CEBE GROUP HK CO.,LTD |

|

Verified Suppliers

|

|

Oil injected rotary screw compressors

GA 90+-315+(VSD+)

GA 200-250 HYBRID+

Highest reliability,lowest operating costs

The shortest route to maximize your profitability is to minimize your operational costs. With up to 80% of a compressor lifecycle cost coming from the energy it consumes, this should be a clear focus.Atlas Copco's GA+ compressors with SmartInjection enabled compression elements and IE4/IE5 or better class motors are designed to achieve significant energy savings whileproviding long and trouble-free life even in the harshest environmental conditions.

Advantage:

· Efficiency

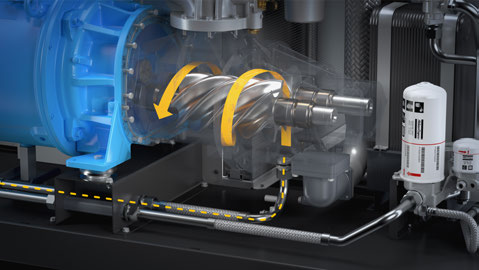

At the heart of the GA+ compressors are state-of-the-art

compression elements with Smartlnjection technology and high

efficiency oil cooled lE4/IE5 or better class motors.This highly

efficient drive train coupled with generous cooling capacity, low

internal pressure drops and precise control from the

ElektronikonTouch ensures optimum efficiency.

· Reliability

The GA+ compressor's drive train is lP66 rated protecting it

completely from environmental dust and moisture ensuring it can

operate reliably in the toughest conditionsand at ambient

temperatures up to 55°℃/131°F.

· Easy maintenance

All parts that require regular maintenance are fully considered for

the convenience of operation, which greatly reduces the time

required for maintenance. The unique design of the box board makes

all the components within the unit within easy reach. At the same

time, each component is designed with full consideration of its

maintainability, and the average maintenance time is reduced by

more than half compared with traditional designs.

Applications in all walks of life

1.General industry

Lower life cycle costs

Compressed air is essential in daily industrial production, and its

application fields include: pneumatic tools for cutting, drilling,

hammering and grinding processes; Pneumatic actuators and valves;

Ventilation system; Packaging and stacking equipment and conveyor

systems. The GA + series is designed for lower life cycle costs.

2.Mining

Adapt to harsh conditions

Compressed air is essential for the mining industry, including:

dust bag filtration, maintenance gas, ventilation gas and pneumatic

tools. The Ga + series air compressors are not only reliable, but

also durable, even in harsh environments.

3.Power plant

Stable and reliable

To ensure an uninterrupted supply of energy, power plants must

operate day and night. Therefore, a continuous supply of compressed

air is essential for trouble-free operation of power plants. The GA

+ series compressors provide reliable compression air for silt

purging and fly ash treatment.

4.Metal smelting

Lower energy efficiency

A large amount of compressed air is used in the process of

instrument gas and pneumatic transportation of raw materials in

metal smelting plants, so effective solutions are needed to reduce

operating costs. The Atlas Copco ga + series of compressors

significantly reduce customers' operating costs thanks to their

high energy efficiency.

5.Cement industry

Easy to maintain and maintain

Cement plants require a large amount of compressed air, which is

mainly used for the transportation of raw materials. In cement

plants, large amounts of dust and water vapor inevitably damage

compressor performance, resulting in additional energy and

maintenance costs. The GA + series compactor not only has the

transmission system with IP66 protection level to avoid pollutants

entering the compactor; And easy to maintain, such as card-type

design of the oil core, pull-type design of the cooler and so on.

Efficiency(combining the best of both worlds)

- Variable Speed Drive (VSD)

Over 80% of a compressor's lifecycle cost is taken up by the energy

it consumes. Moreover,the generation of compressed air can account

for more than 40% of a plant's total electricity bill.To cut your

energy costs, Atlas Copco pioneered Variable Speed Drive(VSD)

technology in the compressed air industry. VSD leads to major

energy savings, while protecting the environment for future

generations.Thanks to continual investments in this

technology,Atlas Copco offers the widest range of integrated VSD

compressors on the market.

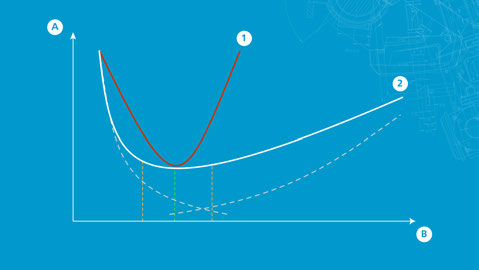

Legend

A= Losses

B= Speed

1=Total losses traditional element

2 =Total losses AC element

- VSD savings

Atlas Copco's VSD technology closely follows the air demand by

automatically adjusting the motor speed.This results in large

energy savings of up to 35%6.The Life Cycle Cost of a compressor

can be cut by an average of 22%. In addition, lowered system

pressure with VSD minimizes energy use across your production

dramatically.

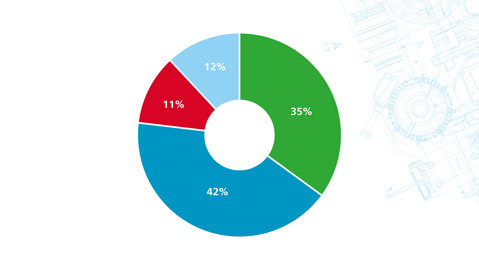

Legend

42%= Energy

35%= Energy savings with VSD

12%= lnvestment

11%= Maintenance

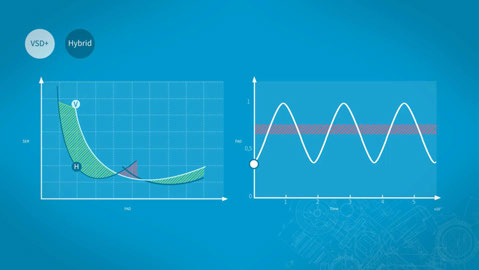

- The Hybrid Principle

Atlas Copco innovatively integrates the fixed frequency module and the frequency conversion module into a hybrid motor, which matches our intelligent control system to more accurately match the customer's gas needs.

- The Hybrid Benefits

Our hybrid compressor includes two drive trains. One variablespeed

and a fixed speed drive.This brings many benefits such as:

· Smaller footprint compared to having two smaller units

· Higher turndown compared to a VSD compressor

· Lower energy consumption

· Independent Single Core Operation

- Higher Flexibilty

By having two cores and controllers,the customer can chose to run a

single core if required, or if one core is not operational.This

also means the back up compressor can be sized smaller.

- Dual set-point and automatic stop

Most production processes create fluctuating levels of demand

which, in turn, can create energy waste in low use periods. Using

the ElektronikonRunit controller, you can manually or automatically

switch between two different setpoints to optimize energy use and

reduce costs at low use times.

In addition, the controller is also integrated with Atlas Copco's unique control algorithm, in the premise of avoiding frequent start and stop motors, as far as possible to shorten the unloading operation time and further reduce operating costs.

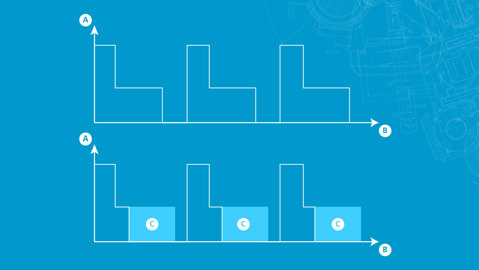

Legend

A = Power consumption

B = Time

C = Energy Saving

- Components designed for efficiency

· SmartInjection provides exact amount of oil required to element

ensuring it always works at peak efficiency.

· High efficiency IE4(Fixed Speed) and lE5 (VSD+) motor.

· lntegrated energy recovery system recovers up to 78% of energy

from integrated motor and element oil circuit.

· Dual speed or VSD fan for energy efficiency in lower temperatures.

- Elektronikon Mk5 touch

The Elektronikon unit controller is specially designed to maximize

the performance of your compressors and air treatment equipment

under a variety of conditions.Our solutions provide you with key

benefits such as increased energy efficiency, lower energy

consumption, reduced maintenance times and less stress...

lessstress for both you and your entire air system.

- Optimizer 4.0

· Minimizing Excess Pressure

Optimizer 4.0 minimizes the generation of excess compressed air by

starting and stopping compressors. Its user friendly interface

enables you to set multiple pressure bands, allowing you to

optimize your compressor installation for varying

circumstances,such as non-productive hours.

· Full VSD Benefits

With Optimizer 4.0 you can realize the full energy saving potential

of VSD (variable Speed Drive).lt regulates the VSD to ensure that

the compressed air output is proportional to the demand, preventing

higher pressures than required, excess unloaded running,and

spiraling energy costs.

· lmproving Uptime

Optimizer 4.0 effectively eliminates production downtime caused by

unexpected system pressure drops, because it regulates the system

pressure instead of the compressor output pressure.

This means Optimizer 4.0 will automatically adjust the system

pressure to compensate for pressure drops due to filters, piping

and dryers for example.

we also provide additional functionality and services on Optimizer

4.0 to ensure that your energy savings will stand the test of

time.Even when your installation needs adaptations or your

demandchanges.

Customized to your needs (A range of optional features are available to ensure the GA compressor is customized to the applications requirements)

- High ambient temperature variant

Reliable and continuous operation of the compressor in hotand humid

environments up to :

· max. 55C ( 131F ) for fixed speed pack

· max. 50°C ( 121°F ) for vSD pack

- Shock pulse monitoring

Continuous SPM "Shock Pulse Measurement” monitoring system of the

compressor element & motor bearings.The sensors are connected

to the ElektronikonR which is showing the individual vibration

levels.

Alarm and/or shutdown levels can be programmed during commissioning

of the compressor. With this monitoring system, the compressor can

run longer, since overhaul can be done when needed and preventive

maintenance can be organized.

- Energy recovery

The energy recovery system consists of a build-in stainless steel

heat exchanger and thermostatic controlled system to recover the

heat from the compressor in the form of warmwater or hot water

without any adverse influence on thecompressor performance.

Technical specifications:

GA90+-315+(VSD+)和GA200-250 HYBRID+-50HZ

| Type | Maximum working pressure | Capacity FAD | Install motor power | Outlet | Weight | |||||

| Standard | Full Feature | Standard | Full Feature | Standard | Full Feature | |||||

| Air cooling(kg) | Water cooling(kg) | Air cooling(kg) | Water cooling(kg) | |||||||

| bar(e) | bar(e | l/s | m*/min | kw | ||||||

| GA90+-5.5 | 5.5 | 5.3 | 355 | 21.3 | 90 | G3" | 2721 | 2721 | 2971 | 3001 |

| GA90+-7.5 | 7.5 | 7.3 | 297 | 17.8 | 90 | G3" | 2721 | 2721 | 2971 | 3001 |

| GA90+-8.5 | 8.5 | 8.3 | 283 | 17.0 | 90 | G3" | 2721 | 2721 | 2971 | 3001 |

| GA90+-10 | 10 | 9.8 | 258 | 15.5 | 90 | G3" | 2721 | 2721 | 2971 | 3001 |

| GA110+-5.5 | 5.5 | 5.3 | 425 | 25.5 | 110 | G3" | 2802 | 2852 | 3052 | 3082 |

| GA110+-7.5 | 7.5 | 7.3 | 370 | 22.2 | 110 | G3" | 2802 | 2852 | 3052 | 3082 |

| GA110+-8.5 | 8.5 | 8.3 | 347 | 20.8 | 110 | G3" | 2802 | 2852 | 3052 | 3082 |

| GA110+-10 | 10 | 9.8 | 315 | 18.9 | 110 | G3" | 2802 | 2852 | 3052 | 3082 |

| GA132+-5.5 | 5.5 | 5.3 | 503 | 302 | 132 | G3" | 2885 | 2985 | 3135 | 3215 |

| GA132+-7.5 | 7.5 | 7.3 | 442 | 26.5 | 132 | G3" | 2885 | 2985 | 3135 | 3215 |

| GA132+-8.5 | 8.5 | 8.3 | 417 | 25.0 | 132 | G3" | 2885 | 2985 | 3135 | 3215 |

| GA132+-10 | 10 | 9.8 | 382 | 22.9 | 132 | G3" | 2885 | 2985 | 3135 | 3215 |

| GA160+-7.5 | 7.5 | 7.3 | 527 | 31.6 | 160 | G3" | 2963 | 3063 | 3213 | 3293 |

| GA160+-8.5 | 8.5 | 8.3 | 500 | 30.0 | 160 | G3" | 2963 | 3063 | 3213 | 3293 |

| GA160+-10 | 10 | 9.8 | 458 | 27.5 | 160 | G3" | 2963 | 3063 | 3213 | 3293 |

| GA180+-5.5 | 5.5 | 5.3 | 692 | 41.5 | 180 | DN100 | 5741 | 5122 | 6330 | 5731 |

| GA180+-7.5 | 7.5 | 7.3 | 585 | 35.1 | 180 | DN100 | 5741 | 5122 | 6330 | 5731 |

| GA180+-8.5 | 8.5 | 8.3 | 557 | 33.4 | 180 | DN100 | 5741 | 5122 | 6330 | 5731 |

| GA180+-10 | 10 | 9.8 | 502 | 30.1 | 180 | DN100 | 5741 | 5122 | 6330 | 5731 |

| GA200+-5.5 | 5.5 | 5.3 | 835 | 50.1 | 220 | DN100 | 5902 | 5284 | 6541 | 5943 |

| GA200+-7.5 | 7.5 | 7.3 | 732 | 43.9 | 220 | DN100 | 5902 | 5284 | 6541 | 5943 |

| GA200+-8.5 | 8.5 | 8.3 | 685 | 41.1 | 220 | DN100 | 5902 | 5284 | 6541 | 5943 |

| GA200+-10 | 10 | 9.8 | 618 | 37.1 | 220 | DN100 | 5902 | 5284 | 6541 | 5943 |

| GA250+-5.5 | 5.5 | 5.3 | 987 | 59.2 | 264 | DN100 | 6064 | 5446 | 6703 | 6105 |

| GA250+-7.5 | 7.5 | 7.3 | 870 | 52.2 | 264 | DN100 | 6064 | 5446 | 6703 | 6105 |

| GA250+-8.5 | 8.5 | 8.3 | 833 | 50.0 | 264 | DN100 | 6064 | 5446 | 6703 | 6105 |

| GA250+-10 | 10 | 9.8 | 750 | 45.0 | 264 | DN100 | 6064 | 5446 | 6703 | 6105 |

| GA315+-7.5 | 7.5 | 7.3 | 1037 | 622 | 320 | DN100 | 6220 | 5602 | 6859 | 6261 |

| GA315+-8.5 | 8.5 | 8.3 | 1000 | 60.0 | 320 | DN100 | 6220 | 5602 | 6859 | 6261 |

| GA315+-10 | 10 | 9.8 | 907 | 54.4 | 320 | DN100 | 6220 | 5602 | 6859 | 6261 |

| GA110VSD++-8.5 | 8.5 | 8.3 | 96-393 | 5.8-23.6 | 110 | G3" | 2300 | 2351 | 2550 | 2581 |

| GA110VSD++-10 | 10 | 9.8 | 96-325 | 5.8-19.5 | 110 | G3" | 2300 | 2351 | 2550 | 2581 |

| GA132VSD+-8.5 | 8.5 | 8.3 | 96-468 | 5.8-28.1 | 132 | G3" | 2416 | 2516 | 2666 | 2746 |

| GA132VSD+-10 | 10 | 9.8 | 96-392 | 5.8-23.5 | 132 | G3" | 2416 | 2516 | 2666 | 2746 |

| GA160VSD+-8.5 | 8.5 | 8.3 | 96-557 | 5.8-33.4 | 160 | G3" | 2450 | 2550 | 2700 | 2780 |

| GA160VSD+-10 | 10 | 9.8 | 96-472 | 5.8-28.3 | 160 | G3" | 2450 | 2550 | 2700 | 2780 |

| GA200VSD+-8.5 | 8.5 | 8.3 | 193-774 | 11.5-46.4 | 220 | DN100 | 5093 | 4475 | 5732 | 5134 |

| GA200VSD+-10 | 10 | 9.8 | 193-638 | 11.5-383 | 220 | DN100 | 5093 | 4475 | 5682 | 5234 |

| GA250VSD+-8.5 | 8.5 | 8.3 | 193-919 | 11.5-55.1 | 264 | DN100 | 5194 | 4576 | 5832 | 5303 |

| GA250VSD+-10 | 10 | 9.8 | 193-767 | 11.5-46.0 | 264 | DN100 | 5194 | 4576 | 5783 | 5084 |

| GA315VSD+-8.5 | 8.5 | 8.3 | 193-1092 | 11.5-65.5 | 320 | DN100 | 5263 | 4645 | 5901 | 5185 |

| GA315VSD+-10 | 10 | 9.8 | 193-924 | 11.5-55.4 | 320 | DN100 | 5263 | 4645 | 5901 | 5303 |

| GA 200 HYBRID+-7.5 | 7.5 | 7.3 | 96-755 | 5.8-45.3 | 222 | DN100 | 5467 | 4849 | 6105 | 5507 |

| GA 200 HYBRID+-8.5 | 8.5 | 8.3 | 96-715 | 5.8-42.9 | 222 | DN100 | 5467 | 4849 | 6105 | 5507 |

| GA 200 HYBRID+-10 | 10 | 9.8 | 96-640 | 5.8-38.4 | 222 | DN100 | 5467 | 4849 | 6056 | 5458 |

| GA 250 HYBRID+-7.5 | 7.5 | 7.3 | 96-915 | 5.8-54.9 | 270 | DN100 | 5583 | 4964 | 6221 | 5622 |

| GA 250 HYBRID+-8.5 | 8.5 | 8.3 | 96-861 | 5.8-51.7 | 270 | DN100 | 5583 | 4964 | 6221 | 5622 |

| GA 250 HYBRID+-10 | 10 | 9.8 | 96-776 | 5.8-46.6 | 270 | DN100 | 5583 | 4964 | 6172 | 5573 |

Dimensions:

| Type | L | W | H | |||

| mm | inch | mm | inch | mm | inch | |

| GA 90+-160+(VSD+) | 2500 | 98.5 | 1785 | 70.3 | 2020 | 79.5 |

| GA 90+-160+(VSD+) FF | 2900 | 114.2 | 1785 | 70.3 | 2020 | 79.5 |

| GA 180+-315+(VSD+) (HYBRID+)(Air cooled) | 4390 | 173 | 2090 | 82.3 | 2020 | 79.5 |

| GA 180+-315+(VSD+) (HYBRID+) FF(Air cooled) | 5020 | 198 | 2090 | 82.3 | 2020 | 79.5 |

| GA 180+-315+(VSD+) (HYBRID+)(Water cooled) | 3760 | 148 | 2090 | 82.3 | 2020 | 79.5 |

| GA 180+-315+(VSD+) (HYBRID+) FF(Water cooled) | 4390 | 173 | 2090 | 82.3 | 2020 | 79.5 |