SHANGHAI ROYAL TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Stainless Steel Screws Jet Black Coating Equipment , MF Sputtering

Thin Film Deposition Machine, Graphite PVD Coating

PVD plating in Metal screw industry application

Physical Vapor Deposition (PVD) decorative hard coatings in the

home appliances & electronics made of

stainless steel material has been used widely for decades. It gives

an attractive colors and high wear resistance for our luxury

consumer goods such as: watch components, wring instruments or

spectacles. Some manufactures want to maintain both the high wear

resistance of PVD and the high reflective finishing surface which

provides the product with a high quality image.

RTAC-SP black thin film coating equipment can produce highly

reflective deep black films specifically for high quality aesthetic

demand.

Jet black thin film coating plant advantages

Robust design, large batches, fast cycle, flexible coating

processes are the basic design concepts of Royal Team.

Technical Specifications

| MODEL | RTAS1600 | ||||||

| TECHNOLOGY | Magnetron Sputtering (DC or MF) + Ion Plating | ||||||

| MATERIAL | Stainless Steel (S304) | ||||||

| CHAMBER SIZE | Φ1600*H1250mm | ||||||

| CHAMBER TYPE | Cylinder, vertical, 1-door | ||||||

| SPUTTERING SYSTEM | Exclusively design for thin black film deposition | ||||||

| DEPOSITION MATERIAL | Aluminum, Silver, Copper, Chrome, Stainless Steel, Nickel, Titanium | ||||||

| DEPOSITION SOURCE | 2 Cylindrical Sputtering Targets + 7 Steered Cathodic Arc Sources | ||||||

| GAS | MFC- 4 ways, Ar, N2, O2, C2H2 | ||||||

| CONTROL | PLC(Programmable Logic Controller) + Touch Screen | ||||||

| PUMP SYSTEM | SV300B - 2 sets (Leybold) | ||||||

| WAU2001 - 1 sets (Leybold) | |||||||

| D60T- 2sets (Leybold) | |||||||

| Turbo Molecular Pumps: 3* F-400/3500 | |||||||

| PRE-TREATMENT | Bias power supply: 1*36 KW | ||||||

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment | ||||||

| COOLING | Cold Water | ||||||

| POWER ELECTRICAL | 480V/3 phases/60HZ ( USA compliant) | ||||||

| 460V/3 phases/50HZ ( Asia compliant) | |||||||

| 380V/3 phases/50HZ ( EU-CE compliant) | |||||||

| FOOTPRINT | L3000*W3000*H2000mm | ||||||

| TOTAL WEIGHT | 7.0 T | ||||||

| FOOTPRINT | ( L*W*H) 5000*4000 *4000 MM | ||||||

| CYCLE TIME | 30~40 minutes (depending on substrate material, substrate geometry and environmental conditions) | ||||||

| POWER MAX.. | 155KW | ||||||

| AVERAGE POWER CONSUMPTION (APPROX.) | 75KW |

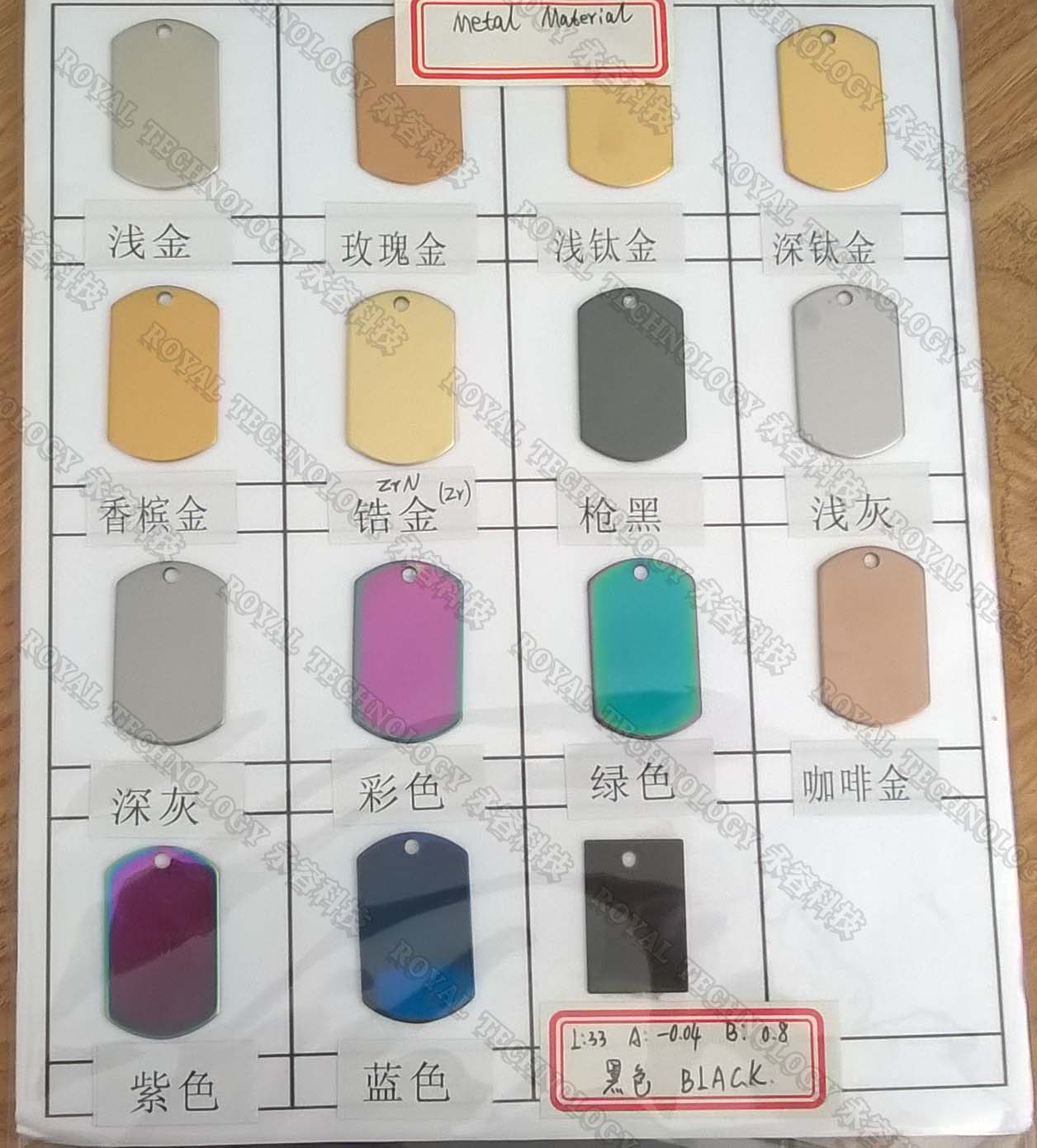

MF sputtering + Multi arc coater coating decorative colors:

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.