MINGCHENG GROUP LIMITED |

|

Verified Suppliers

|

|

Tin Cure RTV2 Silicone Liquid Rubber For Making Concrete Flower Pot Mold

Product Description

Silicone liquid rubber is called Tin cure silicone rubber which is also called condensation-cure silicone mold rubber, these are high-tear silicone mold rubbers that are known as the “work horse” of the industry because of their performance and economy. Tin cured silicone molds are used for casting wax, cement, gypsum, polymer modified gypsum, resins, etc.

Various Applications of silicone liquid rubber

A: Cultural relic duplication, architectural decoration, statues

B: Resin crafts

C: Lighting ornaments, candles

D: Plaster, Gypsum,Cement,Concrete decorations

F: Model design, product exploitation, etc.

Features of RTV-2 silicone liquid rubber

(1) high tensile & tear strength

(2) Low linear shrinkage

(3) free Curing agent

(4) brushing & pouring

(5) high duplication times

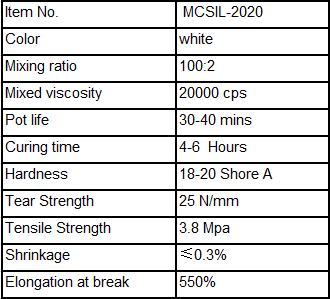

Typical Properties of RTV-2 silicone liquid rubber

Instructions of Silicone Liquid Rubber

1.Correct mixing ratio

Component A is silicone rubber, and component B is curing agent or

vulcanizing agent. Usually the mixing ratio will be 2-3%, e.g. to

100g silicone rubber should be added 2g catalyst and then mix them

thoroughly. (Note: the weight of the silicone and catalyst should

be weighed correctly).

2.Pouring the mixture and curing

Pour the misxed Part A base silicone and CA-30 curing agent as soon as possible onto the original,avoiding air entrapment.The catalyzed material will cure to a flexible rubber within 6 hours(or faster by different mixing ratio or room temperature),we advice you de-mold after 24 hours ,it is will improve the replicate times of silicone mold.

Package of RTV-2 Silicone Liquid Rubber

Part A base silicone: 25kg/drum or 200kg/drum

Part B CA30 Curing Agent: 800g/bottle, 1kg/bottle

Storage & Shelf life

When the silicone rubber is stored at or below 25℃ (77℉) with the original unopened containers, Silicone Base and Curing agent have a usable life of 12 months from the date of production. After 12 months stock, please use the Stir machine to mix the Part A silicone for some minutes, then the silicone can be used again, no influence for other performance.

Certificates: