Dongguan Fulund Intelligent Technology Co., Ltd. |

|

Fully automatic 4 Color 4 Station Screen Printing Machine/ Diy insole T-shirt Press Printer With Related Machines

Fulund has a long history since its establishment in 1999. Due to

the needs of development, the original brand (TYL) expanded the new

brand Fulund in 2022 . Fulund has customers all over the world,such

as international brands shoe manufacturer.

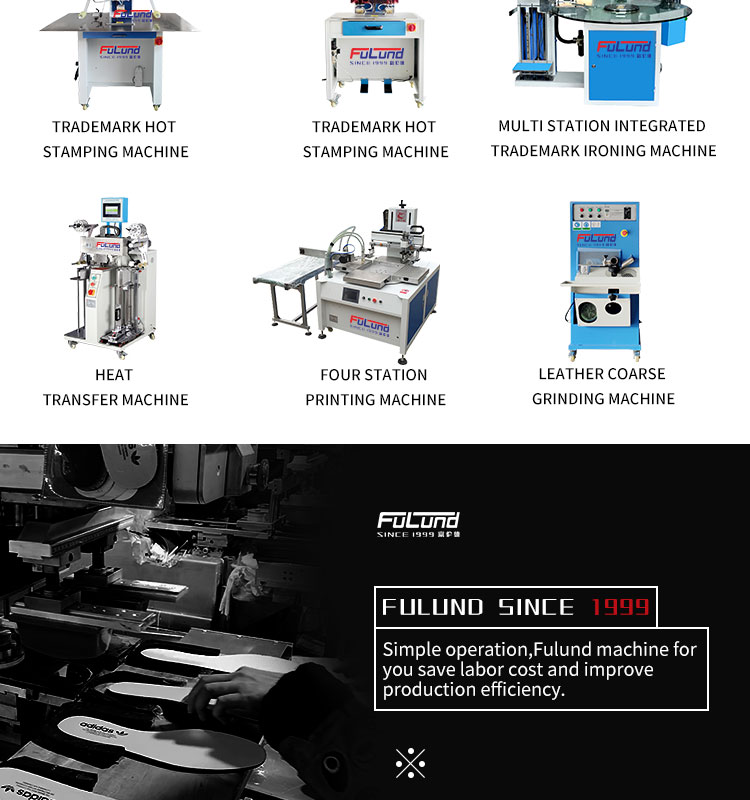

Fulund mainly products: Hot label machine, foam cutting machine,

insole hot stamping machine, shoe tongue transfer hot stamping

machine, insole heat transfer machine, insole cutting and transfer

integrated machine, insole printing machine, silk screen printing

machine, embossing machine, soft rubber equipment , vacuum

vulcanizing machine, silicone labeling machine, glue dispensing

machine, etc.

Features of automatic treadmill screen printing machine:

1. Compared with manual platen printing, the entire printing

process of positioning, scraping, oil return, and shifting of the

walking screen printing machine is fully automatic without manual

intervention, which greatly reduces the labor intensity of the

printing workers.

2. The pressure of the squeegee remains the same, the squeegee

printing is stable, the oil return is uniform, and the printing

color difference is small, which transfers the high dependence of

the printing quality on the printing master.

3. The screen printing machine scratches once every 3 seconds, and

runs continuously for 800-1200 times per hour, which greatly

improves the production efficiency.

4. Optional side-wing dry air drying box can replace the ceiling

fan to blow air in the workshop, and concentrate hot air while

printing and drying, which can save energy and reduce consumption

and reduce production costs while ensuring printing quality.

5. It can be combined with the customer's existing platen to make

full use of existing resources and reduce the cost of technology

upgrades.

6. The printing format from 600mmX800mm to 1800mmX1800mm can be

customized to meet the needs of different printing formats.

7. Mechanical repeatability +0.1mm, overprinting accuracy +0.1mm,

which can meet fine dot printing

8. It is designed with a fast plate-checking device, a fast and

simple plate-changing device. After one plate-checking, there is no

need to repeat the plate-checking, and the production efficiency

will not be reduced due to plate-changing.

9. Using touch screen man-machine interface, a variety of humanized

working modes, specially designed for multiple times of priming

times setting program, priming can be set arbitrarily from 0 to 9

times, the priming process is automatically completed, and the

operation is simple and easy to understand.

10. The three automatic platen screen printing machines only need

one printing master operator, which greatly reduces the labor cost

and solves the major trouble of the current enterprise recruitment

difficulty.

11. The treadmill screen printing machine is generally used for a

single-phase power supply with a power of 220V and 1kw, which is

convenient for energy saving and suitable for more users.

Scope of application:

Widely use in the printing of gloves, insoles, shoes upper, mid-sole, bags and other industries , print the position line, mark line and other various shape of cut-parts .

Features:

1, Automatic printing, automatic receiving, can stack according to the setting quantity, no need manual count and can packaging directly.

2, Manual feeding material , suit for any shape material, broad scope.

3, Positioning rapid, change printing plate easily, simple to operate.

4, Reduce manual printing and receiving process, workers only need put the material, high efficiency, 2 Seconds one time, the efficiency is 1.5 times of the traditional process.

| Model No. | Machine measure(mm) | Wood case measure(mm) | N.W/ G.W (kg) | Capacity | Max printing size |

| FLD-688C | 1740*1500*1530 | 1830*1570*1650 | 450/550 | 1500times/hour | 450*300mm |

| Voltage | Air pressure | Power | Printing thickness | Printing platform | |

| 220V | 4.5~6kpa | 6.9kw | 0~50mm | 600mm |

Contrast:

| Capacity | Feeding way | Receiving way | Printing way | Operator | |

| Traditional machine | 800times/hour | Manual | Manual | Manual put label | 1 |

| FLD-688C | 1500times/hour | Manual | Automatic | Automatic put label | 1 |

Conclustion:Use FLD-688C, four-station, factory can become automatic, one person can operate one set machine, workers only need put the material, no need manual print, can reduce operator fatigue, higher efficiency, can save more labor cost. For example: Monthly labor cost $547, the label cost can save 547x12x1.5=$9846 one year.