LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

2000kg/h Thailand Tapioca Pellet Mill Machine 6p 110kw Tapioca Pellet Machine

Tapioca root tubers are used as energy feed - Tapioca pellets, which have the same nutritional content as Tapioca. Tapioca pellet feed is a widely used and cheap energy feed. It is the best energy (corn and wheat) substitute in the case of high grain prices and is widely recognized in feed. At present, it is mainly used in animal feed such as cattle, sheep, chickens, etc.

Main specs of tapioca pellet mill machine drzl420

| 1 | Model | DRZL420 | ||

| 2 | Machine size | 2900*1320*2300MM | ||

| 3 | Total weight | 3200KGS | ||

| 4 | Output | 2000kgs/H for tapioca pellet making , | ||

| 5 | Ring die size | Inner diameter :420mm | ||

| 6 | Asistance Power | 2.2kw+1.1 kw | ||

| 7 | Main power | 110kw ,6p . Other biomass and waste :90kw ,8p (380v, 50hz ) | ||

| 8 | Bearing | Body inside :FAG OR SKF | ||

| 9 | Pellet size | φ6mm-φ12mm | ||

| 10 | Roller Qty | 2 pcs | ||

| 11 | Cooling method | Oil cooling ,real 24 hours running . | ||

| 12 | Pellet molding rate | >=95% | ||

| 13 | Oil seal | Taiwan original oil seal | ||

| 14 | Pellet Length | Adjustable by cutter

| ||

| Including :One Ring Die ,two roller shell . | ||||

Highlight :

1. Water content can arrange from 10-20%.

2. No dust go into side of machine . If dust inside ,will change gear with much time and labor .

3. Easy maintenance . Less time to change pellet die and roller shell .

4. Pattent pellet mill .

Remarks

◆ The above capacity comes from 8mm tapioca pellets production.

◆ The final capacity of tapicoa pellet mil machine depends on the features of raw materials, operation and maintenance,etc.

◆ There are 2 rollers in the pressing chamber.

Except for tapioca pellet making , this machine is also used for biomass such as rich husk , straw pellet machine ,wood waste such as sawdust ,baoboo ,hard and soft wood pellet making .

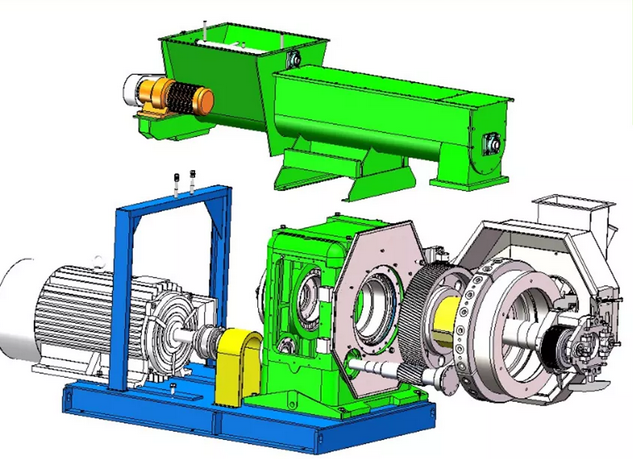

Structure of 2000kg/h Thailand Tapioca Pellet Mill Machine 6p 110kw Tapioca Pellet Machine

(Compression Ratio= L/D L: Effective Die Hole Pelleting Length; D:

Effective Die Hole Dia)

Generally speaking, the higher the compression ratio, the denser

the finished pellets. But it does not mean that the higher the

compression ratio, the better the pellet quality. Compression ratio

should be calculated based on your raw material for making pellets.

Commonly compression ratio is inversely proportion to the hardness

of raw material, the harder the raw material, the smaller the

compression ratio.

How to work of 2000kg/h Thailand Tapioca Pellet Mill Machine 6p 110kw Tapioca Pellet Machine

The cassave in the granulation bin is fed into the chute by the feeding auger, the material enters the wood press chamber through the forced feeder, and is fed into the two pressing areas in the ring die by the feeding scraper. Due to the high-speed rotation of the ring die The material is brought between the ring die and the pressure roller. Under the strong extrusion action of the ring die and the pressure roller, the material is gradually compacted and formed in the die hole. Because the extrusion of the material between the die rollers is continuous , so the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

The Spare parts

1. Ring die :Pellet dies must resist abrasion, corrosion from chemical

exposure and breakage caused by the physical stresses of pellet

formation. The optimum die combines high resistance to abrasion,

breakage and corrosion with maximum productivity. Our expertise

enables us to precisely match the die specification to your

required formulation, even if it means customizing a die pattern to

meet your exact needs.

2. Roller shell :

Each die and roller assembly stay together as a unit, extending die and roller life and enabling easy storage and conversion.

Raw material :alloy steel .

Others such as five piece cover ,o ring ,main shaft etc .

Contact us to get price .