Kinte Materials Science and Technology Co.,Ltd |

|

Verified Suppliers

|

|

Thermoset Epoxy Resin Powder Coating, FBE Powder Coating with Excellent High Temperature Resistance

◎Introduction

KT-621M02 is a thermosetting epoxy powder coating that is engineered to protect pipes from corrosion in harsh working environments. KT-621M02 is designed for anti-corrision in high temperature environment. It can be used in single layer, double layer or the prime layer of 3PP.

The product has excellent high temperature resistance, excellent acid and alkali resistance, and good adhesion to the substrate. The coating will not fall off when immersed in hot water below 80℃ for a long time, and can be used for anti-corrosion of the inner wall of hot water pipelines.

◎Product Features

Excellent high temperature resistance

Excellent acid and alkali resistance

Excellent anti-corrosion properties

Good adhesion to the substrate

For anti-corrosion of the inner wall of hot water pipelines

For anti-corrision in high temperature environment

◎Powder Properties

| Items | Acceptance Criteria | Test Standard | |

| Color | Green, Blue, Red, etc. | Visual inspection | |

| Moisture Content (%) | <0.5% | GB/T6554 | |

| Density (g/cm3) | 1.40-1.60 | GB/T4472 | |

| Thermal Properties | Tg2 | >120℃ | SY/T0315 |

| ΔH | 40±10J/g | ||

| Gel Time (200℃ s) | ≤120 | GB/T6554 | |

| Cure Time (200℃, min) | ≤40min | SY/T0315 | |

◎Film Properties

| Items | Acceptance Criteria | Test Standard | |

| Cathodic Disbondment | 48 Hours, -1.5 volt, 85℃ | ≤5.0mm | SY/T0315 |

| Adhesion | 95℃, 48h | Grade 1-2 | SY/T0315 |

| Hot water Resistance | 1000h, 95℃ | Grade 1-3 | SY/T0315 |

| Impact Resistance | 1.5J@-30℃ | No cracks | SY/T0315 |

| Flexibility | 2° Bend @0℃ | No cracks | SY/T0315 |

| Hardness | Shore hardness | >80 | ISO868:2003 |

| Cure Degree | ΔTg, ℃ | ΔTg≤5 | SY/T0315 |

| High Temperature and High Pressure Resistance★ (with primer) | 148℃, 70MPa, N2 pressurized, liquid phase: PH12.5 sodium hydroxide aqueous solution, the sample is completely immersed | The film does not blister, peel off, and does not degrade adhesion | SY/T6717 |

Note:

1. All data in sheet 1 and sheet 2 are based on laboratory tests and practical experience.

2. It is recommended that the product should pass the process evaluation before batch use to avoid unnecessary losses to customers due to various reasons such as process.

3 "★" This property can only be satisfied with primer.

◎Coating Process

1) Remove oil, rust and other loose deposits, moisture, etc. on the surface.

2) Sand blasting or shot blasting to Sa2.5 level, anchor pattern depth 60⁓100μm, dust removal on the surface to near white level, pay attention to adding new and old sand evenly to make the ratio stable.

3) Thoroughly clean the surface of the pipe.

4) The special primer for spraying is required to be sprayed evenly and the spray thickness is below 25μm. Note that the thickness of the primer should not overwhelm the depth of the anchor pattern. (Note: This process is a recommended process. If conditions permit, you can spray primer, and the anti-corrosion effect is better)

5) Preheating, put the pipes sprayed with primer into the heating furnace to preheat, generally controlled at 175⁓190℃.

6) Coat the powder coating on the inner surface of the pipe with a thickness of more than 250μm.

7) Put the sprayed steel pipe into the heating furnace and cure at 200±10℃ for 20-40 minutes (according to the gel time) to make the coating reach the best state.

8) Test the coating performance after the coating is naturally cooled.

◎Storage

1. The product should be stored in a cool, ventilated, dry room with a temperature below 25°C and a humidity below 60%.

2. Keep away from fire and heat insulation.

3. The package can be opened at any time, and it should be sealed in time after use to prevent the powder from being polluted and damp.

4. Minimize the number of movements and avoid impact and pressure.

5. The stable storage period is 12 months.

Note: Improper storage conditions can easily cause the epoxy powder product to deteriorate, agglomerate and become unusable.

◎Package and Transportation

This product is a non-hazardous item. Packed in carton, 25kg per carton, the carton is lined with polyethylene plastic bag. During the shipping process, it should be lightly loaded, lightly unloaded and protected from direct sunlight, heat and moisture.

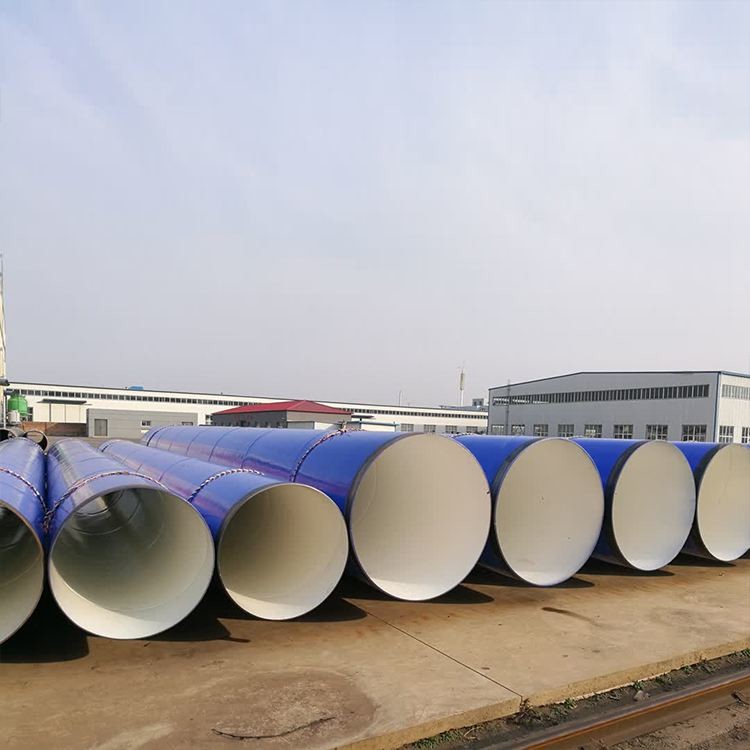

◎Product Show