Zhejiang Tianyang Rotational Technology Co.,Ltd. |

|

Verified Suppliers

|

|

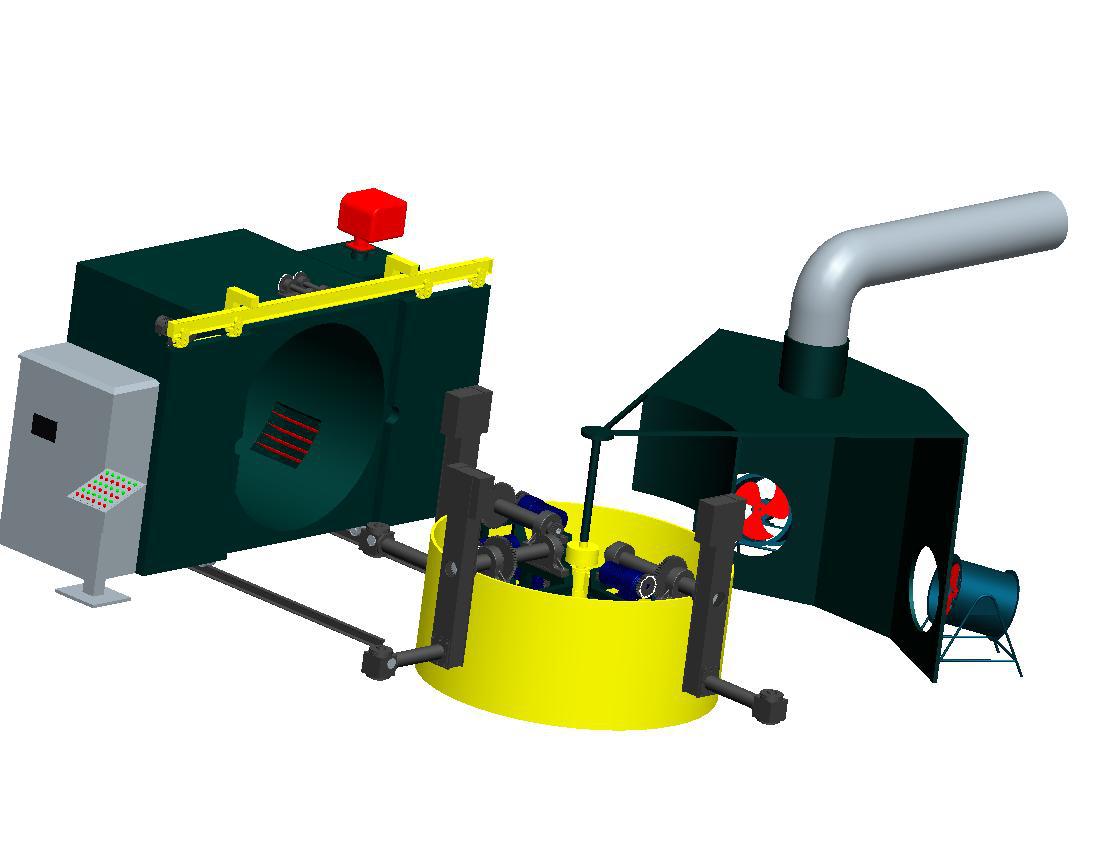

500-1000 Liters Capacity Roto Molding Machines with Automatic Mold Temperature Control

Roto molding, also known as rotational molding, is a manufacturing process used for creating hollow plastic products. Roto molding machines are used in this process to produce a variety of products such as tanks, containers, toys, and more. These machines are designed to provide efficient and high-quality production, making them an essential tool in the plastic industry.

The Roto Molding Machines are equipped with automatic mold temperature control to ensure consistent and precise temperature during the molding process. This feature helps in achieving uniform thickness and smooth surface finish for the final product.

The Roto Molding Machines come with the option of open or closed mold type. The open mold type is suitable for larger products, while the closed mold type is ideal for smaller and more intricate designs. This versatility makes the machine suitable for a wide range of products.

The Roto Molding Machines offer two heating methods - electric and gas. The electric heating method is preferred for smaller machines, while the gas heating method is more suitable for larger machines. This allows for flexibility and customization according to the production needs.

The Roto Molding Machines require a 3-phase, 380V, 50Hz power source. This high-power requirement ensures efficient and continuous production, making it suitable for large-scale manufacturing.

The Roto Molding Machines specialize in rotational molding, a process that involves heating and rotating a hollow mold filled with plastic resin. The rotation of the mold ensures even distribution of the molten resin, resulting in a strong and uniform product.

We offer a range of Roto Molding Machines to suit different production needs. Our product line includes roto blow molding machines, lab size roto molding machines, and large roto molding machines. These machines are designed to provide efficient and high-quality production, making them an essential tool in the plastic industry.

Roto Molding Machines are an essential part of the plastic industry, providing efficient and high-quality production for a variety of products. With features like automatic mold temperature control, mold type options, and flexible heating methods, these machines offer versatility and customization for different production needs. Choose from our range of options and experience the benefits of Roto Molding Machines for your manufacturing process.

| Roto Molding Machines | |

|---|---|

| Product Name | Roto Molding Machines |

| Miniature Roto Molding Machine | Yes |

| Technical Parameters | |

| Mold Temperature Control | Automatic |

| Material | Polyethylene |

| Capacity | 500-1000 Liters |

| Molding Type | Rotational Molding |

| Productivity | 10-20 Cycles Per Hour |

| Mold Cooling Method | Direct/Indirect |

| Power Source | 3-phase, 380V, 50Hz |

| Mold Type | Open/Closed |

| Mold Release Method | Air Blowing |

| Mold Material | Aluminum/ Stainless Steel |

The Roto Molding Machine, also known as a Rotational Molding Machine, is a specialized equipment designed for the manufacturing of large hollow plastic products. It is the most efficient and cost-effective method for producing rotationally molded products, with a wide range of applications in various industries.

Our Roto Molding Machines are proudly manufactured in Zhejiang, a hub for plastic machinery and technology in China. With years of experience and expertise, our brand has become synonymous with high-quality and reliable roto mold machines.

The Roto Molding Machine is specifically designed for producing large hollow plastic products, such as water tanks, septic tanks, playground equipment, storage containers, and many more. Its versatility makes it suitable for a wide range of industries, including automotive, construction, agriculture, and water treatment.

Our Roto Molding Machines come with both open and closed mold options, giving you the flexibility to choose the best molding method for your product. The open mold allows for easy loading and unloading of the product, while the closed mold provides a more controlled environment for the rotomolding process.

The mold cooling method is crucial in the rotomolding process to ensure the final product has a consistent wall thickness and is free from defects. Our Roto Molding Machines offer both direct and indirect cooling methods, using either air, water, or a combination of both to achieve optimal cooling.

The Roto Molding Machine is designed for high productivity, with a cycle time of 10-20 cycles per hour, depending on the size and complexity of the product. This allows for efficient production and a quick turnaround time, making it ideal for large-scale manufacturing.

Our Roto Molding Machines are capable of producing products with a capacity ranging from 500 to 1000 liters. This makes it perfect for creating large hollow plastic products for various applications, such as water storage, chemical storage, and industrial containers.

With the combination of advanced technology, high-quality materials, and precise engineering, our Roto Molding Machines offer superior performance and durability. The gearing system, gearing motor, and arms of the machine are designed for optimum efficiency and long-lasting use.

In conclusion, the Roto Molding Machine is an essential equipment for the manufacturing of large hollow plastic products. Its versatility, efficiency, and superior performance make it the preferred choice for many industries. Choose Rotational Molding as your partner for all your rotomolding needs, and experience the best in the industry.

Brand Name: Rotational Molding

Place of Origin: Zhejiang, China

Heating Method: Electric/ Gas

Productivity: 10-20 Cycles Per Hour

Mold Cooling Method: Direct/Indirect

Mold Material: Aluminum/ Stainless Steel

Application: Manufacturing Of Large Hollow Plastic Products

Key Features:

The Roto Molding Machines are carefully packaged to ensure safe and secure transportation to our customers. Here is a breakdown of our packaging process:

We offer a variety of shipping options for our Roto Molding Machines to accommodate the needs of our customers:

For domestic shipments, we work with trusted freight carriers to ensure timely and reliable delivery to our customers. The shipping cost will be calculated based on the destination, size, and weight of the machine.

We also offer international shipping for our Roto Molding Machines. Our team works closely with our customers to determine the best shipping method and handle all necessary customs and documentation. The shipping cost will be calculated based on the destination, size, and weight of the machine, as well as any additional fees or taxes required for international shipments.

In urgent cases, we offer expedited shipping options for an additional cost. Please contact us for more information and availability.

We strive to provide the best packaging and shipping services for our customers to ensure the safe and timely arrival of our Roto Molding Machines. If you have any questions or special requests, please don't hesitate to contact us.