Shenzhen Honkia Prototype Co., Limited |

|

High Precision Sheet Metal Fabrication Stainless Steel Parts Thickness 3.5mm Tolerance ± 0.1 Mm

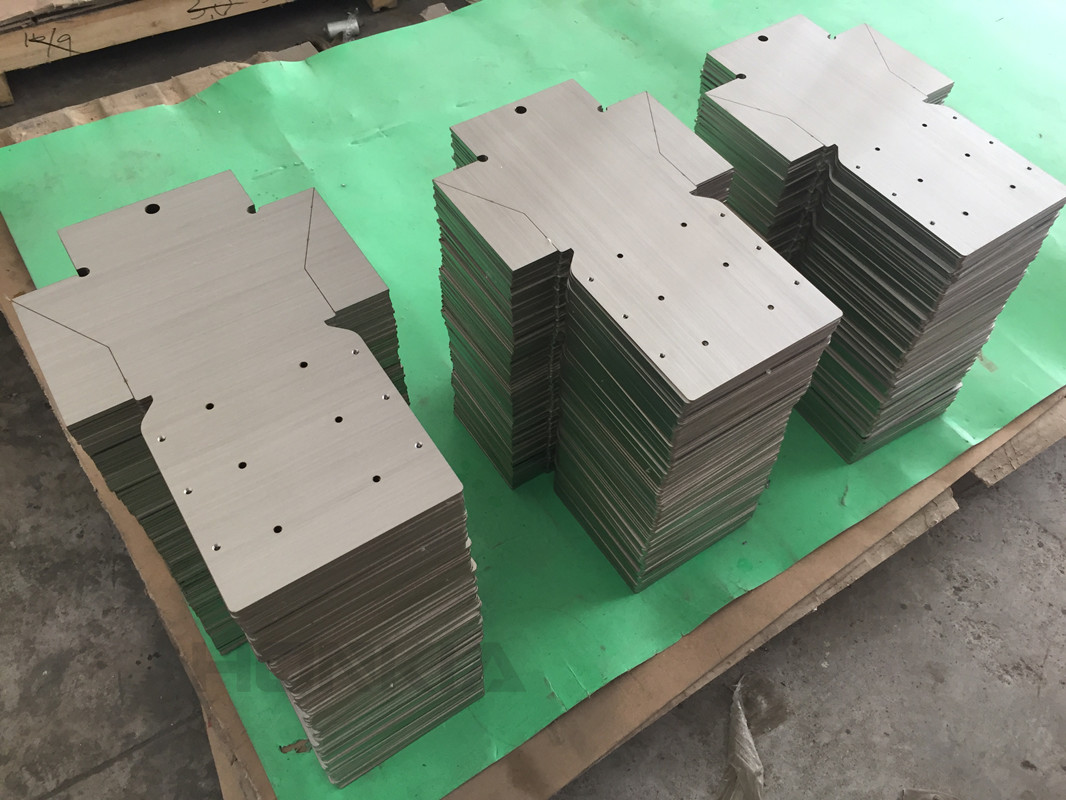

Customer was from Canada and ordered those sheet metal parts for their mechanical systems. Rapid prototype prior to low volume production was made to test the manufacturing capability, particularly bending tolerance.

Sheet Metal Fabrication involves cutting, punching, bending, stamping, and welding the metal sheet using specified tools and machines. The metal sheet can be made from various materials, such as iron, steel, aluminum, copper, brass, stainless steel or titanium, etc. the metal sheet thickness ranges from as thin as 0.2 mm to as thick as 10 mm or more.

Bending is the primary step for sheet metal fabrication, the bending features must be well considered during part design to have the part bent at tight tolerance, good performance, pleasant appearance, high productivity. Our bending tolerance is usually ± 0.1 mm as well as laser cutting, bending thickness ranges from 0.2 to 10.0 mm.

Manufacturing Tolerances:

Tolerances are one important consideration when designing and fabricating sheet metal parts. Tolerances refer to the allowable deviation from the desired dimensions and specifications, and are usually expressed in fractions of an inch or in millimeters. The tolerances depend on the specific application of the parts, and vary depending on the factors such as material used, manufacturing process, and required precision.

Sheet Metal Parts Design Considerations:

Designing sheet metal parts requires specialized skills and

knowledge of the manufacturing techniques involved. The design

should take into account factors including raw material properties

and thickness, bending radius, manufacturing tolerance, and the

location of bends and holes. Computer-aided design (CAD) software

is usually applied to create detailed drawings that can be used to

guide the fabrication process.

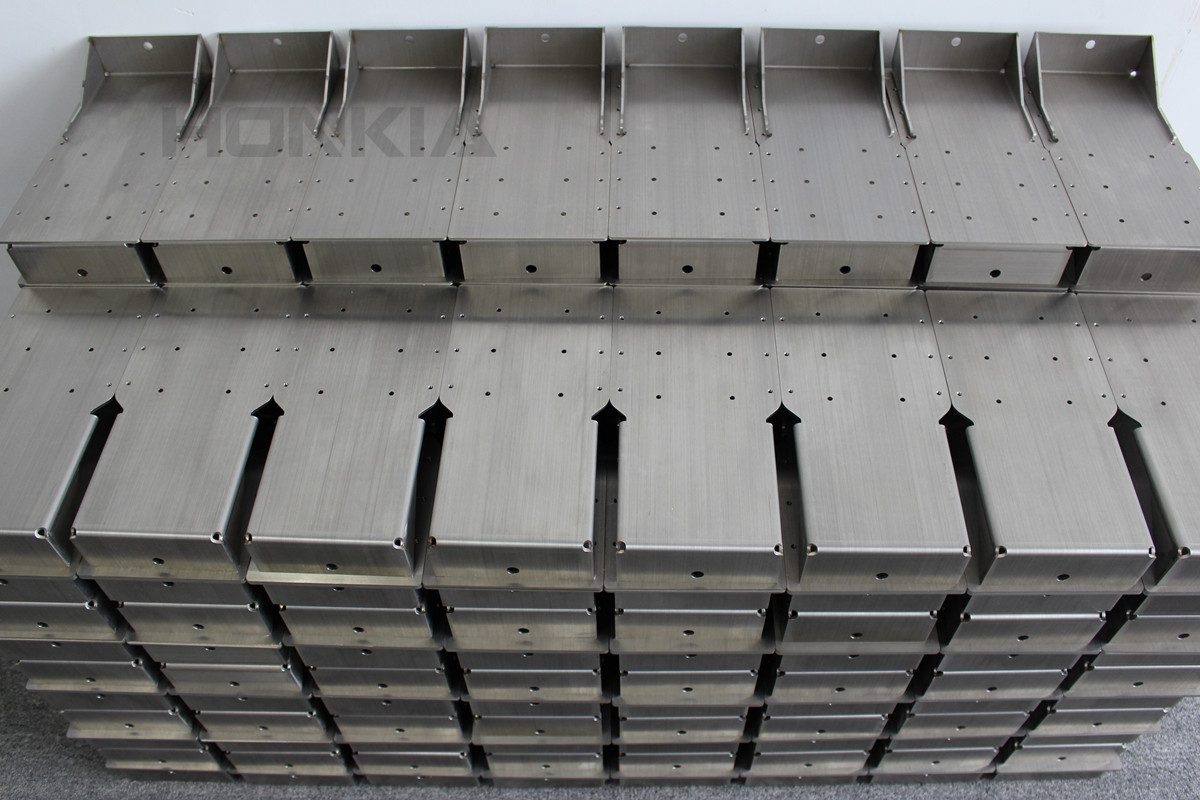

Bent Parts prior to Welding the Straight Corners. Different corner

angles could be bent well, our bending tolerance was around ± 0.1

mm. Welded and Cleaned Parts. All part surfaces were cleaned by

removing the laser cut and weld splatters as well as the grease and

residues.

Quality and Service are the true reasons that HONKIA survives and grows up in the market since our establishment. We saw some of our competitors are making money by playing around the quality

and then lose the market faster than we think. We do know that is not a sustainable business pattern.

We are a professional supplier. We know what we are doing. We keep a very stable quality level for years. Thanks to our professional production and technical team, our qualified products rate is 99.75% and we are constantly improving it, we hope our clients can get what they paid for.

Packaged Parts for Shipping. Since heavy weight, parts were delivered by sea to save shipping cost, which cost time about 25 days. We provide sheet metal fabrication service economically & quickly, surface finishings include: Painting, Powder Coating, Silk-screening, etc.

How does HONKIA compare to other suppliers on price?

Compared to other Chinese suppliers, we choose not to compete on price but to offer the high level of quality, rapid response, and professional results. That’s why some customers cooperate with us for many years, compared with the price, they need a reliable partner to avoid serious losses caused by annoying after-sales service or even the trouble of finding no one.

What if I am not completely satisfied with the parts I receive?

HONKIA will free remake or amend the returned parts that you are not completely satisfied, or refund the full arrived payment, though this is rarely happened in the past. Any disputes based on a subjective or unilateral determination shall be discussed and negotiated to reach a reasonable result. Our continuing business relies on earning your confidence in our ability to meet and exceed the reasonable expectations.