Dongguan Fulund Intelligent Technology Co., Ltd. |

|

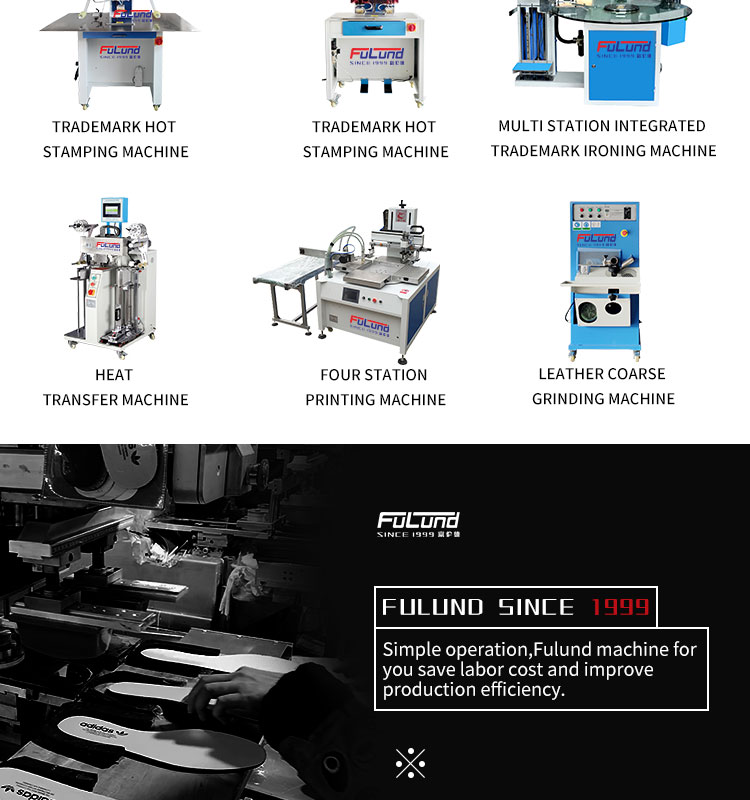

FuLund Factory Printer Garment Shoe Upper Screen Printing Machine

Solar crystalline silicon cell automatic screen printing machine

The automatic screen printing line for solar crystalline silicon

cells is composed of automatic film loading, film storage,

automatic film feeding, machine vision automatic positioning,

automatic printing, automatic loading and unloading and other

systems. The automatic film feeding and receiving system is based

on Connected structure design.

High strength: steel frame and parts to ensure high strength and

stability.

High precision: high precision transmission and matching parts,

servo motor drive printing, high repeat positioning accuracy. Low

vibration: vibration protection of the whole machine, precise

linear guide transmission, to ensure precise and uniform printing.

Low printing pressure: Pneumatically balanced flexible squeegee

printing, digital display automatic pressure compensation

technology, precise control of printing pressure

Anti-fragmentation: The processes of printing, upper and lower

wafers are processed by the latest anti-shatter technology.

Scope of application:

Widely use in the printing of gloves, insoles, shoes upper, mid-sole, bags and other industries , print the position line, mark line and other various shape of cut-parts .

Features:

1, Automatic printing, automatic receiving, can stack according to the setting quantity, no need manual count and can packaging directly.

2, Manual feeding material , suit for any shape material, broad scope.

3, Positioning rapid, change printing plate easily, simple to operate.

4, Reduce manual printing and receiving process, workers only need put the material, high efficiency, 2 Seconds one time, the efficiency is 1.5 times of the traditional process.

| Model No. | Machine measure(mm) | Wood case measure(mm) | N.W/ G.W (kg) | Capacity | Max printing size |

| FLD-688C | 1740*1500*1530 | 1830*1570*1650 | 450/550 | 1500times/hour | 450*300mm |

| Voltage | Air pressure | Power | Printing thickness | Printing platform | |

| 220V | 4.5~6kpa | 6.9kw | 0~50mm | 600mm |

Contrast:

| Capacity | Feeding way | Receiving way | Printing way | Operator | |

| Traditional machine | 800times/hour | Manual | Manual | Manual put label | 1 |

| FLD-688C | 1500times/hour | Manual | Automatic | Automatic put label | 1 |

Conclustion:Use FLD-688C, four-station, factory can become automatic, one person can operate one set machine, workers only need put the material, no need manual print, can reduce operator fatigue, higher efficiency, can save more labor cost. For example: Monthly labor cost $547, the label cost can save 547x12x1.5=$9846 one year.