Wuxi Fenigal Science & Technology Co., Ltd. |

|

Technological Process:

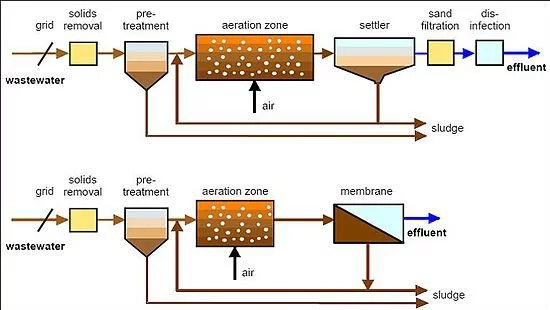

Sewage → Grille → Regulating pond → MBR Bioreactor → Discharge(reuse)

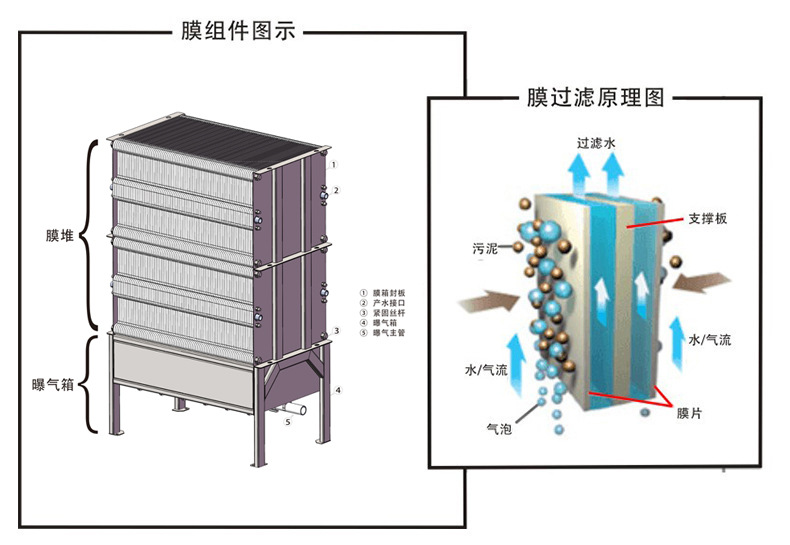

1. Temperature: 5ºC~45ºC, average membrane aperture 0.10 μm.

2. PH: 2~12, membrane thickness: 40μm.

3. Outlet water turbidity: <1 NTU , outlet water SS <1mg/L.

4. Membrane area: 8m2, advised gas-water ratio: 25:1~30:1.

5. Operating pressure: -0.01 ~ -0.03MPa.

Membrane Bioreactor (MBR) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class A+” treated effluent, suitable for reuse in “risk category high” applications or for discharge to sensitive environments.

The standard treatment process includes influent screening, balance tank mixing, anoxic & aerobic treatment, flat sheet membrane filtration with air scouring and CIP system, and effluent disinfection (hypochlorite dosing). Membrane bioreactors are constructed of corrosion resistant FRP, and are self-contained, modular systems for easy deployment to remote locations.

STANDARD SPECIFICATIONS

| Parameter | Units | MBR-020 | MBR-045 | MBR-060 | MBR-075 | MBR-155 | MBR-225 | MBR-315 | |

| Treatment capacity (min/max) | m3/day | 10 / 20 | 22.5 / 45 | 30 / 60 | 37.5 / 75 | 77.5 / 155 | 112.5 / 225 | 157.5 / 315 | |

| *1Balance tank volume (recommended) | m3 | 21 | 47.1 | 62.9 | 78.6 | 162.4 | 235.7 | 330 | |

| *1Treated effluent tank volume (recommended) | m3 | 20 | 45 | 60 | 75 | 155 | 225 | 315 | |

| Sludge tank volume | m3 | 3.5 | 9.5 | 13.5 | 22.5 | 32 | 46 | 64 | |

| Sludge waste volume (max) | m3/month | 5.3 | 13.2 | 17.5 | 21.9 | 45.3 | 65.8 | 92.1 | |

| *2Irrigation pump duty | m3/hr @ 500 kPa | 2.5 | 5.6 | 7.5 | 9.4 | 19.4 | 28.1 | 39.4 | |

| Screen wash water supply | m3/hr @ 500 kPa | 1.1 | 2.2 | 2.2 | 2.2 | 5.5 | 7.5 | 11 | |

| Ambient temperature (min/max) | °C | 1 / 43 | |||||||

| Power supply | - | AC 415V, 3 Phase, 50 Hz (other voltages and frequencies available on request) | |||||||

| Power con- sumption | MBR plant | kW | 9 | 19 | 26 | 36 | 42 | 65 | 83 |

| *2, *3Recirculation pump | 0.75 | 1.1 | 1.1 | 1.5 | 2.2 | 3 | 4 | ||

| *2Irrigation pump | 0.75 | 1.5 | 2.2 | 2.2 | 7.5 | 7.5 | 11 | ||

| Footprint | FRP bioreactor(s) & access platform(s) | m | 6 x 3.2 | 9 x 3.2 | 12 x 3.2 | 12 x 3.2 | 12 x 5.6 | 12 x 8.8 | 12 x 12 |

| Containerised plant room | m | *4N/A | 6 x 2.4 | ||||||

| Sludge tank(s) | m | Ø1.6 | Ø2.6 | Ø2.97 | Ø3.57 | Ø3.95 | 7.7 x 3.55 | 8.5 x 3.95 | |

| Characteristics | Units | Influent | Effluent |

| Temperature | °C | 15~35 | - |

| *5pH | pH units | 6.5~8.5 | 6.5~8.5 |

| *6Biological oxygen demand (BOD) | mg/L | *7≤350 | <10 |

| Suspended solids (TSS) | mg/L | *7≤350 | <10 |

| Emulsified oil and grease | mg/L | <2.0 | - |

| Free oil & grease | mg/L | <0.1 | - |

| Total nitrogen (T-N) | mg/L | <50 | <40 (or <10 mg/L reduction from influent value) |

| Total phosphorus (T-P) | mg/L | <16 | 4~12 (variable according to coagulant dose rate) |

| Total dissolved solids (TDS) | mg/L | <2,000 | - |

| Turbidity | NTU | - | <2 (95%ile) |

| E.Coli | cfu/100 mL | - | <1 |

| Coliphages | pfu/100 mL | - | <1 |

| Clostridia | cfu/100 mL | - | <1 |

| Free chlorine | mg/L | - | 0.2~2 |

| *2UV dose | mJ/cm2 @ 70% UVT | 40 | |

| Bacteria removal (membrane only) | Log | *8≥4 | |

| Virus removal (membrane only) | Log | *8≥1 |

*1 Sold separately, *2 Optional equipment, *3 Sizing based on recommend treated effluent tank volume, *4 Plant room integral to bioreactor, *5 Caustic dosing may be required where influent alkalinity is inadequate, *6 Sucrose dosing may be required where ratio of BOD to TKN is ≤5, *7 Typical composition of untreated domestic wastewater; higher/lower design values available on request, *8 Additional log credits are available with UV and chlorination;

STANDARD INCLUSIONS + OPTIONS

✓= Standard Supply, o = Optional Supply, - = Not Available

| Equipment | MBR-020 | MBR-045 | MBR-060 | MBR-075 | MBR-155 | MBR-225 | MBR-315 | ||

| Automatic inlet screen (2 mm in two dimensions) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Influent mixing pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Influent feed pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| FRP bioreactor(s) with aluminium access platform(s) & ladder(s) | Aerobic zone with submersible aerator & MLR pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| MBR zone with flat sheet membranes and submersible RAS/WAS pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| CIP/membrane flush tank | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Bioreactor roofing (COLORBOND® steel sheeting) | o | o | o | o | o | o | o | ||

| Plant room with air conditioning, overhead lighting & GPOs for maintenance | Chemical dosing | Coagulant | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Hypochlorite | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Sucrose | o | o | o | o | o | o | o | ||

| Caustic | o | o | o | o | o | o | o | ||

| MBR permeate pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Treated effluent tank recirculation pump | o | o | o | o | o | o | o | ||

| Pressurized UV reactor (non-validated*1) | o | o | o | o | o | o | o | ||

| PLC control system with touch screen HMI | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Externally mounted MBR air scour blower | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Sludge tank with supernatant sampling points & discharge valves | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Supernatant sump with submersible pump & level control | o | o | o | o | o | o | o | ||

| Irrigation pump with level control & mechanical flow totaliser / flow transmitter | o | o | o | o | o | o | o | ||

| Instrumentation | Standard package | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Premium package with remote monitoring | o | o | o | o | o | o | o | ||

| Instrumentation & Controls | Standard package | Premium package | |

| Level switches | Balance, bioreactor and treated effluent tank | ✓ | - |

| Chemical dosing & sludge tank float level switches | ✓ | ✓ | |

| Level transmitters | Balance, bioreactor and treated effluent tank | - | ✓ |

| Pressure transmitters | Membrane differential pressure | ✓ | ✓ |

| Pressure switches and gauges | ✓ | ✓ | |

| Flow transmitters | Influent feed, MLR and RAS/WAS | ✓ | ✓ |

| Permeate and irrigation pump (with optional irrigation pump) | - | ✓ | |

| Flow indicator | Permeate flow | ✓ | - |

| Mechanical flow totaliser | Irrigation pump (with optional irrigation pump) | ✓ | - |

| Analysers | Aerobic zone dissolved oxygen | ✓ | ✓ |

| Aerobic zone pH analyser | - | ✓ | |

| MBR zone mixed liquor suspended solids | - | ✓ | |

| Permeate turbidity | - | ✓ | |

| Permeate pH and free chlorine | - | ✓ | |

| UV intensity sensor (with optional UV steriliser) | - | ✓ | |

| Variable speed drives | Influent feed pump | - | ✓ |

| Submersible aerator | ✓ | ✓ | |

| MLR pump | - | ✓ | |

| RAS/WAS pump | - | ✓ | |

| MBR permeate pump | - | ✓ | |

| Remote monitoring & control capabilities | - | ✓ | |

More features:

1. Because of the high-efficiency solid-liquid separation, it can efficiently remove the SS, colloidal material and dead microbe in the sewage, no need sedimentation tank, or filter device, nor other solid-liquid separation device.

2. The MBR can make the biomass in biological treatment unit maintain high concentration, thus highly improve the volume loading. Meanwhile, the high efficient membrane separation can shorten the HRT. The device is with a compact structure and small space occupation.

3. MBR can filter out bacteria, part of the harmful material such as virus, it can obviously save dosing disinfection dosage, greatly improve the quality of the output water and reduce the operating cost and widen the scope of application of water.

4. Due to the strong interception function of MBR, it can keep the microbe in the reactor to avoid the loss of all kinds of microbe groups, which is good for the growth of the bacteria (such as the nitrifying bacteria), at the same time, it can lengthen the residence time of difficult degradable macromolecule organics to improve the decomposition so as to make the metabolic system process smoothly. The system has a strong impact resistance and wide suitability.

5. It can realize the completely separation of HRT and SRT. By the extended aeration, it can consume the organics, it can theoretically achieve the effect of no excess sludge emissions, thus reduce the surplus sludge treatment costs significantly.

6. The unique mode of operation makes the membrane surface no blocking, and the cleaning interval time is long. The way to clean the membrane is easy, since the membrane module can be separately cleaned, thus, the maintenance is convenience and simple.

The module design make the machine flexible, it is easy to expand the volume.

Advantages:

1) can save 50% area compare with the traditional process

2)Can treat high MLSS waste water (<10g/L), with long residence time for sludge(less30 days)

3)Steady Producing water quality for different water quality

4)Output Sludge value is low , lower the treatment sludge fee

6)The equipment is carbon steel Integration , biological oxidation and membrane reaction and back wash operate in same integration sewage treatment plant

(7)Compare the concrete structure , MBR Integration system /Package Sewage treatment Plant low occupy

area , and construction is easy . Only need do a base

(8)Can put underground , and surface can do greening