Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

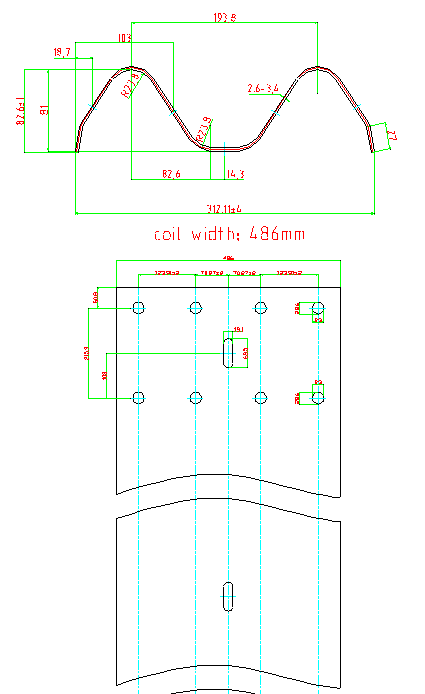

Two and Three Waves Guard Rail Roll Forming Machine

Profile:

All of our machine profile is customized, above profile is only for your reference.

1. Coil width: 486mm/756mm

2. Thickness: 2.5-3.5mm

Layout:

Hydraulic decoiler—Leveling—Punching—Roll Forming—Cutting—Out table

Specifications:

| Item NO |

Description |

Offered specification |

| 1 | Roll Forming Machine | Guardrail

|

| 2 | Material Width | 486mm/756mm |

| 3 | Rolling Speed | 15m/min(including punching and cutting) |

| 4 | Rolling Thickness | 2.5-3.5 mm |

| 5 | Control System | PLC (Panasonic) as list in the note |

| 6 | Un Coiler | 10 ton hydraulic de-coiler with coil car |

| 7 | Leveling Station | 1 station (three rollers over four), 7.5kw |

| 8 | Servo feeding to punching | 5.5kw |

| 9 | Punching | Two sets |

| 10 | Roller Stations | 18 stations (according the final design) |

| 11 | Roller Material | GCR15, HRC58-62℃ coated with chrome |

| 12 | Shaft Material and DIA | ¢100mm, material is 45# forge steel |

| 13 | Maim Motor Power | 45kw |

| 14 | Hydraulic Station Power | 30kw |

| 15 | Hydraulic Pressure | 25-30Mpa |

| 16 | Cutting mode | Hydraulic track cutting by servo motor 5.5kw |

| 17 | Material Of Cutting | Cr12Mov quenching 58-62℃ |

| 18 | Structure Of The Stations | Guide pillar |

| 19 | Tolerance | 3m+-1.5mm |

| 20 | Electric Source | 380V, 50HZ,3 phase According to customer’s require

|

| 21 | Way Of Drive | By gearbox |

| 22 | Color Of The Machine | Yellow and blue |

| 23 | Container Need | 1 x40 feet & 1 x20 feet |

| 24 | How to change the profile | Change the last three roller stations which is in one cassette |

Main Features

1. The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and process as a whole after welding. It has the ability of strong loading and stable operation when running the machine.

2. All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3. We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

4. It is very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.