Anping tenglu metal wire mesh co.,ltd. |

|

Stainless Steel Wire Mesh in Plain Weave,woven stainless steel wire mesh,304 316 stainless steel netting

www.stainlesssteelwiremeshfactory.com.

Material: 302, 304, 304L, 316, 316L, etc.

Wire diameter: 0.02-2.03mm.

Mesh size: 1*30m, 1.2*30m, 1.5*30m, 1.6*30m, 2*30m, etc.

Woven type: plain, twill, ducth.

Material

SS 430: Non Nickel and have magnetic;

SUS 202: non-magnetic, low anti-corrosion resistence;

SUS 304/304L: low-magnetic, good anti-corrosion resistence;

SUS 316/316L: low-magnetic, better anti-corrosion resistence;

SUS 310S: anti-oxidization,anti-corrosive and high temperature

resistence

Type 304: often refers to as 18Cr, 8 Ni, Type 304 is the basic stainless

alloy mostly commonly utilized for wire cloth weaving. It

withstands outdoor exposure without rusting and resists oxidation

at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304:

Is very similar to Type304, the difference being the reduce carbon

content for better weaving and secondary welding characteristics.

Type 316: Stabilized by the addition of 2% molybdenum, Type 316 has better

resistance to pitting corrosion than the chromium-nickel stainless

steels where brines, sulfur-bearing water or halogen salts, such as

chlorides are present.

Type 316L: Is very similare to type 316, the difference being the reduce

carbon content for better wire cloth weaving and secondary welding

1) Weaving Styles:

Weave type

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most

basic type of weaves. In plain weave, the warp and weft are aligned

so they form a simple criss-cross pattern. Each weft thread crosses

the warp threads by going over one, then under the next, and so on.

The next weft thread goes under the warp threads that its neighbor

went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the

warp yarns in a progression of interlaces to the right or left,

forming a distinct diagonal line. This diagonal line is also known

as a wale. A float is the portion of a yarn that crosses over two

or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have

different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have

different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp

wires and less weft wires.

weaving and characteristics: plain weaving twill weaving/dutch weaving

Application: used in mine,oil,chemical industry , food industry,

pharmaceutical industry and machine producing.

| Specification list of Stainless Steel Wire Mesh / Woven Wire Cloth | |||||

| Meshes Per Linear Inch | Diameter of Wire | Width of Opening | Open Area, % | ||

| Inches | mm | Inches | mm | ||

| 10 x 10 | 0.047 | 1.2 | 0.053 | 1.34 | 28.1 |

| 10 x 10 | 0.035 | 0.9 | 0.065 | 1.65 | 42.3 |

| 10 x 10 | 0.032 | 0.8 | 0.068 | 1.27 | 46.2 |

| 10 x 10 | 0.025 | 0.63 | 0.075 | 1.90 | 56.3 |

| 12 x 12 | 0.041 | 1.0 | 0.042 | 1.06 | 25.4 |

| 12 x 12 | 0.035 | 0.9 | 0.048 | 1.22 | 33.2 |

| 12 x 12 | 0.032 | 0.8 | 0.051 | 1.29 | 37.5 |

| 12 x 12 | 0.028 | 0.7 | 0.055 | 1.39 | 43.6 |

| 12 x 12 | 0.023 | 0.58 | 0.060 | 1.52 | 51.8 |

| 14 x 14 | 0.032 | 0.8 | 0.039 | 1.52 | 29.8 |

| 14 x 14 | 0.025 | 0.63 | 0.046 | 0.99 | 41.5 |

| 14 x 14 | 0.023 | 0.58 | 0.048 | 1.22 | 45.2 |

| 14 x 14 | 0.020 | 0.5 | 0.051 | 1.30 | 51.0 |

| 16 x 16 | 0.028 | 0.7 | 0.035 | 0.89 | 30.5 |

| 16 x 16 | 0.023 | 0.58 | 0.040 | 1.01 | 39.9 |

| 16 x 16 | 0.018 | 0.45 | 0.045 | 1.14 | 50.7 |

| 18 x 18 | 0.020 | 0.5 | 0.036 | 0.91 | 41.1 |

| 18 x 18 | 0.018 | 0.45 | 0.038 | 0.96 | 48.3 |

| 20 x 20 | 0.023 | 0.58 | 0.027 | 0.68 | 29.2 |

| 20 x 20 | 0.020 | 0.5 | 0.030 | 0.76 | 36.0 |

| 20 x 20 | 0.018 | 0.45 | 0.032 | 0.81 | 41.0 |

| 20 x 20 | 0.016 | 0.40 | 0.034 | 0.86 | 46.2 |

| 24 x 24 | 0.014 | 0.35 | 0.028 | 0.71 | 44.2 |

| 28 x 28 | 0.010 | 0.25 | 0.026 | 0.66 | 51.8 |

| 30 x 30 | 0.013 | 0.33 | 0.020 | 0.50 | 37.1 |

| 30 x 30 | 0.012 | 0.30 | 0.021 | 0.53 | 40.8 |

| 35 x 35 | 0.012 | 0.30 | 0.017' | 0.43 | 33.8 |

| 35 x 35 | 0.010 | 0.25 | 0.019 | 0.48 | 42.4 |

| 40 x 40 | 0.014 | 0.35 | 0.011 | 0.28 | 19.3 |

| 40 x 40 | 0.012 | 0.30 | 0.013 | 0.33 | 27.4 |

| 40 x 40 | 0.010 | 0.25 | 0.015 | 0.38 | 36.0 |

| 40 x 40 | 0.0095 | 0.24 | 0.016 | 0.40 | 38.4 |

| 50 x 50 | 0.009 | 0.23 | 0.011 | 0.28 | 30.3 |

| 60 x 60 | 0.0075 | 0.19 | 0.009 | 0.22 | 30.5 |

| 70 x 70 | 0.0065 | 0.17 | 0.008 | 0.20 | 29.8 |

| 80 x 80 | 0.0070 | 0.18 | 0.006 | 0.15 | 19.4 |

| 80 x 80 | 0.0055 | 0.14 | 0.007 | 0.17 | 31.4 |

| 90 x 90 | 0.0055 | 0.14 | 0.006 | 0.15 | 25.4 |

| 100 x 100 | 0.0045 | 0.11 | 0.006 | 0.15 | 30.3 |

| 120 x 120 | 0.0040 | 0.10 | 0.0043 | 0.11 | 26.6 |

| 120 x 120 | 0.0037 | 0.09 | 0.005 | 0.12 | 30.7 |

| 150 x 150 | 0.0026 | 0.066 | 0.0041 | 0.10 | 37.4 |

| 165 x 165 | 0.0019 | 0.048 | 0.0041 | 0.10 | 44.0 |

| 180 x 180 | 0.0023 | 0.058 | 0.0032 | 0.08 | 33.5 |

| 180 x 180 | 0.0020 | 0.050 | 0.0035 | 0.09 | 41.1 |

| 200 x 200 | 0.0020 | 0.050 | 0.003 | 0.076 | 36.0 |

| 200 x 200 | 0.0016 | 0.040 | 0.0035 | 0.089 | 46.0 |

| 220 x 220 | 0.0019 | 0.048 | 0.0026 | 0.066 | 33.0 |

| 230 x 230 | 0.0014 | 0.035 | 0.0028 | 0.071 | 46.0 |

| 250 x 250 | 0.0016 | 0.040 | 0.0024 | 0.061 | 36.0 |

| 270 x 270 | 0.0014 | 0.040 | 0.0022 | 0.055 | 38.0 |

| 300 x 300 | 0.0012 | 0.030 | 0.0021 | 0.053 | 40.1 |

| 325 x 325 | 0.0014 | 0.040 | 0.0017 | 0.043 | 30.0 |

| 325 x 325 | 0.0011 | 0.028 | 0.0020 | 0.050 | 42.0 |

| 400 x 400 | 0.0010 | 0.025 | 0.0015 | 0.038 | 36.0 |

| 500 x 500 | 0.0010 | 0.025 | 0.0011 | 0.028 | 25.0 |

| 635 x 635 | 0.0009 | 0.022 | 0.0006 | 0.015 | 14.5 |

Feature

1. Uniform mesh openings are suitable for filtration.

2. Flat and smooth surface with no sharp edges, burrs or acute

angles.

3. High pressure and temperature resistance in reference to

materiel selected.

4. Excellent flexibility are capable to forming the shape that you

want.

5. Wide range of application: filtration, protection, decoration,

art appreciation, etc.

6. Long service life. The raw material that we make the woven wire

mesh meets the international standards. And if you need, we can

provide the quality certification.

7. Easy maintenance. Woven wire mesh made of metal will need

minimum maintenance compared with woven wire mesh made of cloth.

Application

1. Woven wire mesh is commonly used for filtration, protection

decoration and art appreciation. And it can be used in construction

industry, petroleum industry, coal industry, agricultural and food

industry, etc.

2. Woven wire mesh can be made into filter disc or filter cartridge

for gas, liquid or slurry filtration.

3. Woven wire mesh can be made into window screen or door screen

for mosquito prevention and decoration.

4. Woven wire mesh can be made into multiple types of wire mesh

crafts for decoration and appreciation.

5. Woven wire mesh can be made into decorative wire mesh for space

dividing or building protection.

Package

6. Woven wire mesh is rolled on the paper core, then wrapped with

craft paper and a layer

Processing products

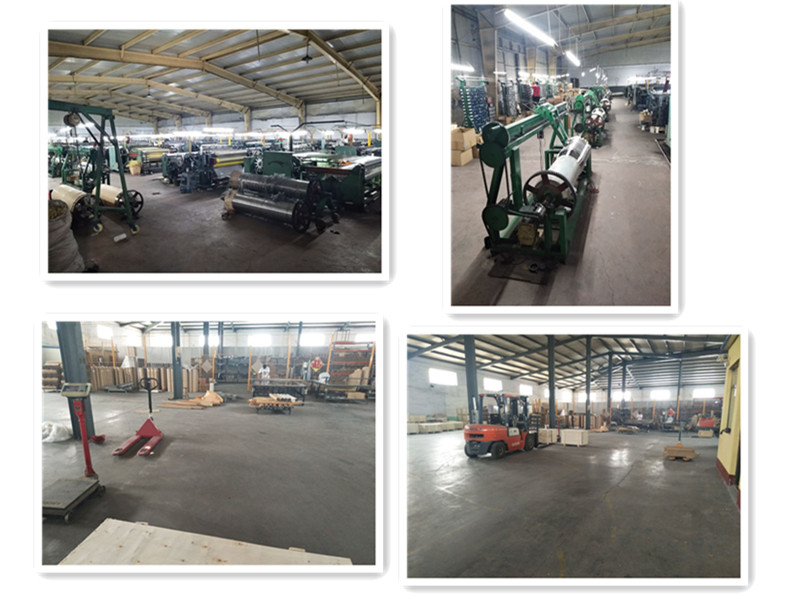

Concentrating on putting all the efforts into maintaining product

standards. We have a full range of production equipment, advanced

technology, scientific management and inspection systems so that we

can meet the exact requirements of our customers for various of

wire mesh products.

About us