Runsheng Packing Industry Co.,Ltd |

|

Verified Suppliers

|

|

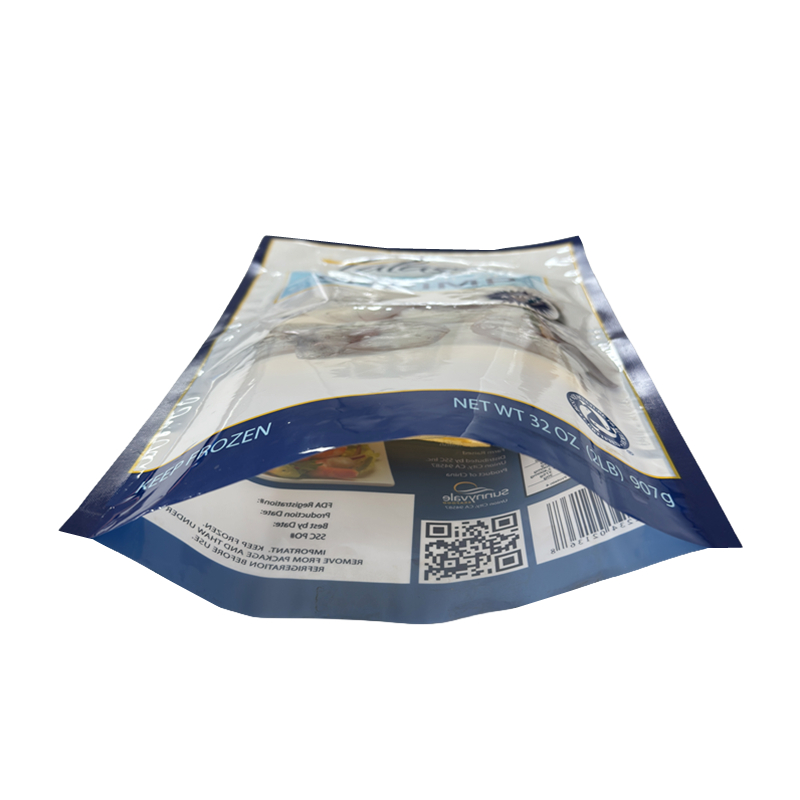

HS code | 3923210000 |

Size | Customized Size

|

Material | PET/PE(polyethylene) |

Color | Gravure printing with Max 9 colors |

Applicable Range | Frozen food |

The production process of food plastic bags usually includes the

following steps:

1. Material preparation: Choose plastic materials that meet food

safety standards as raw materials for food plastic bags, such as

polyethylene (PE), polypropylene (PP), polyethylene vinyl acetate

copolymer (EVA), etc. These materials need to be inspected and

screened to ensure their quality and compliance with relevant

regulatory requirements.

2. Printing design: Carry out printing design for food plastic bags

according to customer requirements and product needs. This includes

choosing the appropriate printing method (such as flexographic

printing, letterpress printing, etc.) and colors, as well as

printed patterns, text, brand logos, etc.

3. Bag making and forming: After the prepared plastic sheet is

printed, it enters the bag making and forming process. This step

usually includes operations such as cutting, folding, heat sealing

and crimping. Through heat sealing technology, the edges of the

plastic sheet are heated and pressed together to form the bottom

and sides of the bag.

4. Plastic bag processing: further processing and processing of the

prepared food plastic bags as needed.

This may include adding functional touches such as zipper seals,

bottom closures, opening designs, and

more.

5. Inspection and packaging: Conduct quality inspection on the

prepared food plastic bags to ensure that they meet relevant

standards and requirements. Afterwards, the plastic bags are packed

and packaged in preparation for shipment.