Xiamen BMS Group |

|

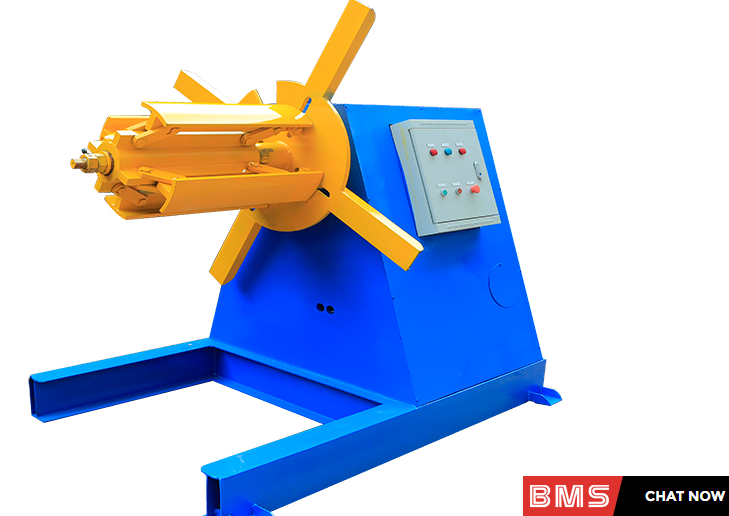

Auto Change Type C75-300 Purlin Machine With 5 Ton Hydraulic Decoiler

1. Product description

| Weight | 12tons |

| Shaft material | 75/90mm |

| Production Capacity | 18-20m/min |

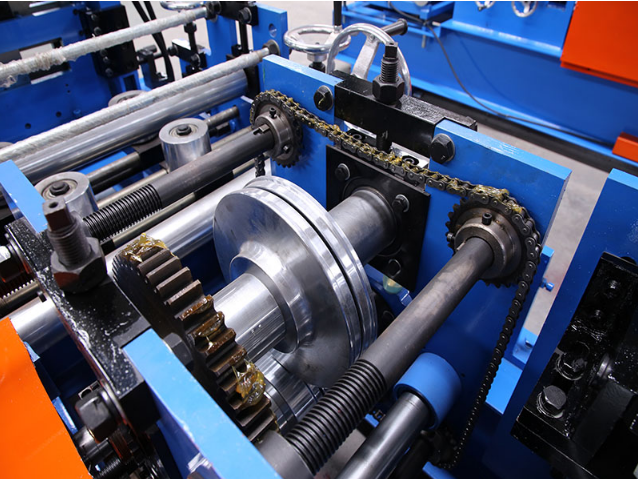

| Material of rollers | Gcr15 |

| Roller material | Cr12mov |

| Condition | New |

| After-sales Service | Online support, Free spare parts, Field installation, commissioning and training |

| Yield strength | 345-550Mpa |

2. Profile drawing

3. Work Follow

2) C purlin machine pre-cutter&Punching Device

Pre-punching and pre-cutting, use the same hydraulic system

Hydraulic motor:7.5KW,Hydraulic pressure range:0-25Mpa(250Bar)

Punching and Cutting tool material:mold steel Cr12MoV(=D2 steel, with onemillion times punching/cutting life), Heat treatment to HRC58-62 degree3-cylinders hole punching system for punching both on web