QINGDAO SHUNHANG MARINE SUPPLIERS CO., LTD. |

|

Verified Suppliers

|

|

Anti High Pressure Anti Bursting Marine Rubber Airbags

Product Introduction:

History of Marine Rubber Airbags.

The airbags is invented in China in about 1986 by some experienced

engineers, to help launching small boats in rivers. After years of

development of technology, the airbags are adopted to launch huge

ship weigh up to 9000 tons or more.

Material: an airbag contains several layers of rubber-dipped Nylon

fabric+1 layer of rubber. For example,

7 layers of airbag, means 7 layers of rubber-dipped Nylon fabric +

1 layer of outer rubber.

Technical Requirement

According to CB/T 3795--1996, ship launching airbags should meet the following requirements.

1. Dimensional Deviation

Diameter & Effective Length Deviation: ±2%

Total Length Deviation: ±4%

2. Amount of Elastic Deformation: diameter deformation amount ≤ 5% under 1.2 times working pressure.

3. Safety Factor: >4.5

4. Air Tightness: depressurization < 5% after 1hour inflation

5. Surface Quality: fairing line shape, no crack, no bubble, no double skin, no impurities, no distinct dirt and other apparent defect.

6. end part anti-explosion design

Specifications of Our Marine Rubber Airbags:

| Some common sizes of our marine rubber airbags, customized sizes are also available | |||

| Diameter(m) | Effective Length(m) | Layer | Pressure(MPa) |

| 1.0 | 10 | 5~6 | 0.07~0.10 |

| 1.0 | 12 | 5~6 | 0.07~0.10 |

| 1.0 | 15 | 5~6 | 0.07~0.10 |

| 1.2 | 10 | 5~6 | 0.08~0.12 |

| 1.2 | 12 | 5~6 | 0.08~0.12 |

| 1.2 | 15 | 5~6 | 0.08~0.12 |

| 1.5 | 12 | 5~8 | 0.08~0.16 |

| 1.5 | 15 | 5~8 | 0.08~0.16 |

| 1.5 | 18 | 5~8 | 0.08~0.16 |

| 1.5 | 20 | 4~8 | 0.08~0.16 |

| 1.5 | 24 | 5~8 | 0.08~0.16 |

| 1.8 | 12 | 5~8 | 0.08~0.15 |

| 1.8 | 15 | 5~8 | 0.08~0.15 |

| 1.8 | 18 | 5~8 | 0.08~0.15 |

| 1.8 | 20 | 5~8 | 0.08~0.15 |

| 1.8 | 24 | 5~8 | 0.08~0.15 |

| 2.0 | 18 | 6~10 | 0.08~0.18 |

| 2.0 | 20 | 6~10 | 0.08~0.18 |

| 2.0 | 24 | 6~10 | 0.08~0.18 |

| 2.5 | 18 | 7~10 | 0.07~0.13 |

| 2.5 | 20 | 7~10 | 0.07~0.13 |

| 2.5 | 24 | 7~10 | 0.07~0.13 |

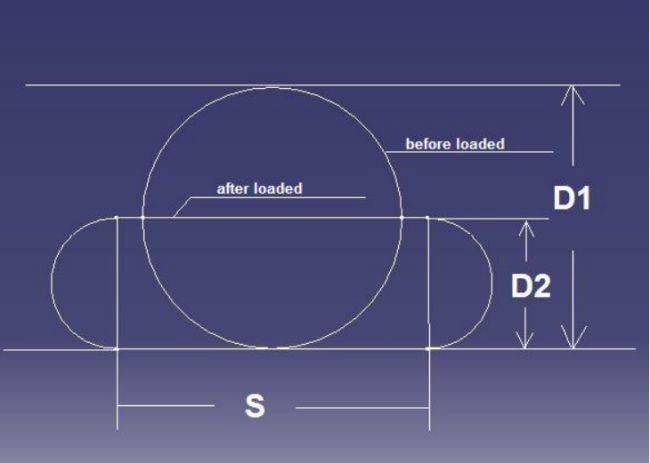

Caculation of Performance of Shunhang Marine Rubber Arbags

As a soft flexible body, airbag’s shape depends on various factors,

such as the shape of ship bottom, ramp shape, width of ship bottom,

length of airbag, position of airbag under the ship, etc.

Users should calculate the bearing capacity of airbags basing on

above factors, correct bearing capacity accordingly.

Formula: Bearing capacity F=PS

P=pressure in the airbag(MPa)

S=contacting area between ship bottom and airbag(M²)

S= π*(D1-D2)/2

Instruction of Application in Ship Launching

Airbag is more and more widely applied in ship launching project.

The application method is ceaselessly improved. The airbag

application application method for common medium ship launching

ship launching is as below,

1. Based on calculation result, enough rolling airbags and lifting

airbags, towing machines and air compressors are prepared. Before

using, airbags must be inflated and tested without loading(the

testing pressure must be no less than 1.25MPa). In case of air

leakage, the airbag must be prepared before using.

2. The way for ship movement, including the way from shipbuilding

berth to ramp, must be cleaned and flattened. Sundries must be

removed from the way, especially sharp iron nails and stones, to

avoid piercing the airbag. The ramp should be long enough and wide

in water.

3. All the protruding sharp corners and burrs on casting like ”A”

bracket and stern post must be polished to be smooth.

4. Fasten the hull with the steel cable of winch.

5. Close the sea chest valves of ship, fix the rudder and

propeller.

6. There are many ways to remove all blocks and fill in the rolling

airbags. Here we recommend two methods as below. User may choose

one basing on the equipment conditions such as ship weight, amount

of the airbags, etc.

(A)For light ship, the bearing capacity of the airbag is large

enough to lift the ship away form the blocks and therefore blocks

can be removed directly and fill in the airbags.

(B)For heavy ship, lifting airbags can be adopted to lift the

bottom of stern. Before lifting, firstly specify the optimum

position of the front-pivot and lifting airbags. According to the

figure as below,

the closer the front pivot to the center of gravity the better,

however, it will result in too many blocks around of the

front-pivot, which means a lot of workload to remove the blocks

manually. Therefore, the position shall be determined reasonably

considering such elements as ship length, etc. If possible, the

lifting airbags shall be located in the stern. However, the

location is also subject to line shape of the stern as the lift of

the lifting airbag will not be enough if the bottom is too high to

the ground. In this condition, it would be better move forward.

Therefore, the optimum position of the front-pivot and lifting

airbags shall be decided after specific calculations as the case

varies from ship to ship.

Q*Lq>W*Lw

In the formula,

Q=lift of the lifting airbag

W=weight of ship

Lq= the distance from the lift center of the lifting airbag to the

front-pivot

Lw=the distance from the center of gravity of the ship to the

front-pivot

7. Firstly, remove all the blocks in the lifting airbags and the

ones around the front-pivot. Then fill the lifting airbags and

start inflating until the bottom separates slightly from the

blocks. Remove blocks one by one from middle to the stern. Whenever

blocks of the section are removed, fill in the rolling airbags

immediately in the planned position and inflate it appropriately.

Followed by continuous block removing until all blocks in the stern

are completely removed and the rolling airbags are filled in.

8. Remove blocks from the middle of the ship to the front-pivot and

fill in all rolling airbags in the front by modifying pressure of

the airbags filled in the stern or similar methods as mentioned

above. Of sake of safety, add removed blocks in appropriate number

between the filled rolling airbags at any time. The blocks will not

be removed until the rolling airbags can support the weight of the

ship. Besides, when removed blocks of the same section, it shall be

started from middle to both sides. When remove the outermost block,

workers shall carry out the work outside the fender.

9. Adjust pressure in the airbags so that the bottom can be lowered

to appropriate working height. Make sure that the bottom will not

touch the ground while moving the ship. For average small-size

ship, the working height could be chosen within the arrange of

0.2m-0.3m.

10. All airbags shall be pointed at the center of the ship and

perpendicular to the launching direction.

11. Start the traction winch to release steel cable slowly followed

by slow movement of the ship. When the forefront airbags located in

the front part separates from the bottom, it shall be placed under

the stern immediately and fill in the airbags according to the

arrangement space of the airbags defined in the calculations.

12. Repeat the above process to move the ship to waterside slowly.

When the airbags can’t be filled in, block the river and forbid any

ships to pass.

13. Evacuate personnel in the dangerous zone, Inform staff on the

ship to get ready. When conditions such as water depth and so on

are enough, cut cable or unhook to shat the ship can launch

quickly. If the river is too narrow to realize quick launching,

release the cable slowly by traction winch to launch the ship

slowly.

14. For large ships, it is necessary to install anti-slip device.

15. Collect the airbags.

Attention During Application

1)Working pressure must be controlled strictly, it is not allowed

to exceed the working pressure.

2)No sharp and protruding hard object on the contacting surface of

the airbags, to avoid the puncture on the skin of airbags.

3)Avoid the distortion along the length of airbag.

4)Empty inflating test must be performed if the airbags were not

used for a long time or after reparation. The pressure should be as

same as the testing pressure of our company. Inspectors must be at

least 3 meters away from the airbags. For repaired airbag which was

damaged in large scale, its working pressure should be lowered

reasonably. Besides, annual check should be conducted on airbags

which are used frequently.

5)Don’t drag the airbags on the ground.

Storage of The Marine Rubber Airbags

1)If the airbags won’t be used for quite a long time, it shall be

washed and dried, filled with talcum powder inside and coated with

talcum powder outside, place it in dry, shady and ventilated place

in the warehouse.

2)Place string the airbags should be far away from the heat source.

3)The temperature of the warehouse should be kept no more than 30℃.

4)Keep the airbags away from acid, alkali, grease and organic

solvent.

5)The airbags should be stretched flat when not used. It is not

allowed to pile up and stack heavy object on the airbag.

Shunhang Marine Rubber Airbags