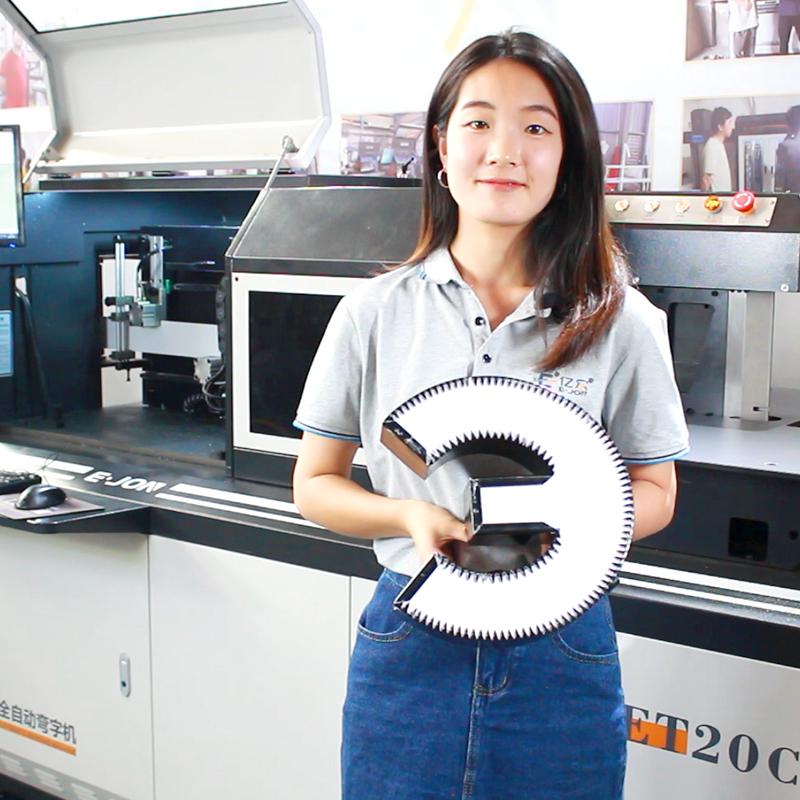

Tianjin Ejon Flying Science And Technology Co., Ltd. |

|

Verified Suppliers

|

|

ITEM | VALUE |

Working Space | 2400mm*1100mm*1500mm |

Weight (KG) | 700 |

Power | AC220V、50Hz、2.0kW |

File Format | Dxf.Plt.Ai |

Function | Auto Feeding+bending+slotting+notching |

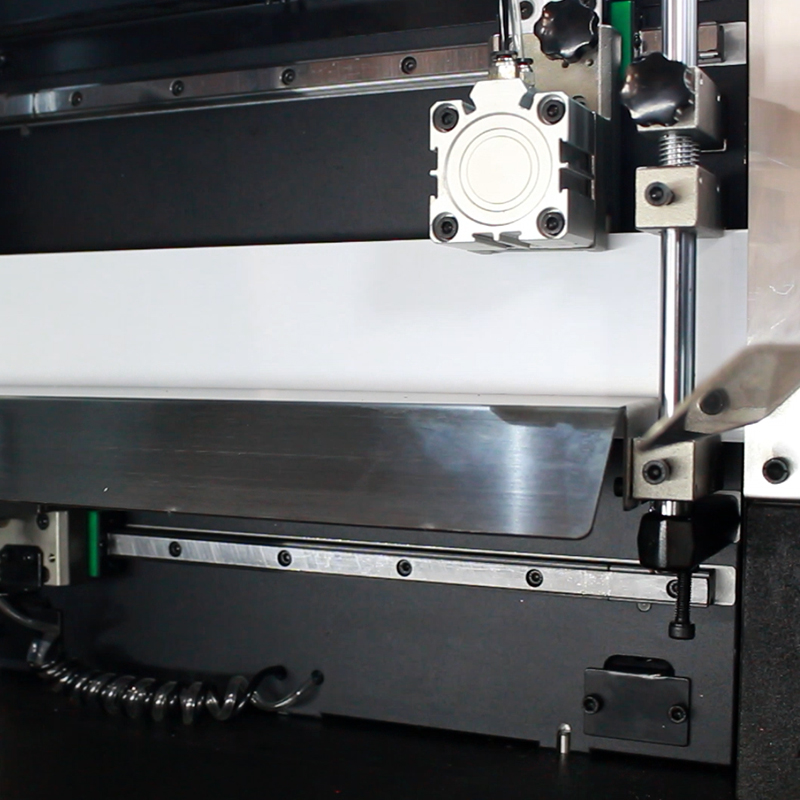

Feeding System | Mechanical hands circulating clamping feeding |

Accuracy | ±0.1mm |

Control System | 7 axis control system (3 servo axis control) |

Bending System | Double Blades Alternate Bending System |

Suitable Material | Stainless steel, galvanized plate, Aluminum plate |

Bending Thickness | 0.4~1.2 mm |

Min. Bending Angle | R6 |

Slotting System | Plane cutter/milling wheel cutter |

Slotting Trip | 20~200mm |

Item | Value |

Package Size | 1410mm*780mm*1600mm |

Packing material | fumigated wooden case, PE film or according to customer's special

request |

Weight | 750kg |

Port | Tianjin port |

Lead Time | 1 Set: 7 days 2 Sets: 15 days >2: To be negotiated |

Freight way | shipping, Land transportation |