Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Galvanized Steel Barrel Type Roof Sheet Making Machine High Frequency PLC Control

Technical parameter

1 | Suitable to process | GI,PPGI |

2 | Type of the product | right angle steel (as your need) |

3 | Thickness of the plate | 0.14-0.8mm |

4 | De-coiler | opinional |

5 | Rollers for forming | 9 rows |

6 | Diameter of the roller | 74 mm |

7 | Rolling material | GCr15 |

8 | Main motor power | 8-11kw,5# |

9 | Productivity | 8-12m/min |

10 | Cutting method | Hydraulic mould cutting |

11 | Material of the cutting blade | Cr12 |

12 | Hydraulic cutting power | 3kw |

13 | Processing precision | Within 1.00mm |

14 | Control system | Delta PLC control |

15 | Side panel of machine | 14mm |

16 | Main structure of the machine | 300 H steel |

17 | Weight | About 2.0T |

18 | Dimensions | 6000*2000*1506mm |

19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

Main Components

| No | Name | Quantity |

| 1 | 5 ton passive de-coiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Control box | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | Out tables | 2 units |

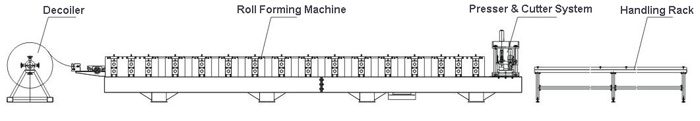

Working Flow of Roll Forming Machine

A.Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B.Servo Feeding

Applicator............................................To feed the

material accurately

C.Hydraulic/Press

Punching...........................................To punch as

requirements

D.Roll Forming

Unit.........................................................To

roll form as requirements

E.Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output

Table................................................................Support

the finished products

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

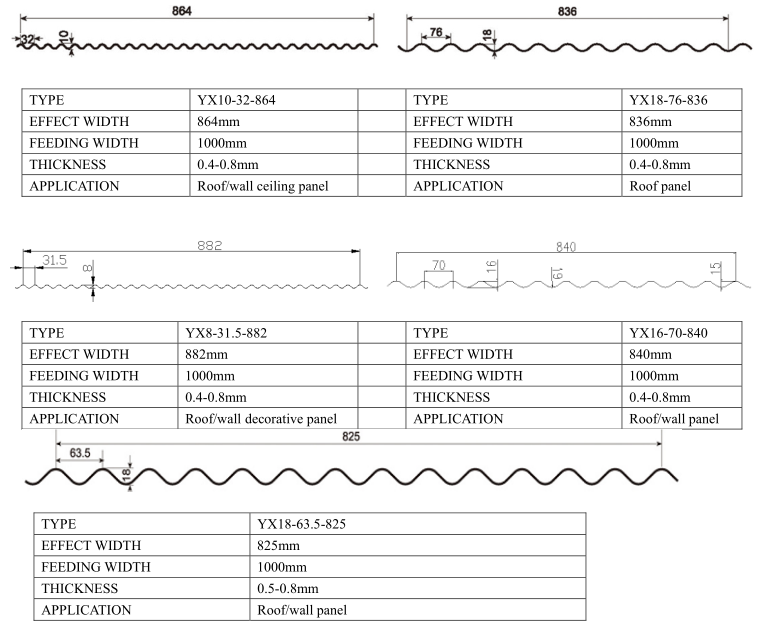

Profile and drawing of product:

Machine Photo