Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Full Automatic Color Steel IBR 686 Roof Panel Roll Forming Machine PLC Control

1. Description Of Roof Panel Roll Forming Machine

Color steel tile is made by using the color steel plate after the rolling, become the steel plates with various kinds of wave shapes. It is suit for the industrial and civilian constructions, warehouses, the big cross-beam structure houses’ roof, metope and the inner/outer metope’s decoration. It has the good characteristics, such as light weight, high strength, colorful, easy installation, anti-seismic, fire-proofing, rain-proof, long service life, maintenance free, etc. Now, it is widely popularized and used.

Our factory is producing high quality color steel tile roll forming machines, and exported to India, Iran, Russia, Vietnam, Ghana, Tanzania, etc.

2. Production Flows Of Roof Panel Roll Forming Machine

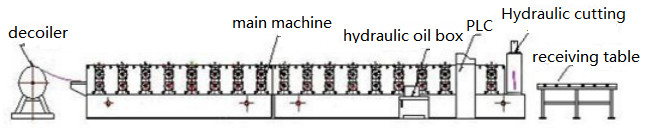

Decoiler → feeding table (sheet metal is put by guiding platform) → main forming machine → Hydraulic cutting system → Receiving table

3. Main Components Of Roof Panel Roll Forming Machine

| Manual Decoiler | 1 Set |

| Feeding Table | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Technical Details Of Roof Panel Roll Forming Machine

| Machine Specifications | |

| Weight | About 4.5tons |

| Size | About 6.5M*1.3M*1.2M(length x width x height) |

| Color | Main color: bule or as your need |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | GI PPGI GL PPGL |

| Thickness | 0.3-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 13 |

| Diameter of forming rollers shafts | 70mm |

| Roll Forming Speed | 15m/min |

| Forming rollers material | 45# steel, coated with chromed treatment |

| Cutter material | Cr12MOV, with quenched treatment |

| Controlling system | PLC |

| Electric Power requirement | Main motor power: 4kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

5. Advantages Of Our Roof Panel Roll Forming Machine

· More than 10 engineers and More than 10 designers with more than 10 years experience

· We have completed production system. And have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.

· Our machine's warranty period is 12 months and and we supply the technical support for the whole life of the equipment.

· We have professional engineer to check the quality of all parts. we do every step carefully to make sure the quality.

6. Application Of Roof Panel Roll Forming Machine

This machine is widely used in the production of the metal roof sheets and wall panel. our machines are exported to many countries: Rwanda, Thailand, Philippines, Dubai, USA, South Africa, Peru, Russia, Saudi Arabia, Malaysia, Indonesia, etc.

7. Product photos Our Roof Panel Roll Forming Machine

8. FAQ

Q. Will i receive a good machine ? Same with my wanted ?

A: Yes sir/Madam. We will do the machine according to your profile

drawing . About the profile drawing, we will confirm with you again

before producing your machine. Then, after the machine finished, we

will test the machine and guarantee the machine you received is a

good machine. Because after you satisfied with the machine, and

then you pay balance.

Q. I do not know about the machine and do not know how to install

it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for

the travel expense such as visas, round tickets, hotels, and food

Salary of 100USD per day per person (from departure from our

factory, until we are back to our factory). You also need to take

care of his safety.

Q. How can I start working?

The machine is tested well and the wires are connected.

When you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.