Technical Parameters:

| Capacity | T | 50/10 | 75/20 | 100/20 |

| Span | m | |

| Lifting height | Main hook | m | | | |

| | Aux.hook | m | | | |

| Operation method | | Pendent control,wireless control,cabin control |

| | Lifting | Main hook | m/min | | | |

| Aux.hook | m/min | | | |

| Cross travel | m/min | | | |

| Long travel | m/min | | | |

| Lifting mechanism | type | Heavy duty open winch, double girder trolley hoist |

| Working duty | | |

| Power supply | AC | 220/380/400/415/460V,50/60Hz, 3P |

Applications:

Double girder gantry crane for factory yard is normally using in open-air warehouse. It normally

accompanied with particular lifting tools using in the container shipyard.

It has features of beautiful and durable appearance, perfect performance, low cost, easy maintenance,

high adaptability and so on.

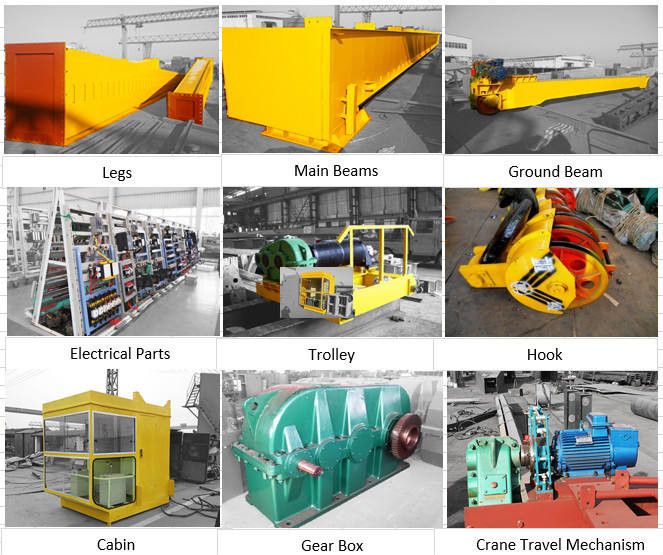

It is composed of beam, support legs, crane traveling mechanism, trolley, electric equipment and so on.

The strong legs shape is like a English Letter ”A”, this design is very benefit when the container pass by

thought the legs.

The control method could be ground control, remote control, cabin control or both.

Packing and Shipping:

Packing:

1. Electric parts are packed by high quality plywood crate to reduce distortion in conveying;

2. Main beams, end beams and electric hoist / winch are packed by plastic woven cloth. It can reduce abrasion when transport.

Delivery:

1. If the size of whole crane are suitable for container ship, usually by container;

2. If the size is too big, usually by bulk ship or by container after truncation;

3. Transport ways are based on reducing cost for you and keep the crane in good condition.

FAQ:

In order to offer you a precisely quotation, please tell us these information:

1.The lifting capacity__ ton?

2.The span length is__ m? (Span=distance between center of two rails)

3.The lifting height is __m? (Lifting height=Distance from hook to ground)

4.What is the lifting speed? (Single speed or double speed)

5.What control mode do you need? (Pendant control or remote control or cabin)

6.What is the power supply in your country? (Our standard power supply is 380V,3Ph,50Hz, other pls indicate)

7.Is there any other special requirements? (If need us to supply rails? how long? etc)