Zhangjiagang City Saibo Science & Technology Co.,Ltd |

|

Verified Suppliers

|

|

Tile Roll Forming Machine with chrome

1. Specification of the material

| 1 | Suitable Material | Colored Steel plate, Galvanized steel |

| 2 | Width of the raw material | 1200mm |

| 3 | Thickness | 0.4-0.6mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | YX39-153-918

|

| 2 | Machine structure

| Wall panel structure

|

| 3 | Total power | Motor power-5.5kw Hydraulic power-5.5kw |

| 4 | Roller stations

| About 19 stations |

| 5 | Productivity

| 2-4m/min |

| 6 | Drive system

| By chain |

| 7 | Diameter of shaft

| ¢70mm solid shaft |

| 8 | Voltage

| 380v 50Hz 3phase |

| 9 | Color Of The Machine

| Yellow and blue |

| 10 | Container need

| 40GP container |

| 11 | Deliver Time

| 70 days |

| 12 | Terms Of Payment

| 30%T/T 70% pay before shipment |

3. Profile drawing

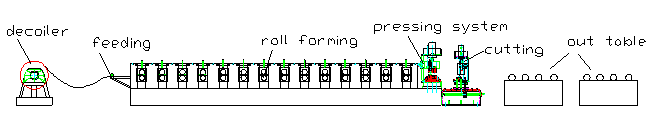

4. The Chart of Process Flow

5. Specification of Components

(1) 5T Hydraulic Un-coiler

(2) Main Roll Forming Machine

(3) Machine Structure

(4)Pressing System:

(5) Hydraulic cutting system

(6) Computer Control Cabinet