machine part of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

1).roller material: 45# steel with hot treatment at 52-68 degrees,

hot chormed on the surface to make sure its hardness.

shaft material: solid shaft(not hollow style), around 70kg/pc, to

make sure the strength of it.and final profile shape are perfect in

this way.

shaft diameter: normally is 72mm.

2).power: normally 7kw in total

3).transmission model: gear and chain

4).controlling model: PLC controlling system, fully automatic.

5).Forming speed: 0-17m/min

Usage: In order to keep the product shape and precision, adopts

welded sheet structure, motor

reducer drive, chain transmission,roller was chromed which can keep

the molding plate surface

smooth and not easy to be marked when it is working

4.Automatic cuttting system of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

1).Material: blade, puncher and mold material: Cr12 steel with

quenched treated 60-62

2).Cutting system: advanced hydraulic drive, automatic cutting

after forming, no distorting or

wasting, high level safety factor.

It adopts the hydraulic drive and automatic encoder to cut the

accurate length you set on the computer.The tolerance is within

10m±1mm

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components:It contains one set of blade, one hydraulic tank and one

cutter machine

5.Computer controlling part of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine

1).PLC brand: Normally, it is Delta. Mistubishi, Panasonic, Siemens

are optional.

2).working model: fully automatic and manaul

3).working language: normally are English, Chinese,Russia. Can be

set as per your requirements.

6. Hydraulic station of the Garden Fence Panel Making Machine/ Metal Fencing Cold Forming Machine 1).including one motor,one oil tank,one magnetic valve,one pressure gage, hydraulic oil tube

2).3kw,4kw,5.5kw,will be adopted as per your profile sheet.

Why choose us ?

1. We are professional manufacturer, so we can offer better price and after-sale service and shorter delivery time.

2. We have strong design & technical ability, we can design and manufacture as customer's requirement.

3. Our factory has been approved ISO 9001 certificate.

4. We have much experience for installation and training experience overseas.

5. We have successfully exported our machines to more than 90 countries, We all get good feedback.

6. We provide a free two years warranty for all our items.

7. OEM brand.

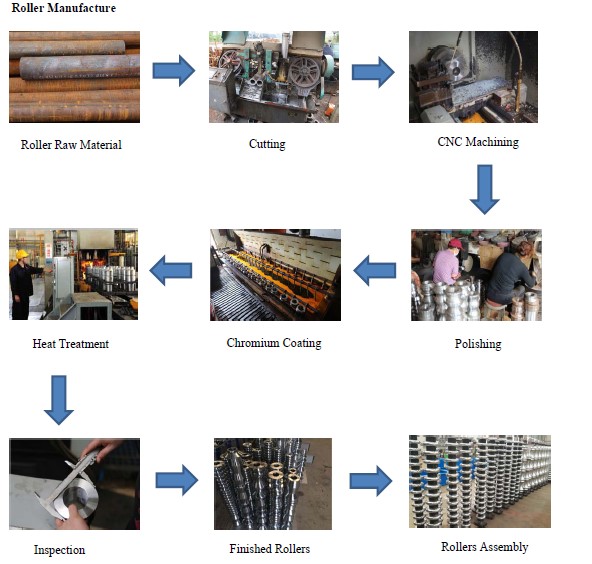

Process Flow