RKENS TECHNOLOGY CO.,LTD |

|

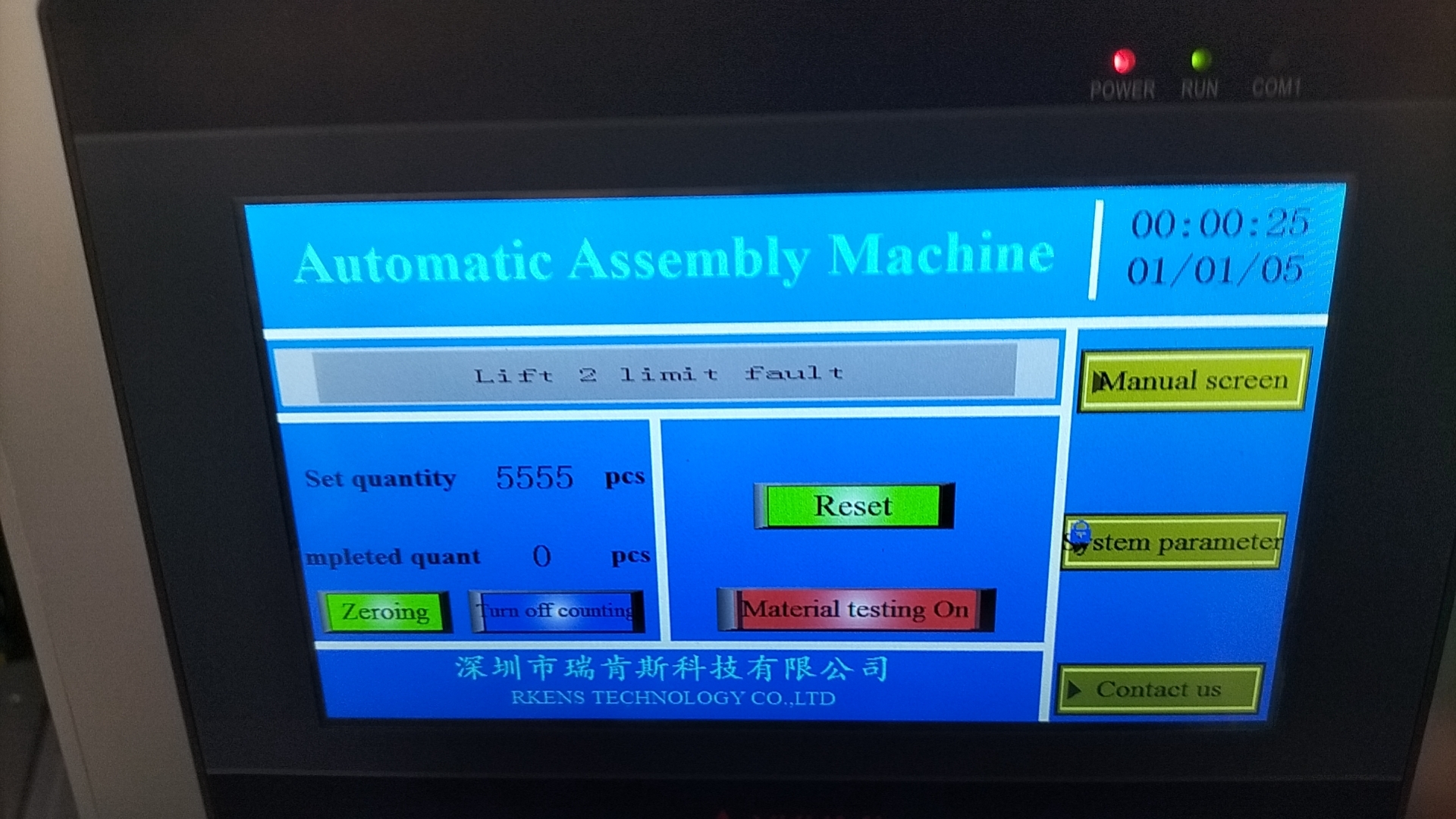

Customized Non-standard Full Automatic Plastic Parts Assembly Machine Hardware Screw Assembly

Working principle:

The machine is a customized assembly machine for plastic parts. It can assemble two plastic parts together automatically. It can auto feeding, installing. No need labor.

The storage bin is full of large plastic parts. When the vibration bowl is lower than the set quantity, the storage bin will automatically unload big plastic part. The vibration bowl sorts out materials and enters line vibration, and small plastic parts sort and discharge materials and enters line vibration. Both sides are directly vibrated and pushed into the mold for assembly. After assembly, the machine automatically picks up the material, puts it into the conveyor belt in the same direction, and transports it to the designated location (the cylinder can block and discharge the material to position the material). The sensor senses the material and sends a signal to the laser marking machine for laser marking. (the laser marking machine is provided by the buyer).

Machine introduction:

The automatic assembly machine includes two feeding system. Vibration bowl feeding and linear track feeding.

1. Vibration feeding

① Pour the material into the vibrating bowl, turn on the vibration plate switch, adjust the vibrating bowl speed regulator, make the material move upward along the circumference of the vibrating bowl, and automatically check its direction. If the direction is wrong, the material will fall back into the vibrating bowl. If The direction is correct, we will continue to go up.

② When the material reaches connection area of bowl vibration and linear vibration, a certain distance between the vibrating plate and the linear feeding must be maintained.

2. Linear feeding

① When the material passes through the flat surface and reaches the feeding port, it stops.

②The vibration bowl sensor and the machine sensor are two sets of electric eyes to control the entry of materials.

③When the material is arranged on the vibration bowl sensor and is illuminated by the electric eye, it means that the material is full. The vibration feeding of the vibrating bowl needs to be temporarily stopped. After the main mechanism digests the material, the vibrating feeder can continue feeding.

④ There is a buffer distance between the two sets of electric eyes of the vibration bowl sensor and the machine sensor. In order to allow the main mechanism to operate smoothly, the feeding of the vibration plate needs to be controlled to achieve a balance between supply and demand and reduce material jamming.

⑤ There needs to be a certain distance between the linear feeding track and the feeding seat.

Assebly plastic parts samples

Plastic parts assembly machine video: