Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

Portal Frame Steel Warehouse Buildings / Prefab Metal Maintenance Workshop Buildings

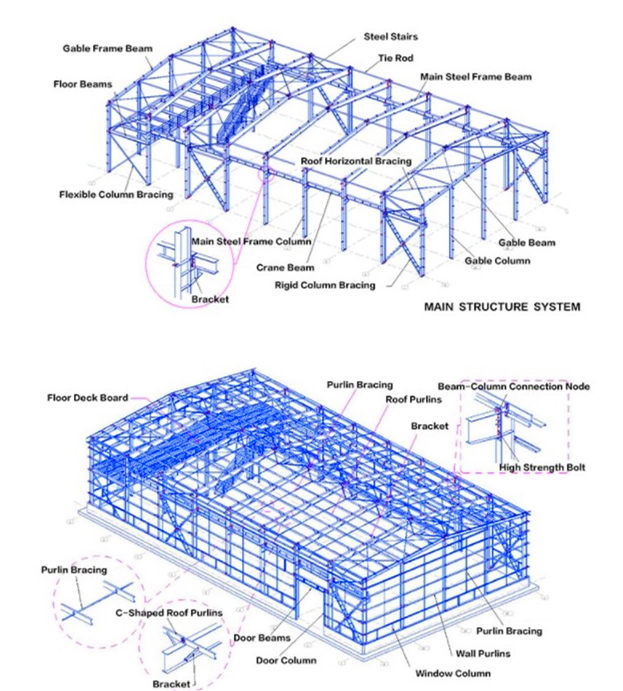

Portal Frame Steel Warehouse Buildings / Prefab Metal Maintenance Workshop Buildings. This is a Light Metal Shop Buildings Steel Structure Factory Buildings For Auto Repair Shops. The steel frame structure of this light metal shop buildings is weld H-section steel columns and beams. Glass wool sandwich panel is used as roof and wall insulation panels.

Prefabricated gable frame steel structure building can be applied to factories, warehouses, workshop buildings, hangars, etc. Suitable for single-story, large-span buildings. The building is simple, the construction period is short, all the components are prefabricated in the factory, which greatly shortens the construction period. The cost is reasonable, the steel structure is light in weight, the foundation cost is reduced, the construction speed is fast, and it can be completed and put into operation as soon as possible. The comprehensive economic benefits are much better than the concrete structure buildings.

Name | Portal Frame Steel Warehouse Buildings / Prefab Metal Maintenance Workshop Buildings |

Structure Type | Gable frame, single ridge, two spans |

Length | 80m |

Width | 40m |

Eave Height | 11m |

Roof Slope | 10% |

Gable Wall Column Spacing | 7.5m |

Roof | Glass wool sandwich panel |

Wall | Glass wool sandwich panel |

Door | Sliding door |

Window | Ribbon Skylight |

Height difference between indoor and outdoor | 300mm |

Main Parts | Item Name | Specification |

|

| Q235B, Q345B |

H shape, Box, Steel pipe, Hot rolled sheet | ||

| Q235B, Q345B | |

H shape, Steel Truss, Hot rolled sheet | ||

| Q235B, Q345B | |

Steel rod, Steel pipe, Angle steel | ||

Roof Purlin | C or Z shape, Steel purlin | |

|

| Q235B, Q345B |

C or Z shape, Steel purlin | ||

Roof | Single colorful corrugate steel sheet, Sandwich panel with EPS, Rock wool, PU, Glass wool etc., | |

Wall | Single colorful corrugate steel sheet, Sandwich panel with EPS, Rock wool, PU, Glass wool etc., | |

| Bolts | Ordinary, High strength |

Gutter | Galvanized Steel plate, Stainless steel | |

Windows | Aluminum alloy-Glass, Aluminum alloy-shutter, PVC | |

Doors | Sliding or Rolling door | |

Downpipes | PVC pipe, Color steel pipe | |

Edge Cover | Made of color steel sheet thickness 0.5mm | |

Ventilator | Stainless steel | |

Crane | Crane in 5 tons to 30 tons |

The floor space of our steel structre fabrication factory is 35,000㎡, and the workshop area is 20000㎡. We own three light/heavy H steel production lines, BOX production lines, C/Z purlin production lines and various types of profiling steel sheet machines with advanced equipment such as plasma cutting machine.

We can design and fabricate customized steel structure components for light and heavy steel structure buildings in protal frame and dome frame, such as warehouse, workshop, storage, hangar, chicken shed, steel shed for market and ground parking, supermarket , high rise steel office buiding, factory , plant, exhibition hall, gym, dormitory building, oli&gas, power station, infrastructure buildings, etc.

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40’HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

The following question we need to know before making the price. Just feel free to fill what you know.

1 | Location (where will be built?) | _____country, area |

2 | Size: length*width*height | _____mm*_____mm*_____mm |

3 | wind load (max. wind speed) | _____kn/m2, _____km/h, _____m/s |

4 | snow load (max. snow height) | _____kn/m2, _____mm |

5 | anti-earthquake | _____level |

6 | brickwall needed or not | If yes, 1.2m high or 1.5m high |

7 | thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be

suggested; . if not, the metal steel sheets will be ok. The cost of

the latter will be much |

8 | door quantity & size | _____units, _____(width)mm*_____(height)mm |

9 | window quanity & size | _____units, _____(width)mm*_____(height)mm |

10 | crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |