Tianjin Ejon Flying Science And Technology Co., Ltd. |

|

Verified Suppliers

|

|

MAIN CHARACTERISTICS OF EJON YZ916 | ||||||||

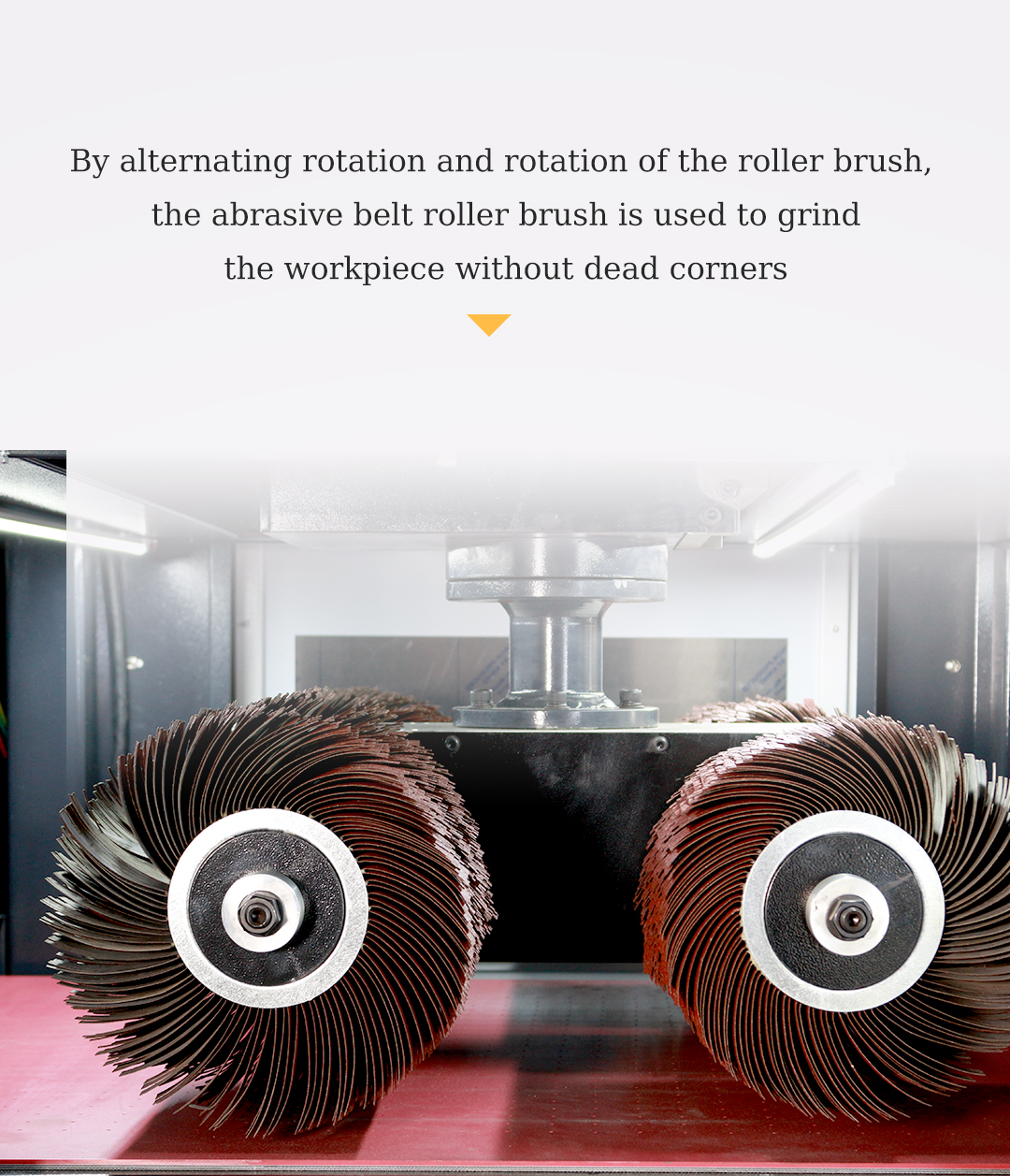

1. More convenient setting. Integrated function setting+LED touch screen. 2. Lower material cost. Universal sand belt wheel can last 2~3 months; multiple sand belt

wheels (80~150 molybdenum) are available. 3. Safe. No need to contact with materials during operation, metal debris

is blocked in the cabinet and will not splash freely. 4. Clean. Dust and debris can be connected to the dust removal system. 5. Multiple choices. For magnetic-capable material processing, magnetic adsorption

function is standard configuration, greatly reduce device power

consumption; For materials that cannot be magnetically attracted,

vacuum negative pressure workstation can be selected for adsorption

processing. 6. Parameters visual adjustment. The grinding and stroke parameters can be freely adjusted

visually, can only grind the contour and sharp edge of the

workpiece without damaging the surface. | ||||||||