Shenzhen Honkia Prototype Co., Limited |

|

Reaction Injection Molding RIM Low Volume Large And Strong Parts Look Good And Work Great Cheap Price

Reaction Injection Molding (RIM) is an innovative manufacturing process used to produce the large and complex plastic parts with high flexibility, strength and durability. RIM involves the mixing of liquid bi-component polyurethanes in a mixer at certain amount ratio, then injecting the liquid mixture at room temperature and low pressure into mold cavity where the mixture reacts and cures into a solid part.

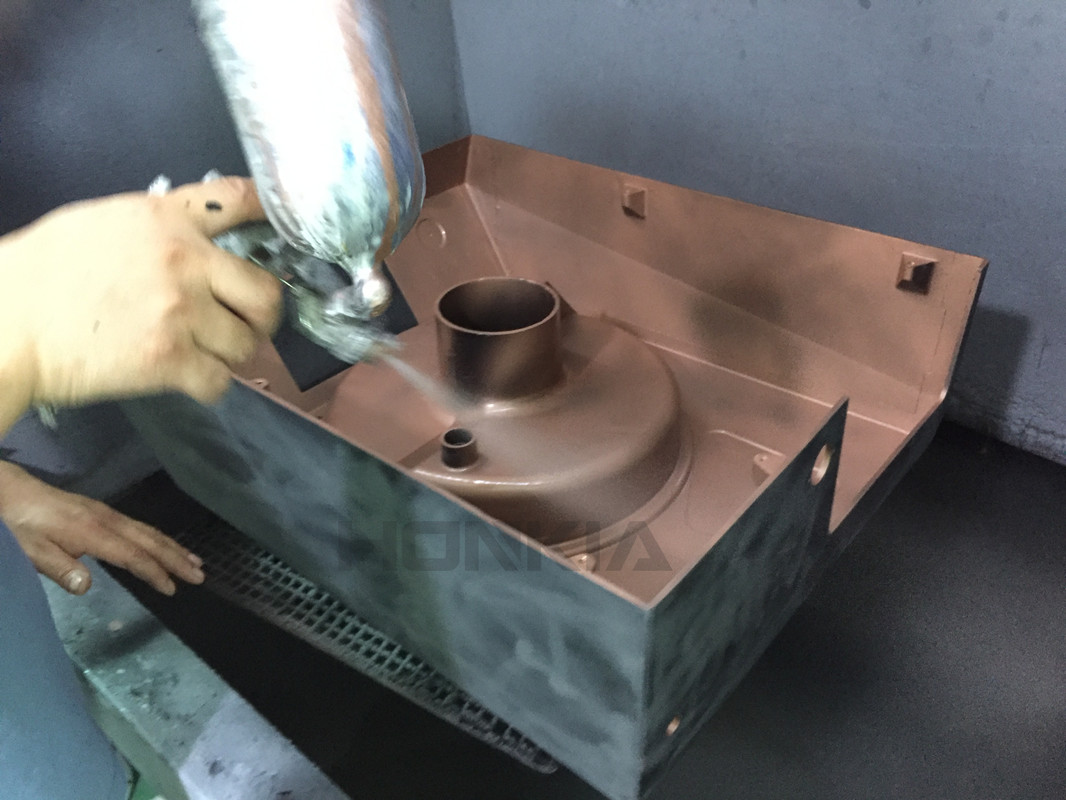

The extremely competitive tooling cost by our RIM process brought great advantage to low volume manufacturing this big enclosures economically and quickly. The finished enclosures had to not only perform as intended, but also look as pretty as possible by conductive and texture painting.

One advantage of RIM is its ability to produce large parts with a smooth and high-quality surface finishing, as well as the complex geometries and intricate details. Another advantage of RIM is its ability to produce parts with high strength and durability, which makes RIM parts ideal for applications that durability is a critical factor, such as industries of automotive, medical devices, aerospace, etc.

Our RIM tooling cost just a fraction of its relative steel mold used for mass production, making time usually 2 weeks instead of a couple of months. Reaction injection molding by room temperature and fairly low pressure brought the fairly low mold locking pressure as well as packing pressure.

Advantages of RIM Parts:

Thick and Various wall thickness for one part

Excellent mechanical properties

High flexibility, strength and durability

Good chemical resistance

Great impact resistance

Excellent dimensional stability

Cooling time of the reaction injection molded parts in the tooling

usually took half to one hour, and the tooling's silicone rubber

pieces as well. The first Reaction Injection Molded part. The injection molding

system would be adjusted when possible to get the best molded

quality.

We are respected in RIM industry in China, the RIM service we send out to global market are quick, economical and quality that are proven by the customers used our service, especially from automobile field. We look forward to doing more and better by our continuously improving RIM expertise and experience.

The deburred, sandblasted and sanded parts. Smooth and clean

surface, complete removal of demolding agent were indispensable for

painting.Each finished part was quality checked in fitting, tolerance and

appearance before shipping, the substandard ones were repaired or

remade.

RIM Parts Design Considerations:

When designing parts for RIM production, it's important to consider

factors such as size, structure, wall thickness, draft angles, and

gating. RIM parts can be designed with complex geometries and

intricate details, but it's important to ensure that the part

design is manufacturable and the tooling favors the design.

Quality and Service are the true reasons that HONKIA survives and grows up in the market since our establishment. We saw some of our competitors are making money by playing around the quality and then lose the market faster than we think. We do know that is not a sustainable business pattern.

We are a professional supplier. We know what we are doing. We keep a very stable quality level for years. Thanks to our professional production and technical team, our qualified products rate is 99.75% and we are constantly improving it, we hope our clients can get what they paid for.

We are respected in Reaction Injection Molding industry in China, the RIM service we send out to global market are quick, economical and quality that are proven by the customers used our service, especially from automobile field. We look forward to doing more and better by our continuously improving RIM expertise and experience.

How does HONKIA compare to other suppliers on price?

Compared to other Chinese suppliers, we choose not to compete on price but to offer the high level of quality, rapid response, and professional results. That’s why some customers cooperate with us for many years, compared with the price, they need a reliable partner to avoid serious losses caused by annoying after-sales service or even the trouble of finding no one.

What if I am not completely satisfied with the parts I receive?

HONKIA will free remake or amend the returned parts that you are not completely satisfied, or refund the full arrived payment, though this is rarely happened in the past. Any disputes based on a subjective or unilateral determination shall be discussed and negotiated to reach a reasonable result. Our continuing business relies on earning your confidence in our ability to meet and exceed the reasonable expectations.