LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

EFB Pellet Making Machine EFB Fiber Pellet Mill 4t/h

Technical Paremater :

1. Type:KLF880(Vertical)

2. Main motor:200KW

3. Capacity:3-4t/h

5. weight:14.2t

6. Dimesion(mm):4000*2000*2400

7. Roller mode :3 roller/self-lock

Cooling method:water cooling or oil cooling,the roller bearing is

guaranteed for 2 years .

EFB is a major biomass source in Malaysia, Serbia, EFB fiber contains much lignin, which is quite important for pellet forming

This pellet mill special designed for fiber raw material such as efb, corn straw ,cotton stalk ,efb ,grass etc . Such as EFB does not need to be finely crushed again. We can roughly cut the EFB to a length of 5-8cm and the EFB FIBER can enter the pellet mill pressing chamber . Or the crushed materials do not need to be finely screened for direct pelletizeing .

The pellet mill can compactly process various agricultural

and forestry biomass wastes and some industrial products' primary

(rough) processing wastes, such as corn straw, cotton stalk, rice

straw, rice husk, peanut shell, leaves, branches, bark, sawdust,

palm silk, mushroom waste sawdust, animal feces, biogas residue,

garbage, etc. into particles or blocks.

Highligh Advantage of EFB pellet mill Machine :

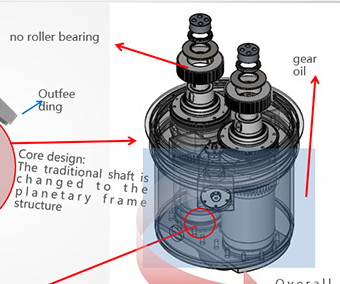

As mentioned above, we are not sealing the assembly as a one-piece package (this requires replacement of the entire press roll assembly, which is expensive), and does not only separate the bearings and separately lubricate them (requires separate cooling devices) , cost and energy consumption increased), we integrated it into the gear box, using gear oil lubrication.

The pelleting chamber space is more than 2 time, and the material adaptability is more extensive.It can be adapted to the granulation of bulk or long fiber clogging materials (such as palm silk, eucalyptus, large shavings and complex plastics, garbage, etc.) without the need for fine pulverization of materials.

Contact us to get the quotation .