Ironstone-Meca Industry |

|

Verified Suppliers

|

|

Adjustable New Type Mental Double Deep Pallet Rack System

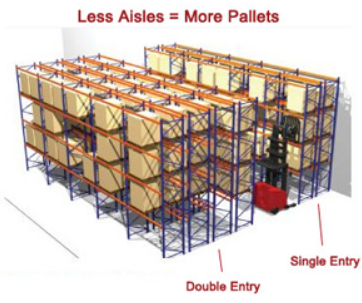

Double-deep pallet racking looks very similar to selective racking but is stored two units deep instead of one. A specialized pantograph reach truck with scissor fork extensions is typically used to store and retrieve pallets on the inner pallet position. Double Deep pallet Racking is best suited for SKUs with several pallets of inventory that are not highly perishable and do not require FIFO inventory rotation.

| Name | Double Deep Pallet racking | Material | High Strength Steel-/American Standard Steel |

| Beam levels | 2~15 tiers per bay rack | Color | (RAL Code) Green, Orange, Blue, Yellow, Etc. |

| Upright Frame Height | 2500mm~15000mm | Weight Capacity | 500~3000kg per level |

| Beam Width | 1000mm~3900mm | Frame Depth | 700mm~1500mm |

| Finish | Epoxy Powder Coated for corrosion prevention | ||

| Usage | Cargos Storage | ||

| Package | Plastic stretch film, corrugated paper, Cartons, wooden bars, crates, and metal strips, etc. | ||

| Accessories | Bolts and nuts, Upright protectors, decks, etc. | ||

| Certification | RMI/AS4084-2012 /CE/ ISO9001 | ||

| Delivery time | 7~25 days as per order quantity | ||

| Assemble & installation | Detailed assembly instructions are available as well as dispatching installation engineer for project installation at the site. | ||

Characteristic

♦ Designed for last-in, first-out (LIFO) inventory management.

♦ Medium stock flow, providing 50% optionality.

♦ A special forklift is needed because it needs cross two rows to pick up the products.

♦ In a warehouse of the same area, compared with selective pallet rack, the parallel four sets of shelves reduce the aisle position, which has high space utilization rate, and each storage shelf can store more than twice the pallets.

♦ If it is planned to access the products in the rear row, only after removing or shifting the products in the front row could access them. It is difficult to achieve first-in, first-out inventory management. In order to improve the utilization rate of the warehouse, the general inventory is stored on the back shelves first and then on the front shelves.

♦ In the shipment of products, it is better to put the front and rear products out at a time. If not, the inventory utilization rate or warehouse operation efficiency may be affected.

Advantages

► Structured with beam and upright frame, could be satisfied with various loads.

► Adjustable height of frame can meet the needs of cargo storage.

►Simple structure makes it flexible to add other accessories according to the characteristic of the cargo.

► Mechanical inventory has higher selection efficiency and lower investment cost.