Longkou City Hongrun Packing Machinery Co., Ltd. |

|

150KW Foam Food Container Machine / Lunch Box Foam Board Production Line

1. PS foam sheet extrusion line

PS foam sheet extrusion line adopts Gentian type double-stage series high technology. The raw material is general polystyrene granule. In the extruding process, vesicant is injected at high pressure. After extruding, foaming, cooling, shaping and hauling off , it is winding to finished ps foam sheet rolls. This equipment adopts high speed non-stop hydraulic filter changer and OLC controller, it is easy for operation.

Machine Specifications

| Item | Unit | Parameter |

| Model | 105/120 | |

| Applicable materials | GPPS granule(123P/525) | |

| Thickness of sheet | mm | 1-3.5 |

| Width of sheet | mm | 540~1080 |

| Foaming rate | 12-20 | |

| Weight of product | kg/m³ | 50~83 |

| Output | kg/h | 150~200 |

| Rated power(approximately) | KW | 180 |

| Power supply | Three phase 380V/50Hz | |

| External dimension | mm | 24000×4100×2800 |

| Complete weight | Ton | About12 |

PS Foam Sheet Extruder Included Bellowed Equipment List:

A. Stainless steel Mixer and feeder

B. Φ105 Extruder

C. Φ120 Extruder

D. Screen changer

E. Die head

F. High pressure metering pump

G. Shaping, cutting and cooling unit

H. Haul-off unit

I. Electrostatic elimination system

J. Double position winder

K. Electric control system

2. PS foam food container forming machine

Fully automatic vacuum forming and cutting off integration machine is all-powerful thermoforming machine with integrating vacuum forming and cutting off at the same time. It can be used for processing all kinds of plastic sheet. This machine adopts computer digital forming system, PLC mechanical and electronic integration self-control and touch screen control working programme, it is easy to operate and has highly production efficiency.

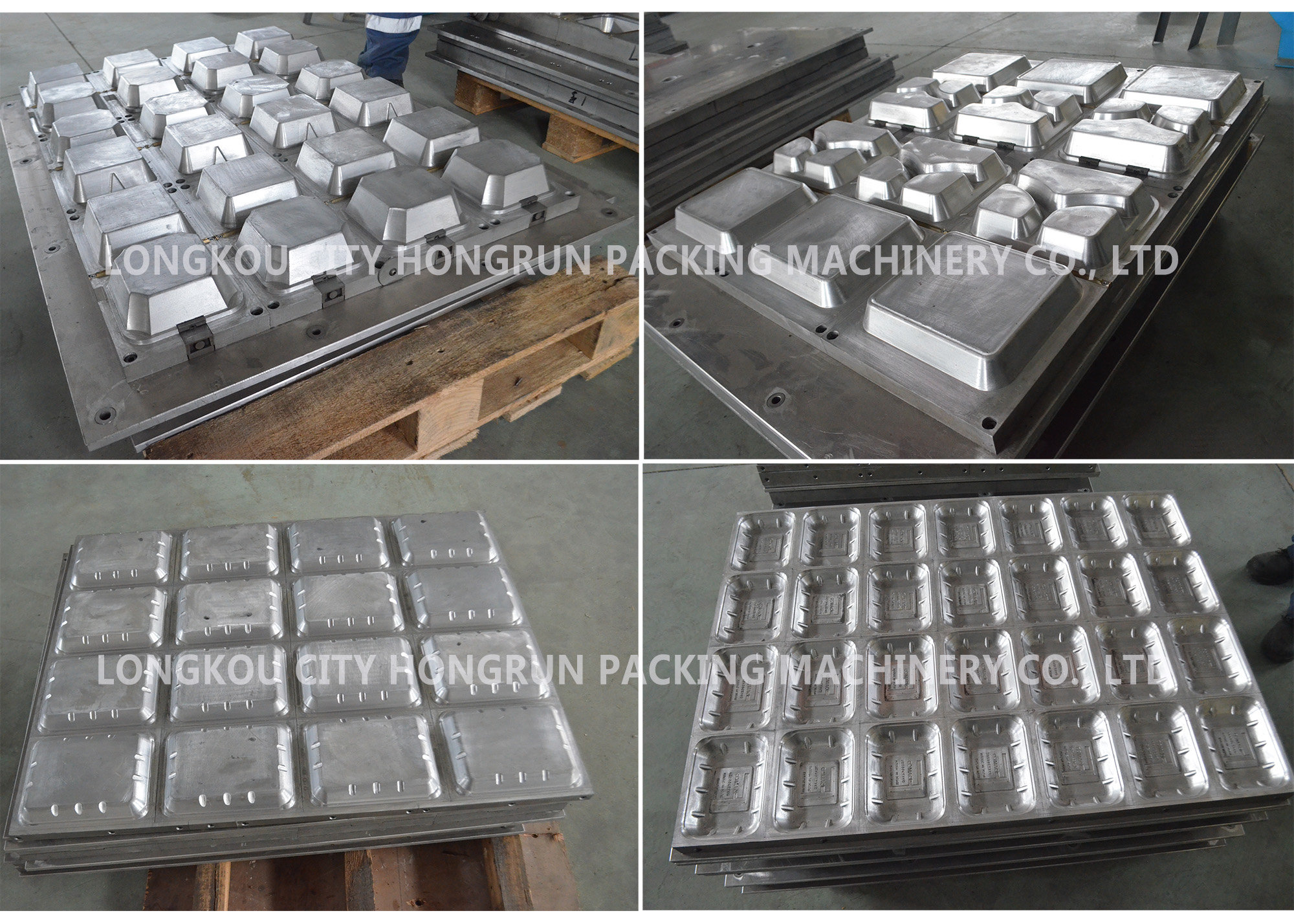

Forming mold

Main technical parameters

| Item | Unit | Parameter |

| Model | / | HR-M1080 |

| Power supply | / | Three phase 380V/50Hz |

| Production efficiency | s/mold | 4-5 |

| Installed power (approximately) | KW | 168 |

| Total weight (approximately) | Ton | 16 |

| Mounting size | m | 12×2×2.6 |

| Compressed air capacity | m3/min | 0.4~0.7 |

| Compressed air pressure | Mpa | 0.7 |

| Cooling water | T/h | 1 |

Automatic Vacuum Forming Machine Included Bellowed Equipment List:

A. Unwinding unit

B. Heating unit

C. Vacuum forming unit

D. Truncation unit

E. Auto stacking unit

F. Collecting products unit

G. Leftover material rewinding device

H. Heating electric control cabinet

I. Operating electrical cabinet

3. Recycling machine

This machine can process PS material and it is mainly used to recycle the high foam polystyrene and high foam polystyrene products.It is the ideal equipment to recycle waste material.

Final products: