Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

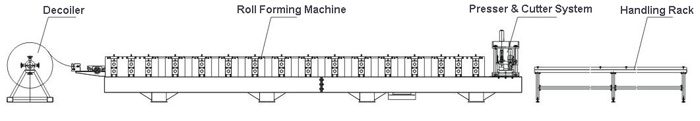

0.5-1.0mm Thickness Steel Profile Drywall Wall Angle Roll Forming

Machine With Hydraulic Punching PLC Control

Machine Technical Parameter

| Items | Specifications |

Material of coil | Material Thickness | 0.5-1.0 mm |

De-coiler | Weight | 3 ton manual |

Forming system | Rolling Speed | up to 15m/min |

Roller Stations | About 13 stations forming | |

Roller Material | Gcr15 Steel with quenching | |

Shaft Material | 45# Steel | |

Maim Motor Power | 7.5 kw | |

Hydraulic cutting Power | 4 kw | |

Cutting | Material Of Cutting | CR12 with quench treatment |

Hardness | HRC58-62 | |

Tolerance | +-1.5mm | |

Cutting blade | 1 set of cutting blade | |

Electrical control system | Electric Source | 380V, 50HZ |

Control System | PLC with touch screen Japanese Panasonic and Yaskawa Brand | |

| Weight | About 3.5 tons |

| Way Of Drive | 1 inch single chain |

| Size of machine | Length 3100mm* Width 500mm* Height 700m |

Main Components

3 ton passive de-coiler:1 set

Feeding with guide:1 set

Main roll forming machine:1 set

PLC Control system:1 unit

Hydraulic station:1 unit

Stop cutting device:1 unit

Safety cover:1 unit

Out table:2 units

Spare parts:1 package

Working Flow of Roll Forming Machine

feeding with guide—Roll forming——Cutting—Products collecting

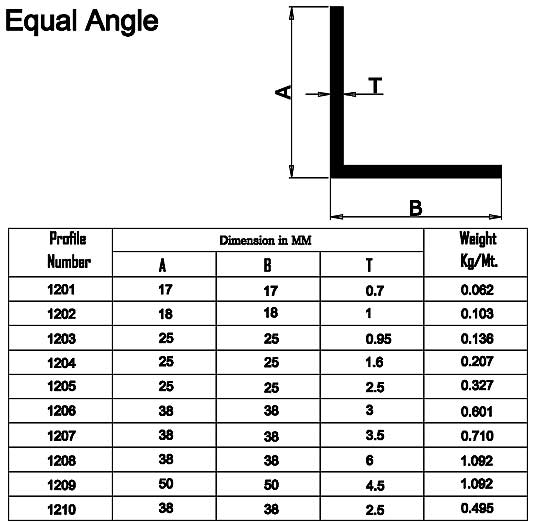

Standard Profile and Drawing Of Product

Photo Gallery

Competitive Advantage

1. save space

2. easy installation

3. perfect service

4. excellent quality

5. Operate easily