Zhengzhou Fangming High Temperature Ceramic New Material Co., Ltd. |

|

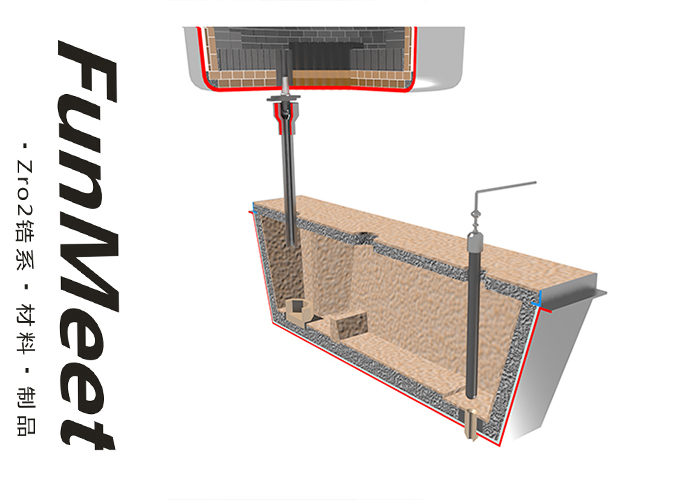

High density of zirconia bowl embedded in Al2O3-C body in Tundish- Flow Control in Crystallizer

Product Function

Our Zirconia Bowl is installed in the bottom of tundish, matched with the upper nozzle of the tundish, to control the flow of molten steel from the tundish to the mold in the continuous casting process, so as to ensure the liquid level stability of molten steel in the mold and the stability of the continuous casting process.

The rod head is the most critical part of the stopper. The rod head and the nozzle bowl cooperate to achieve flow control. The rod head and the nozzle bowl are designed in curved form to ensure good flow control effect and closing function.

Products Features:

Comparing the Al2O3-C, Al2O3-MgO-C,MgO-C, MgO-Spinel etc. materials tundish nozzle, the one embedded our HP Zirconia Insert (Core) has the longer flowing working times continuously, high purity of the 95% Zirconia content, very strong chemical stability at high temp. state, strong erision and scouring of the smelted steel liquid and slag resistance, and strong thermal shock stabilities, etc. obviously features, finally increase the working life of the tundish nozzle, and increase the steel smelting output and efficiency in the steel plants.

Production Process

Our zirconia Insert embedded the alumina carbon body and bonded by the refractory mortar is made of the high purity of zirconia grain and powder,bonding agent, through the the automatic system mixing, drying, Inspecting, pressing, inspecting, sintering at high temperature state , etc. series complex process, then deliver to the china mainland and oversea from our factory.

Inspection times in production process

1.After Mixing, inspect the water content of material,

2.After pressing, inspect the size,missing angle, etc. of semi-finished products

3.After sintering, inspect the size, missing angle, cave, etc. of finished products

4.Before packing, inspect the size, missing angle, cave,of the finished prodcuts again.

Stablizer of the zirconia Insert in the zirconia insert for tundish nozzle.

Up to now, for the tundish nozzle (bowl), what we are using is Magnesia,as the stablizer of the zirconia bowl.

Chemical Composition and Physical Propeties

| Model | Chemical Composition | Physical Properties | ||||

ZrO2+HfO2 (%) | Al2O3 (%) | SiO2 (%) | MgO (%) | Bulk Density (g/cm3) | Apparent Porosity (%) | |

| FMXC-TZ-002 | ≥95 | ≤0.2 | ≤0.4 | ≤2.9 | 5.40-5.50 |

7-8% |

Size Tolerance:

Middle Hole Diamter:+-0.2mm, other sizes: +-1mm.

Fangming NewM Introduction

Fangming NewM is setup in Sep.,2015. We are one high-new technology enterprise of producing the high purity and ultra-high temperature new type of the composite nano-ceramic materials and products based on the zirconia (Zirconia Slide Gate Plate ), and urgently much needed to breakthrough key technologies in the new materials category advocated and developed by the state in the 2025 planning catalogue, the High-New Technology manufacturer of the rare composite new materials of the super high temperature structural ceramics, which are applied in the extreme environments.

Now we have gained the ISO9001:2015 Quality Management System Certificate, ISO14001:2015 Environment Management System Certificate, OHSAS18001:2007 occupational Health&Safety Management System ,ISO50001:2011 Energy Management System Certificate, etc. Certificates.We have owned the 8 related invention patents and utility model patents.

Large size, super special shaped super high temp. zirconia ceramics, we will offer the comprehensive and integrated super high temperature, strong crushing resistance, strong erosion resistance application condition solutions.