Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

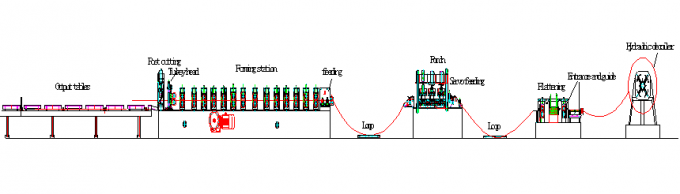

Working Flow:

Hydraulic decoiler→ entrance table &guide→flattening→loop→servo feeding→Punching 1→Punching 2→Punching 3→loop →feeding→roll forming→post cutting →output table

| No. | Main Parameter of Door Frame Roll Forming Machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 220mm |

| 3 | Rollers | 17 rows |

| 4 | Dimensions | 8200*1450*1510mm |

| 5 | Power | 7.5+4kw |

| 6 | Thickness of the plate | 1.2mm |

| 7 | Productivity | 10-15m/min |

| 8 | Material of the cutting blade | Cr12 |

| 9 | Diameter of the roller | Φ70mm |

| 10 | Weight | About 3.4T |

| 11 | Voltage | 380V 50Hz 3phases |

| 15 | Control system | PLC control |

2. Machine Components

1: 3T hydraulic decoiler | |

Single unrolling machine, one side can put material | |

Adopt automatic hydraulic system for expand | |

Coil weight (Max) | 3000kg |

Inter diameter | 420mm-510mm |

Maximal out diameter | 1300mm |

Oil cylinder dia | 100mm |

Coil width (Max) | 500mm |

Working speed | 0-15m/min adjustable |

Main motor power | 4KW AC motor |

Hydraulic power | 3kw |

Frequency converter brand | Yaskawa |

De-coiler should be with Loop control and hold down, and with

baffle for forbid coil fall down | |

The decoiler has 4 segments | |

Color | blue |

Quantity | 1 set |

2: Entrance table guide→flattener | |

Armed adjustable center of the forming rollers and of sufficient

length to prevent lateral movement of the strip on its entry to

flattene | |

Entrance table-guide | adjustable |

Entrance width range | 150-300mm |

Entrance and guide roller | diameter is ¢65mm, material is sae1045, HRC48-52° surface with

chrome |

Quantity | 1 |

The quantity of leveler rolls must be planned according to

thickness 0.8mm to 1.5 mm. | |

Flattener roller: upper is 3 rollers, down is 4 stations(total is 7

rollers) | |

Flattener roller material | SAE 1045 thermal treatment hardness 48-52 HRC |

Diameter of flattener shaf | ¢56mm, material is SAE 1045, hardening and tempering |

Power | 4KW AC motor |

Speed | 0-15m/min |

Speed controlled by frequency converter brand | Yaskawa |

Color | main color in blue, drive parts by yellow |

Quantity | 1 |

3: Servo feeding and punching system | |

Servo feeding system | |

This system adopt servo feeding to make high speed and precision | |

Servo power | 3KW |

Servo brand | Yaskawa (made in China) |

Feeding roller | SAE 1045 thermal treatment hardness 48-52 HRC. |

Feeding material requirement | width min 150mm |

Material spec | thickness between 0.8mm and 1.5mm |

Punching (include hydraulic station) | |

Base on customer provide punching drawing, this machine need adopt

5 units hydraulic punching system | |

Hydraulic station with Storage tank for provides pressure oil

quantity in a short period of time, to meet the requirements of

speed pressure | |

The whole punching operation should be automated and controlled by

a program installed in the PC which is located in the operator's

console. | |

Hydraulic power | 7.5kw |

Working pressure | 12-20Mp adjustable |

4:Feeding→roll forming→rectify device→post cutting | |

Feeding | |

Profile steel thickness | between 0.8mm and 1.5mm |

Feeding system | adjustable by hand wheel |

Feeding width range | 150-300mm |

Feeding roller | diameter is ¢56mm, material is ASTM52100, HRC58-62egeree |

roll forming | |

Main motor power | 5.5kw, AC motor, side motor to save space |

Machine Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Roll station | 17stations (base on final design) |

Roller material | Gcr15, 58-62,HRC hardness and chrome plated surface |

Shaft diameter | ¢65mm material: SAE1045 |

rectify device | |

two station safter roll forming, | |

Function | for revise the end product up and down/ left and right to

straightness |

Roller material: Roller material | GCR15 quenched 58°-62°finishing turning CNC |

Adjust by hand wheel | |

Post cutting system | |

Cutting after forming | Cut the sheet after roll forming to required length |

Material of blade | Cr12, 58-62 HRC hardness |

Cutting blade | 1 set |

Cutting power | by hydraulic, 7.5KW with Storage tank |

Working pressure | 10-20Mpa adjustable |

Length measuring | Automatic encoder length measuring, brand: Omron |

5: Output table | |

Frame | welding by tube |

Size | about 2.0m long*0.3mwide*0.9mhigh |

One out table with support roller | |

Supporter roller | ASTM 1045 with chrome |

Diameter of rollers | 55mm |

Color | Blue |

Quantity | 2 units |

6: hydraulic station | |

Hydraulic power | 7.5kw |

Working pressure | 12-20Mp adjustable |

Solenoid valve | 6 groups (one for cutting) |

Hydraulic oil | 46# hydraulic oil |

Quantity | 1 |

Color | blue |

7: Control desk | |

Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Control panel | Button-type switch and touch screen |

Unit of length | millimeter (switched on the control panel) |

Language | English/Chinese |

PLC brand | Panasonic |

Frequency converter brand | Yaskawa, quantity: 1 |

Touch screen | Taiwan Weinview |

Tag:

Glazed Tile Roll Forming Machine,cold Roll Forming Equipment

| NOTICE |

| Please read following tips carefully. |

| ABOUT AFTER SALES SERVICE: |

| 1. Machine to be installed and commissioned by our technicians. We can send our technician to install the machine accordingly if the buyer need. |

| 2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD100/person/day for salary. |

| 3. Technician: Normally need one or two technician. |

| 4 Training time: one week (contains the time of installation and adjustment) |

| 5. It is in same condition if the buyer need the seller to send the interpreter. |

| GUARANTEE: |

| 1. Warrenty period: Except the wearing parts, 12 months guarantee for machine and 6 months guarantee for electric appliance after shipment. During guarantee time, if the parts are broken caused by the product problem, seller will offer the parts by free,and we will provide the technical support for the whole life. 2. Breakage problem: If the parts were broken caused by the mishandling by buyer, buyer needs to buy the parts from seller. |