Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Galvanized Metal Composite Floor Deck Panel Roll Forming Machine For Steel Flooring Deck

1. Description of floor decking roll forming machine:

In short,Roof decking floor profiles are typically used as the structural component. The steel decking floor is a cold-formed steel sheet. Metal Decking use in roof and floor systems for supporting the concrete or insulating membrane of a roof. Its design and construction magnify properties of the steel.

The combination of floor deck and concrete serves the dual purpose of permanent form and positive reinforcement. Floor deck has a special embossment pattern. When concrete is poured on to floor deck, it binds to the embossment, interlocking to form a composite foundation for construction.

2. Technical details of floor decking roll forming machinery:

| floor decking roll forming Machine Specifications | |

| Weight | About 12.5tons |

| Size | About 12.5mx1.5mx1.3m(length x width x height) |

| Color | Machine Main color: blue or can as your requirement |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils,color steel |

| Thickness | 0.8-1.5mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 26stations |

| Diameter of forming rollers shafts | 90mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 15.5kw+15.5kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

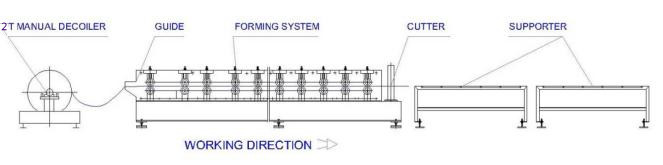

3. Main components of floor decking roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

We are very rigorous in every tiny detail,including raw material and making machines.

6. Application

This machine is widely used in the production of the roof and floor systems. Metal floor decking roll forming machine popular sell in many countries, such as United States, Mexico, Chile, Peru, Australia, Rwanda, Nigeria, Kenya, Dubai, Qatar, Thailand, India, Indonesia, Malaysia, Colombia Coil width before rolling is 1200mm /1220mm / 1250mm. Material common is PPGI material, material thickness common between 0.8-1.5 mm.

7. Product photo

FAQ

Q. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand components.

Q:How can I trust you that machines pasted testing running before shipping?

A:1) We record the testing video for your reference.

2) We welcome you visit us and test machine by yourself in our factory.

Q1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

Welcome to inquiry.