Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Portable Metal Standing Seam Roof Panel Roll Forming Machine

PEB stands for Pre Engineered Buildings. It can fulfill a wide range of structural and aesthetic design requirements. This flexibility allows PEBs to fulfill a vast range of building configurations, custom designs, requirements and applications. The technology offers several advantages over conventional concrete or steel structures, both in terms of cost and time savings.

1. Specification of the material

| 1 | Suitable Material | PI/ PPGI |

| 2 | Width of the raw material | 1250mm |

| 3 | Thickness | 0.3-0.8mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine

| YX28-200-1000/ YX29-210-1050 |

| 2 | Machine structure

| Guide pillar structure |

| 3 | Total power | Motor power-7.5kw Hydraulic power-5.5kw |

| 4 | Roller stations

| Up layer- 20 stations Down Layer-20 stations |

| 5 | Productivity

| 0-15m/min |

| 6 | Drive system

| By chain |

| 7 | Diameter of shaft

| ¢70mm solid shaft |

| 8 | Voltage

| 380V 50Hz 3phases (Customized) |

| 9 | Color Of The Machine

| Bule and yellow |

| 10 | Deliver time

| 70 days |

| 11 | Terms Of Payment

| 30%T/T 70% pay before shipment |

3. Profile drawing

Up Layer

Down Layer

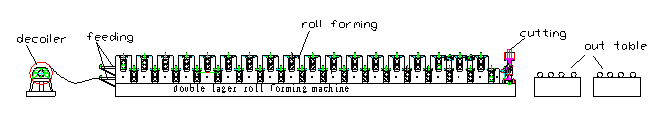

4. The Chart of Process Flow

Hydraulic Decoiler—Roll Forming—Cutting—Auto Stacker

5. Specification of Components

(1) 5T Hydraulic Un-coiler

(2) Main Roll Forming Machine

(3) Hydraulic Cutting System

(4) Computer Control Cabinet

(5) Auto Stacker