Henan Fair Machinery And Equipment Co. LTD |

|

2022 High Quality Automatic Dry Mortar Production Line Use Twin Shaft Paddle Mixer

FIER dry mortar mixer adopts the paddle structure. There materials can lose weight instantly at the critical parabolic rotate speed

so that the best mixing effect can be achieved, and also the violent turnover speed shortens them mixing time to large the extent.

Our dry mortar machine is widely applied in the equipments of unitized mass production lines.

Application of Double Shaft Paddle Mixer

Our dry mortar machine is upgraded based on the traditional dual axle mixer to produce dry mortar.

Zero gravity mixer mainly used in the producing of cracking mortar, insulation mortar, binding mortar, plaster mortar, floor mortar, medium and high-grade putty powder etc.

Packaging & Delivery

1, For full container load, main body with plastic film surrounded or in nude, key parts and spare parts in strong export wooden or iron case. 2, For less than container load, main body and all spare parts in strong export wooden or iron case.

Delivery Time

Usually in stock, Shipped in 7 days after payment

Our service

1.According to your inquiry, We will reply to you in 24 hours.

2.Best After-sales: We will send the technical personnel to the

site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and

man-made factors, the damage caused by design, process and

manufacturing equipment, the seller is responsible for sending

people to offer free repair.

4.We will send the spare parts as soon as possible when necessary,

equipment repair parts provided by the seller are original,

authentic, quality goods.

Main characteristics:

1.Hydraulic door unloading , safety.

2.Thickening mixing drum .

3.Whole casting spiral stirring arm, high strength, wear resistance

, low resistance.

4.High wear-resistant alloy cast iron side plates.

5.Gearbox and spindle are used couplings directly drive , long

life, high mechanical efficiency.

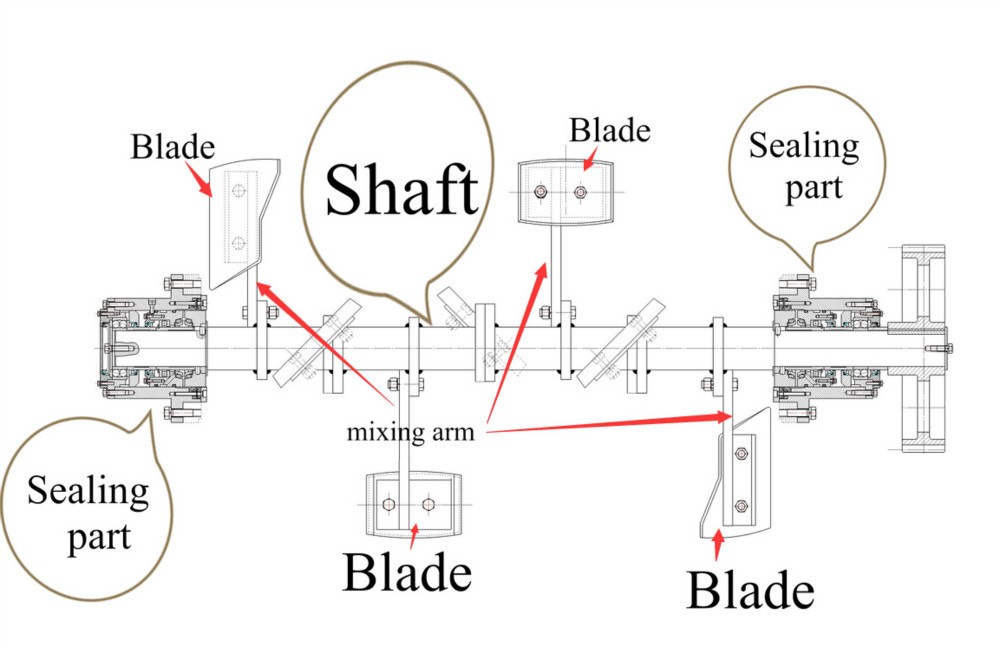

Mixing device

Arms are removable. Easy to install and maintain. Hollow shaft has

high torsional strength. The blade structure makes high mixing

efficiency and better homogeneity.

Parameter

Item | CDW1200 | CDW2000 | CSW2000 | CSW3000 | CSW4000 | CSW6000 | CSW8000 | CSW10000 |

Total capacity (L) | 1200 | 2000 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 |

Working capacity (L) | 480-720 | 800-1200 | 800-1200 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

Mixing power(L) | 30 | 37 | 18.5*2 22*2 | 22*2 30*2 | 30*2 37*2 | 37*2 45*2 | 55*2 75*2 | 75*2 90*2 |

Knife device number | 3 | 4 | 4 | 6 | 6 | 6 | 6 | 6 |

Knife device power (kw) | 5.5*3 | 5.5*4 | 5.5*4 | 5.5*6 | 5.5*6 | 5.5*6 | 5.5*6 | 5.5*8 |

Weight (KG) | 3000 | 4000 | 4500 | 5000 | 7000 | 7000 | 9500 | 11000 |

Features of FAIR automatic dry mortar production line:

1. It features magnificent appearance, good quality, high

productivity and accurate mortar proportioning.

2. The dry mortar production line uses a centralized control

system, making the equipment easy to operate.

3. According to the layout type, it can be classified into tower

type, self tower type and series type. Its up to the customers

workshop area. The needed area is 500~5000m2.

4. We can provide one-stop service from design to installation

according to our customers' specific requirement.

Pre-sale Service:

24 hours online; CE, ISO Certification available.

More than 30 years experience in construction platform industry.

Customized service is available, including capacity, productivity,

color, design, depend on your idea!

After-sales Service:

Training how to install and use the machine;

Engineers avilable to service machinery overseas;

Sufficient spear parts in stock provide for equipment whole life.