Xiamen New KaiHang Machinery Co., Ltd |

|

Verified Suppliers

|

|

Tapered standing seam roll former with concealed fixing, two rows, manual/ auto design

Quick Detail:

Brief Introduction standing seam roof sheet roll forming machine:

There are standard standing seam roof panels such as 50-333, 50-429, 65-305, 65-333, 65-400, 65-459 and 65-500, and these profiles can be straight sheet, or tapered sheets. Like other concealed fixing standing seam roofing sheet roll forming machine, standing seam sheet roll forming machine can also handle with different widths material and manufacture different standing seam sheets on the same machine, like one machine can make both 65-400 and 65-450 type roof panels which joint with each other through clips too.

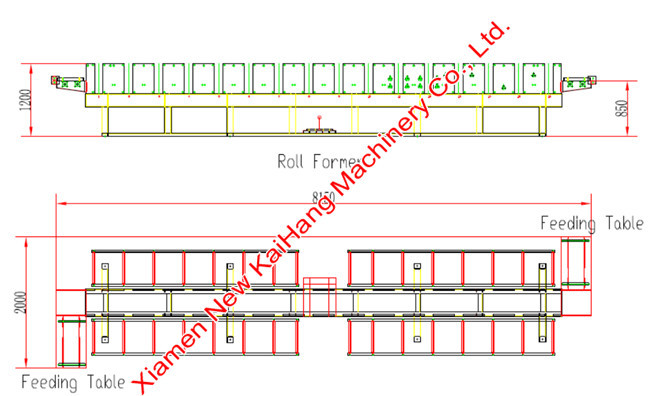

This tapered roll forming machine is with two sides roll former, cut pieces and feed in piece by piece, it is very simple and economic design.

Machine list:

Description/Technical Parameter details of complete line:

Manual feed in

Feed in piece by piece by manual

Min product length: 2 meters

Gear/Sprocket driving, 16 stages to form on single side

Double sides form the profile

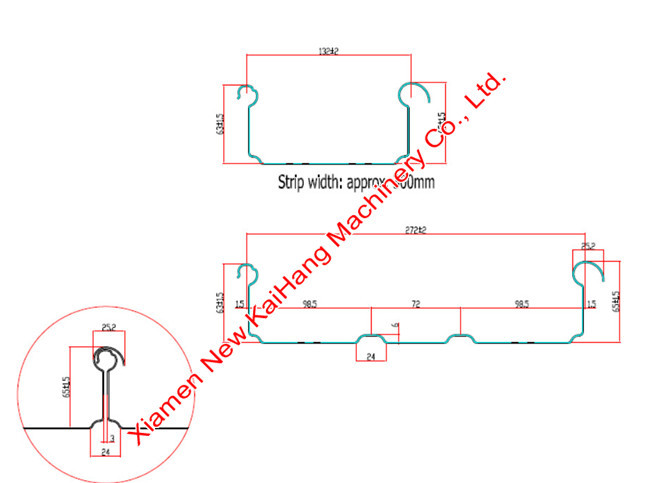

This roll former can do the profile with min. effective width 130mm /no bottom ribs or the profile with min. effective width 272mm including two bottom ribs, through changing some rollers by manual.

Rollers manufactured from 45#, CNC lathes, hard Chrome Coated

Shafts Diameter=ф75/60mm, Precision Machined

Main motor =5.5 KW with gear box, Frequency speed control

Mesh cover above the roll former NOT required

Un-powered simple rack fixed at both sides

Manual operation only, FW/REV/STOP

Inverter for frequency speed adjust by manual is included

Profile Drawing/Layout/Equipment reference pictures: