SPARK INDUSTRY (HENAN) CO.,LTD |

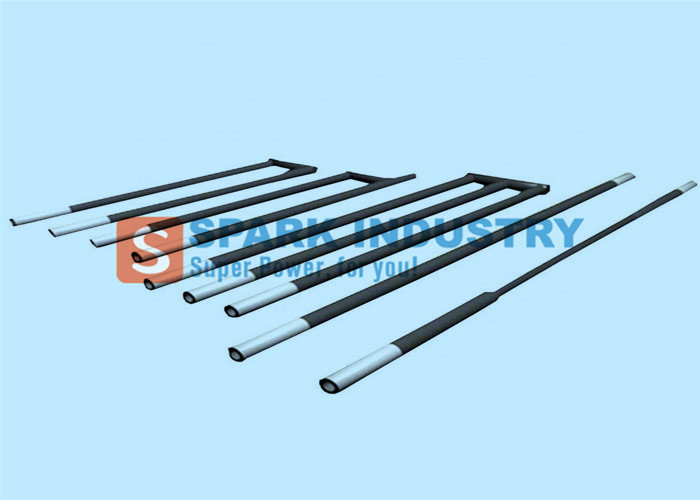

Silicon Carbide Resistance Heater Single Screw 1550 ℃

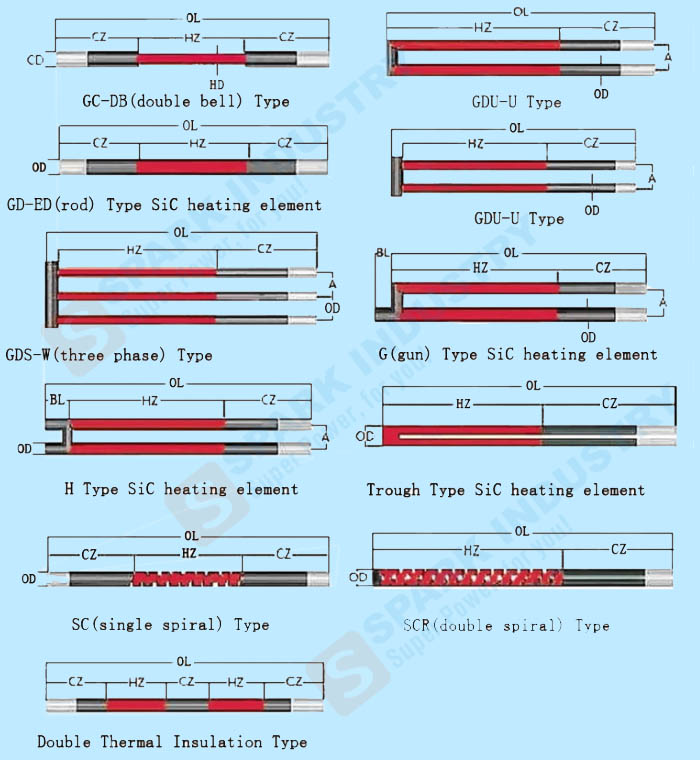

Silicon Carbide Heating RodSpecifications

1. High working temperature: 1500C.

2. Long time last.

3. Varous type available. Rod, U, W, Single Spiral, Double Spiral

Silicon Carbide Heating Rod Advantage .

1. High working temperature: 1500C (Surface Temperature)

2. Various shapes: Rod, U, W, Single Spiral, Doule Spiral shapes are availible.

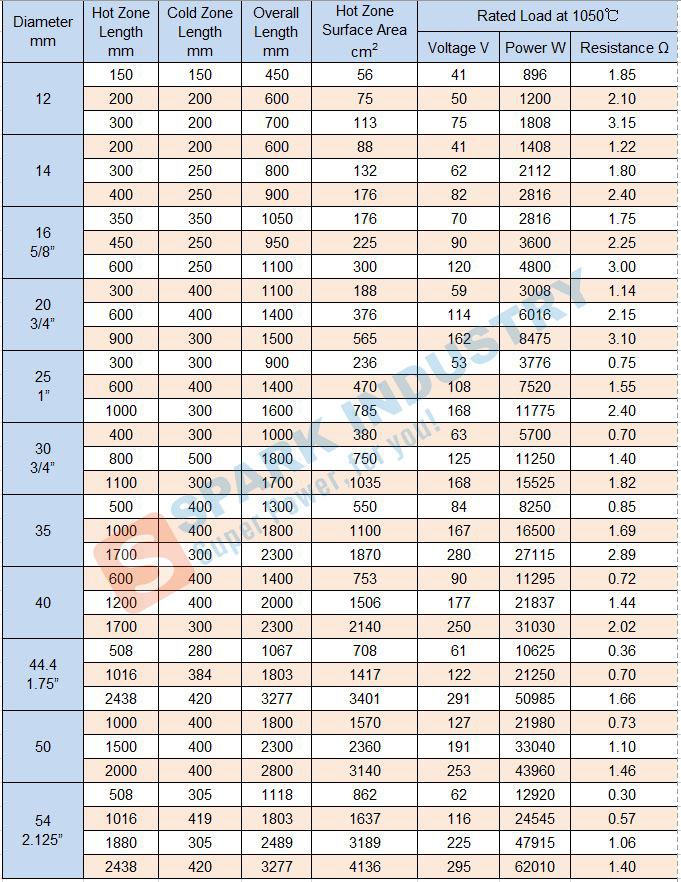

3. Large size range: Diameter 14-54mm, Length 200-4500mm.

4. Fast Delivery: Normal quantity can be ready in 10 days.

5. Very competitive prices.

How to Order Silicon Carbide Heating Rod

1. Choose the shape you need, like Rod, U, W, Single Spiral etc.

2. Out Diameter (OD)

3. Heating Zone Lengh (HZ)

4. Overall Length (OL)

5. Resistance you need.

Order Sample: Rod type, OD30mm, HZ300mm, OL800mm, Resistance 0.4ohms.

Normally the following should be given when describing any type of SiC heating elements:

Physical property of SIC heating element

| specific gravity | 2.6~2.8g/cm³ | bend strength | >300kg |

| hardness | >9MOH’S | tensile strength | >150kg/cm³ |

| porosity rate | <30% | radiance | 0.85 |

Recommended surface load and Influences to Surfaces of the Elements in Different Operating TemperatureS

| atmosphere | Furnace Temperature(°C) | Surface Load(W/cm2) | The influence on the Rod |

| Ammonia | 1290 | 3.8 | The action on SiC produces methane and destroys the protection film of SiO2 |

| Carbon dioxide | 1450 | 3.1 | Corrode SiC |

| Carbon monoxide | 1370 | 3.8 | Absorb carbon powder and influence the protection film of SiO2 |

| Halogen | 704 | 3.8 | Corrode SiC and destroy the protection film of SiO2 |

| Hydrogen | 1290 | 3.1 | The action on SiC produces methane and destroys the protection film of SiO2 |

| Nitrogen | 1370 | 3.1 | The action on SiC produces insulating layer of silicon nitride |

| Sodium | 1310 | 3.8 | Corrode SiC |

| silicon dioxide | 1310 | 3.8 | Corrode SiC |

| Oxygen | 1310 | 3.8 | SiC oxidized |

| Water-vapor | 1090-1370 | 3.1-3.6 | The action on SiC produces hydrate of silicon |

| Hydrocarbon | 1370 | 3.1 | Absorb carbon powder resulted in Hot pollution |

Notice for using and installing:

1. Heater should be protected against damp during storing or installing to ensure the performance of the heater.

2. In order to be sure of well-distributed lod of each and groups, heater should be divided before assembling. The tolerance of the resistance of each one cannot exceed by 10% each other.

3. Heater is hard and brittle, please be careful when assembling and maintaining so as to avoid damage.

4. When operating the electric furnace at the beginning, the voltage should be increased slowly and cannot be fully loaded at once. Otherwise the larger current will be resulted in the damage of heater.

5. When heater is damaged and need to be changed, the resistance of new one should follow the increasing resistance. If many are damaged or resistance increased too much, heater should be changed.