Active Member

|

[China]

Address: East gate 16, baoliansi road, XuZhou economic and technological development zone, JiangSu Province

Contact name:Will

Jiangsu SunRise Environmental Technology Co.,ltd |

|

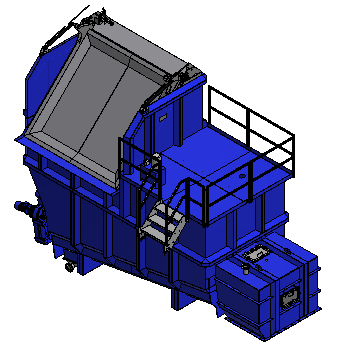

Model Is LXLC0120C Storage Material Raw Material Hopper

Raw Material Bins& Silo

The product line of bins includes raw material to meal bins and everything in between.

No matter what kind of meat, poultry or fish by-products you process, you will always need simple, rugged bins for moving, parking and storing everything from raw material and other inputs to your finished output.

Storage

In order to ensure the continuous supply of materials to the sintering machine, various raw materials have a certain storage time in the batching bin, and the storage time is determined according to the operation and maintenance of the raw material processing equipment. Generally, all materials are not less than 8h.

The storage time of various raw materials can be determined by referring to the table. To determine the storage time of the mixing material batching warehouse, the conditions of the mixing material yard supplying ore to the batching room and the influence caused by the sudden failure of the mixing and reclaimer should be considered.

The planned maintenance or failure time of the mixing material yard equipment should be longer The impact may not be considered. When this happens, the direct transport system of the storage yard temporarily supplies materials to the batching room. Silo anti-blocking measures Wet materials are easy to block the silo, and anti-blocking measures must be taken. According to the viscosity of the material, the lower part of the silo adopts different structural forms to prevent clogging.

For viscous materials, such as concentrates, fine ore with high viscosity, etc., the silo can be designed as a three-stage movable silo, and a vibrator is installed in the movable part, as shown in Figure a. For fine ore with lower viscosity, the upper part of the silo can be designed as a two-stage structure with a sudden spreading shape, and a vibrator is installed on the silo wall, as shown in Figure b.

For materials such as slaked lime and fuel, a vibrator can be installed directly on the wall of a general metal ore warehouse, as shown in Figure c. If the volume of the ore bin is large, it can be designed into an exponential curve to prevent blockage.

| designed volume | 20m³ |

| input format | side input |

| screw diameter | 500mm |

| screw quantity | 3.Pcs |

| material for body | carbon steel |

| hydraulic cover material | stainless steel |

| motor power | 3*4kw |

| motor brand | Simens |

| Reducer brand | JIE |

| shaft brand | SKF |

| shipping size | 7945*5365*2925 |

| shipping weight | 11000kg |