QINGDAO SHUNHANG MARINE SUPPLIERS CO., LTD. |

|

Verified Suppliers

|

|

Industrial Using Customized Durable Rubber Heavy Lifting Airbags

Product Introduction:

6000 years ago, our ancestor begin to use log-rolling method to lift and move weights, which is still widely used in daily production and actual life nowadays. Marine rubber airbag is designed with soft rubber to lift and carry weights, based on log-rolling method.

Marine rubber airbag is an innovative product of Chinese own proprietary intellectual property rights. It has wide application like ship launching & upgrading, caisson lifting & moving, heavy weights lifting, underwater-engineering buoyancy aid. The marine rubber airbag is not limited to space and heavy machinery, which could efficiently shorten the construction period and save lots of funds.

Heavy lifting airbag is updated based on the ship launching airbags. This update makes heavy lifting airbags are more suitable for heavy lifting and moving work. Heavy lifting airbags have a different structure from the ship launching airbags. It can roll steadily when taking the load.

The heavy lifting airbag is one kind of the toughest inflatable lifting airbag. It can be used for heavy lifting and moving of huge heavy structures, caisson, buildings, etc.

Heavy lifting and transportation relying on heavy lifting airbags are cost-effective and flexible. Heavy lifting airbags will provide you with a unique capability of land transport very large vessels, heavy loads, or heavy construction .

The deflated heavy lifting airbag is very flat and can be placed under a grounded or stranded vessel that is hard aground. As little as 12 inches will provide very quick placement of lifting airbags under the hull.

The structure of Heavy Lifting Airbag:

Structure of Marine Airbag

1. Terminal iron

2. Cone airbag body

3. Cylindrical airbag body

D: Diameter of airbag

L: Valid length of airbag

Loa: Total length of airba

Specifications:

| Some common sizes of our heavy lifting airbags, customized sizes are also available | |||

| Diameter(m) | Effective Length(m) | Layer | Pressure(MPa) |

| 1.0 | 10 | 5~6 | 0.07~0.10 |

| 1.0 | 12 | 5~6 | 0.07~0.10 |

| 1.0 | 15 | 5~6 | 0.07~0.10 |

| 1.2 | 10 | 5~6 | 0.08~0.12 |

| 1.2 | 12 | 5~6 | 0.08~0.12 |

| 1.2 | 15 | 5~6 | 0.08~0.12 |

| 1.5 | 12 | 5~8 | 0.08~0.16 |

| 1.5 | 15 | 5~8 | 0.08~0.16 |

| 1.5 | 18 | 5~8 | 0.08~0.16 |

| 1.5 | 20 | 4~8 | 0.08~0.16 |

| 1.5 | 24 | 5~8 | 0.08~0.16 |

| 1.8 | 12 | 5~8 | 0.08~0.15 |

| 1.8 | 15 | 5~8 | 0.08~0.15 |

| 1.8 | 18 | 5~8 | 0.08~0.15 |

| 1.8 | 20 | 5~8 | 0.08~0.15 |

| 1.8 | 24 | 5~8 | 0.08~0.15 |

| 2.0 | 18 | 6~10 | 0.08~0.18 |

| 2.0 | 20 | 6~10 | 0.08~0.18 |

| 2.0 | 24 | 6~10 | 0.08~0.18 |

| 2.5 | 18 | 7~10 | 0.07~0.13 |

| 2.5 | 20 | 7~10 | 0.07~0.13 |

| 2.5 | 24 | 7~10 | 0.07~0.13 |

Application:

Boat Lifting / Launching / Docking

Industrial foundation lifting and moving

Lifting Capacity

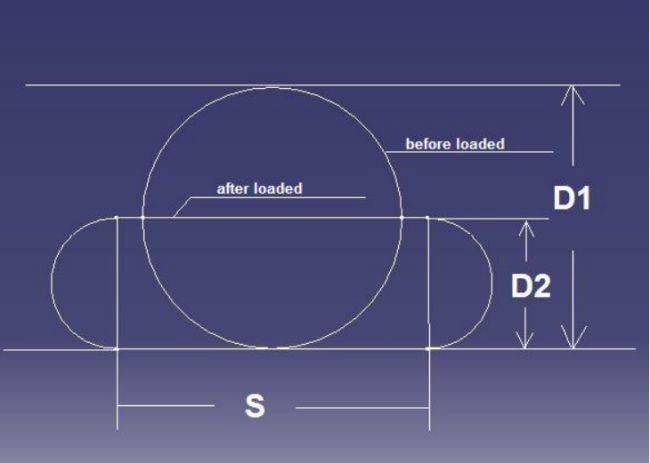

The bearing capacity of heavy lifting airbags were calculated based on the working pressure, contact area. Herein, working pressure was got upon the burst pressure and safety working factor.

Because of the flexibility of rubber airbag, the contact area will be effected by some terms. It inludes carried shipcondition, the different position from gravity center during the process of ship launching and landing. So the bvearing capacity of rubber airbags will vary as well as the contact area.

The approximate bearing capacity can be calculate as follows:

F=PS S=π x (D1-D2)/2

Where:

F is the bearing capacity

P is the working pressure

S is the contact area

P is the percentage of deformation (%);

D1 is the original diamater of the airbag (m);

D2 is the height of the compressed airbag (m)

Attention During Application

1. Working pressure must be controlled strictly, it is not allowed

to exceed the working pressure.

2. No sharp and protruding hard object on the contacting surface of

the airbags, to avoid the puncture on the skin of airbags.

3. Avoid the distortion along the length of airbag.

4. Empty inflating test must be performed if the airbags were not

used for a long time or after reparation. The pressure should be as

same as the testing pressure of our company. Inspectors must be at

least 3 meters away from the airbags. For repaired airbag which was

damaged in large scale, its working pressure should be lowered

reasonably. Besides, annual check should be conducted on airbags

which are used frequently.

5. Don’t drag the airbags on the ground.

Instruction of Airbag Repair

If the airbag is damaged, it can be repaired as long as the rubber doesn’t age seriously(with no crack and stickiness on the surface). And the cords fabric is not loose and rotten. Repair can be made by hot vulcanization or auto-vulcanization. The tolls and repair materials utilized in the former are quite simple. We recommend hot vulcanization, the steps are as below,

1. Wash the airbags to make sure it is clean both inside

and outside and without mud & sand,

oil stain and water logging. Then dry the surface. Note: the

immersion time while washing can’t more than 10 minutes.

2. Mark the repair symbol visibly. Mark the repair area

and the mark area is allowed to exceed 15mm, don’t miss the

concealed damage.

3. Prepare the backing

The material of backing is the same as the airbag and the

arrangement angle of the cord fabric is consistent with the airbag.

The first layer of the backing is a vertical line. Length=(length

of the flaw+50mm)X2

The second layer of the backing is oblique line whose angle is the

same as the airbag. It is 20mm larger than the periphery of the

first layer.

The third layer of the backing is also oblique line whose angle is

opposite to and crosses with the second layer. It is 20mm large

than the periphery of the second layer.

The fourth, fifth and sixth layer may be deduced by analog.

The fillet transition with the radius of 40mm-50mm is required for

the backing periphery of every layer.

If the wound is a nail hole within 100mm or strip wound in 50-70mm,

cross backing shall be prepared. Nylon cross backing is made by

bluing two layers of coated Nylon with the crossing of 90°. Its

size is 200mmX200mm and others are the same as the backing.

4. Filing the wound

File the wound with steel files or flexible shaft filing machine.

The file pattern on the surface should be delicate and even as well

as without any rubber scrap, particle. Filing surface depth is

about 0.5-1mm. The periphery is 20mm larger than the backing.

Breaking and loose is not allowed for filed cord fabric. After

filing, blow always the rubber scrap by brush and compressed air.

5. Brush glue and dry

The whole process must be kept clean. Brush thin glue for the first

time (glue: gasoline=1:8).There should be no sediment and caking,

should be evenly. Forcibly gluing should be performed so that the

glue can penetrate into the cord fabric layer in the file slot. The

gluing should be uniform and obvious scaffold erecting is not

allowed.

6. Viscose

Firstly, brush a layer of base glue with the thickness of 1±0.2mm

on the periphery of the wound. Cool down to not gluing hands, paste

and press and the glue should not be too tight in case glue failure

happens after the new glue contract, then paste the backing. The

center of the backing should be targeted at the wound center. The

angle of the backing should be in consistent with the airbag line

layer. For wound larger than 1M, a layer of coated Nylon fabric

should be pasted to the wound, 25mm lager than the wound. Then

paste the backing. In the end, one sealing rubber (thickness of

0.8-1mm,wideth in 20mm) should be pasted to the cover the joint of

backing edge and body of airbag.

7. Vulcanization

For normal shipbuilding yard, the following simple method can be

adopted: set up a frame, ( as shown in the figure) and provide

plate, sand bag(fill the inner tube of the abandoned automobile

with sand), jack and heated plate(pig iron or steel plate in

Dia300mm ,thickness 25mm). The vulcanized airbag to be repaired

should be targeted to the center in accordance with the position

shown in the figure. First vulcanize the hole and then the wound.

If the large wound to be vulcanized exceeds the effective length of

the vulcanization, the center should be vulcanized firstly then

both sides. The heated plates should overlap 15mm with the previous

position in re-vulcanization. The vulcanization shall be finished

within 40-50 minutes when the temperature rises to 135±5℃ and

pressure is 0.8-0.12MPa.

8. Check whether the repair is bound tightly or not, Flaw such as void, delaminating or sponge and so on are not allowed. As to new glue in heating area, aging, crack, under vulcanization and over vulcanization is not allowed. Inflating test shall be conducted if the repair is qualified.