Kinte Materials Science and Technology Co.,Ltd |

|

Verified Suppliers

|

|

Anti Scratch Colorful Powder Coating for Coil Steel, Special Use Thermoset Powder Coating

◎ Introduction

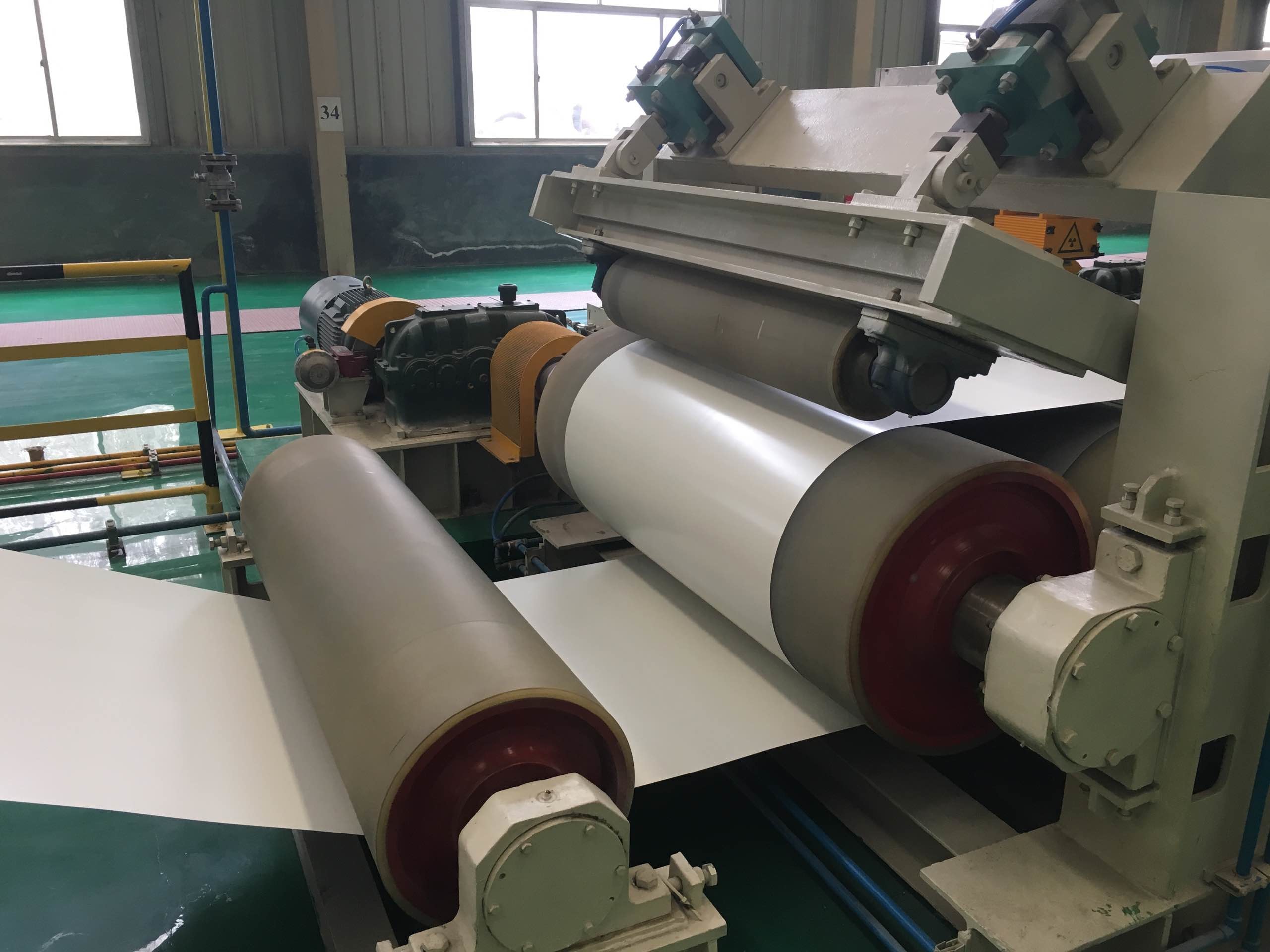

Coil coating is a kind of professional coating used to coat the surface of the steel plates and aluminum plates and make a pre-coated coil. It has changed the traditional method of coating metal sheets after forming and processing. Instead, the coil coating is pre-painted on the metal coil to form a color-coated steel plate for processing and is widely used in building materials, home appliances, and other fields. This "pre-coating" coating process has the advantages of simplifying the production process, improving construction efficiency, saving investment and transportation costs, and having better performance than the traditional "post-coating" process, which is one of the future development trends of the coatings industry.

To date, almost all pre-coated coils have been painted using liquid coil coatings. However, traditional liquid coil coatings contain organic solvents (VOCs) that are harmful to the environment. The powder coating does not contain any organic solvent and is a powdery substance with the advantage of zero VOC emission, and is one of the best choices to replace traditional liquid coil coatings.

In addition, as countries pay more and more attention to environmental protection, coating manufacturers are forced to develop products and technologies that can replace traditional liquid coil coatings. The main technical bottleneck of coil powder coatings lies in rapid coating and rapid curing. The former involves coating equipment and processes, while the latter involves the formulation and curing methods of powder coatings.

The powder coating for high-speed spraying of coil steel independently developed by our company for five years was successfully applied in a steel plate Co., Ltd. in Shandong, creating the technology of high-speed continuous spraying of powder coating for pre-coated steel plate. The coating speed reaches 60-120 m/min, surpassing the 40m/min production speed of similar powder coating units in Europe and the United States, reaching the international advanced level.

This product adopts a number of innovative technologies to solve a series of technical problems such as rapid curing of powder coatings (60-120m/mins), fast and efficient powdering, and high-speed production. Not only achieves the rapid spraying process of powder coatings at a line speed of 80m/min for the first time in China but also realizes the characteristics of good coverage, good leveling, and excellent performance under the condition of thin coating (20um-40um) of powder coatings. The product performance not only meets the technical standards of the coil industry, but also is superior to the current paint coating performance in key performances such as low-temperature bending, acid and alkali resistance, hardness, MEK resistance, edge cover, and aging resistance.

◎ Key Features

Coil color coating special powder coating has the characteristics of simple construction, strong decoration, one-time spraying, etc. Compared with solvent-based coatings, it has high utilization rate, is not easy to scratch, is environmentally friendly, has no VOC emissions, saves energy, and has excellent overall coating performance.

1. The coating is beautiful, with good texture and scratch resistance, and the thickness of one spray can reach 25-80 μm.

2. Excellent post-processing properties such as T-bend and impact resistance.

3. Excellent acid and alkali resistance, boiling resistance and MEK resistance.

4. Good aging resistance, corrosion resistance, humidity and heat resistance.

◎ Application Field

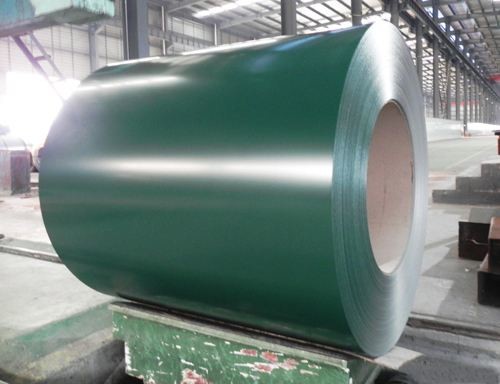

1. This product can be used for coiled steel and coiled aluminum color-coated panels. Because of its convenient installation, high strength, easy cleaning, and impact resistance, it is widely used in workshops, prefabricated houses, residential prefabricated components, roofs, ceiling curtain walls, containers, Isolation fences, household appliances, furniture, containers, door frames, etc.

2. 30m/min-120m/min coil steel color-coated plate powder coating can be designed according to requirements.

3. Powder coatings with different effects such as leveling, wrinkle, orange pattern, sand pattern, snow pattern and silver powder can be designed according to appearance requirements.

◎ Properties Index

| Properties | Test Method | Test Result |

| Appearance | Eyeballing | Smooth and flat |

| Coating Process | / | One coat and one bake |

| Film Thickness | GB/T 13452.2-2008 | 25μm-80μm |

| Pencil Hardness | GB/T13448-2019 | 3H |

| Scratch Resistance Test | GB/T13448-2019 | 2800g |

| Reverse Shock | GB/T13448-2019 | ≥ 9J |

| Cupping Test | GB/T13448-2019 | 8mm |

| MEK | GB/T13448-2019 | ≥ 120 times |

| T-bend Test | GB/T13448-2019 | 0T good |

| Acid Resistant | GB/T13448-2019 | 5% HCl, soaked for 240h without foaming or falling off |

| Alkali Resistant | GB/T13448-2019 | 5% NaOH, soaked for 168h without foaming or falling off |

| Humid and Heat Resistant | GB/T1740-2019 | 1000h coating no peeling, no blistering, no discoloration |

| Dry Heat Resistance Test | GB/T13448-2019 | After baking at a constant temperature of 170°C for 1.5 hours, the color difference of white color is less than 0.5, and red and blue color is less than 0.3. |

| Boiling Tesistance | GB/T13448-2019 | 4h no shedding, no foaming, no chalking |

| Cold Shock Resistance | / | -18°C for 24h, 0T is good, impact is good |

| Aging Resistance | / | Bake at 100°C for one hour, the T-bend does not rise |

| Resistant to Artificial Aging | GB/T1865-2019 | 1000h xenon lamp aging, no powdering, no shedding, 80% gloss retention |

| Salt Spray Resistance Test | GB/T1171-2019 | ≥ 500h |

◎Transportation and Storage

Carton packaging, net weight 20 or 25kg.

Non-dangerous goods, no special transportation requirements.

Store in a cool, dry place below 30°C.

Shelf Life: 12 months.

◎Application Examples