Zhengzhou Fangming High Temperature Ceramic New Material Co., Ltd. |

|

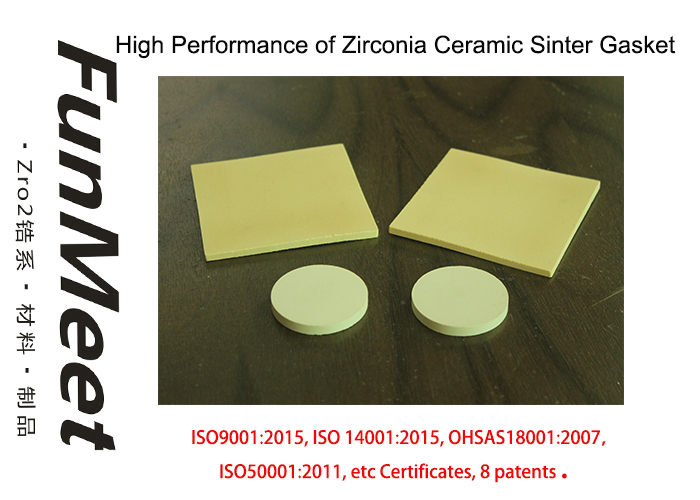

HP Zirconia Composite Ceramic Sintering Gasket- long working life and reuse

Electronic Component substrates Introduction

Electronic substrates are base supports for production of electronic circuits used in applications such as computer chips, multi-chip modules, circuit boards and disk drives. Ceramic substrates are often tape cast or roll compacted into a long thick or thin film flexible sheets. The sheets are cut to size and are then available for a variety of processing steps that may or may not include being punched, filled and laminated scribed and co-fired. Once fired, the substrate or package often receives further processing such as laser machining, lapping, polishing, etching or plating.

Product Features:

Our products are taking super high temperature composite ceramic raw material, through scientific grain gradation, mixing and grinding ,vibrating pressing, high temp. sintering etc. advanced technology and process finished. They have high-temp resisting, stable chemical performance, excellent thermal shock stability, non-wetting and adhered, easy operating, longer-working life etc. Features. Magnesia stablized Zirconia, Y2O3-ZrO2 composite and HP Y2O3 ceramic qualities are what we are usually supplying.

Product's application:

1.Capacitor etc. Electronic component substrate sintered.

2.Barium Titanate material sintered.

3.Metal powder, Ti series powder sintered.

Products Shape and Size

We can produce the various shapes and sizes of the zirconia composite sintering gasket according to the client's demand about the drawing and sizes.

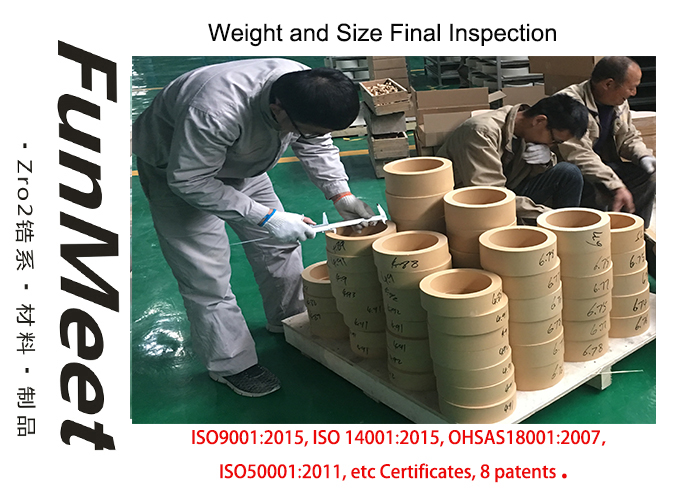

Size Tolerance

The size tolerance of the zirconia sintering gasket is +-1mm, or according to the client's demand.

Packing Detail

Independent packing with the protecting foam wrapped, and into the carton with protecting foam wrapped, then into the fumigation wooden box.

Company Introduction

Setup in Sep.,2015,Fangming NewM. is one high-new technology producing enterprise of the high purity and the ultra-high temperature new type of thecomposite nano-ceramic materials and products based on the raw material of the zirconia, and the one manufacturer of urgently much needed to breakthrough key technologies in the new materials category advocated and developed by the state in the 2025 planning catalogue, of the rare oxide composite new materials of the super high temperature structural ceramics, which are applied in the extreme environments.