Ironstone-Meca Industry |

|

Verified Suppliers

|

|

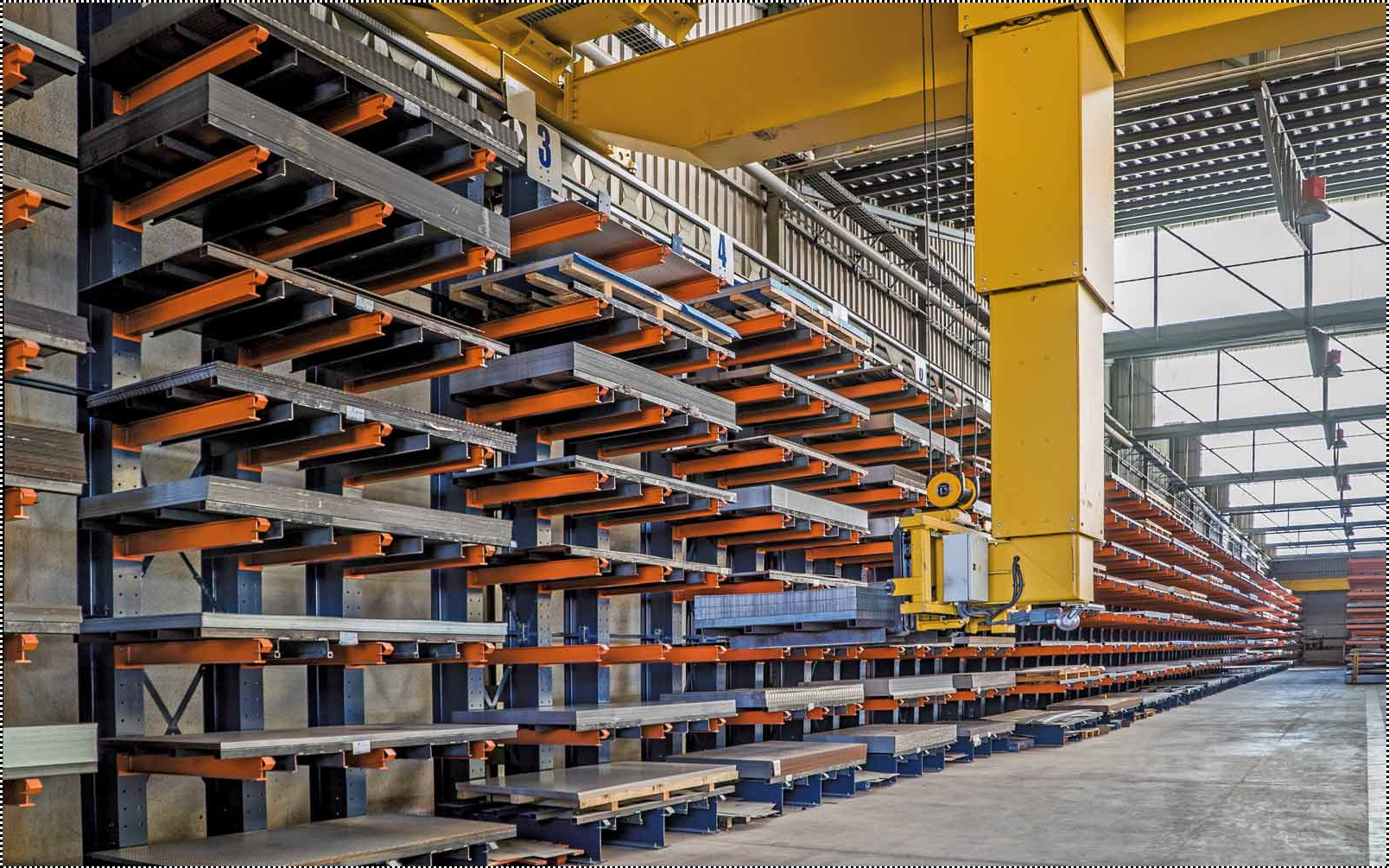

Customized Sizes Of Cantilever Racks For Different Load Capacity Product Storage

Different Types of Cantivlever Rack

Cantilever rack, having different loading capacity, can be divided into light duty, medium-duty and heavy duty cantilever.

Light duty cantilever racking, usually made with angle steel, can store light loads with weight less than 250kg.

Medium duty cantilever racks, usually made from roll-formed gauge steel, are the most popular one in cantilever systems. Using different gauges of steels means different loading capacity, which you can customize to adjust to different requirement.

Heavy duty cantilever racking, are usually constructed with structural steels having very high loading capacity. Normally, cantilever racks made from structural steel can hold more heavy loads than roll-formed.

Specifications of Cantilever Rack

| Name | Cantilever rack | Material | High Strength Steel |

| Arm levels | 2~10 tiers per bay | Color | (RAL Code) Green, Orange, Blue, Yellow, Etc. |

| Upright Frame Height | 2500mm~10000mm | Weight Capacity | 200~1200kg per arm |

| Arm Length | 800mm~1500mm | Frame Distance | 500mm~1600mm |

| Finish | Epoxy Powder Coated for Corrosion Prevention | ||

| Usage | Long and Bulky Cargoes Storage | ||

| Package | Plastic stretch film, Corrugated paper, Cartons, Wooden bars, Crates, Metal strips, etc. | ||

| Accessories | Bolts and nuts, upright protectors, decks, etc. | ||

| Certification | RMI/AS4084-2012 /CE/ ISO9001 | ||

| Delivery Time | 7~25 days as per order quantity | ||

| Assemble & Installation | Detailed assembly instructions or dispatching installation engineer for project installing at site. | ||

For the loading capacity, there’s something that worth your attention.

1. Upright capacity vs Arm capacity

In a cantilever racking system, the main components that bear weight are the upright column and the arms. So we get the corresponding terms: upright capacity and arm capacity. The two parts, as well as the rack’s configuration, all joined together to decide the total loading capacity of a cantilever rack. You don’t need to know the complicated calculation formular, but during the process of using, you must guarantee both upright capacity and arm capacity are fully qualified for safety concern.

2. Uniform Distributed Load

The loading capacity we talked before all based on the calculation of the UDL(uniform distributed load), which means loads are evenly distributed on the arms. So during practical operation, uneven placed loads may cause pointed loads resulting unexpected results.

How to choose your own cantilever ?

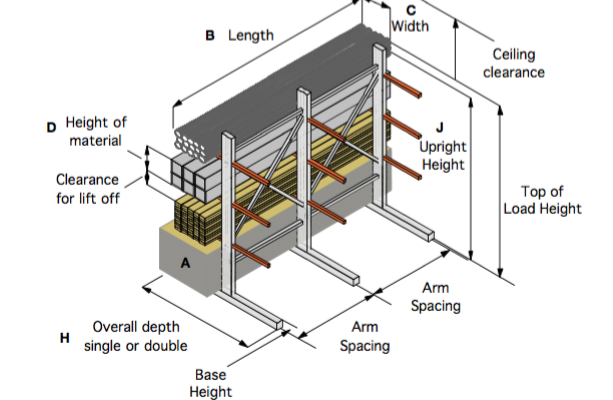

If you decided to choose the cantilever racking system for your warehouse, some parameters you should know.

Parameters That Matter

1. Loads

When choosing the proper cantilever racking system, make sure you familiar with your products and measure the sizes of your loads accurately.(eg. length, height, width, weight)

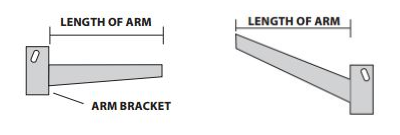

2. Arms

♦ The number of arms are decided by the height of the upright columns and the loads.

♦ The length of the arm is up to the depth and weight of the loads, the former should always be longer than the latter.

♦ The distance between two adjacent arms is taken up by the height of the load and the required clearance for handling.

♦ The arm capacity is determined by the overall weight of a loading level and number of arms that carry the weight.

♦ The arm spacing should be decided by considering the length of the load and the number of arms that hold it.

♦ Usually, the load should overhang the end arms by one-half the distance from upright center-line to upright center-line.

♦ Unreasonable arm spacing and overhang of loads may lead to serious accident.

3. Uprights

♦ The height of the uprights is affected by the height of the ceiling and the materials handling equipment you are using.

♦ The upright capacity is based on several factors: the arm capacity, the number of the arms and the number of uprights.

All in all, choosing the right cantilever racking system with proper sizes and loading capacity will help you improve your space utilization and material handling efficiency leading to a maximization of your profits.

However, if you want to have a perfect cantilever racking system that best suits to your warehouse while don’t want to bother yourself with all these troubles of learning and researching, you can always contact us for your personal consultant. A whole package of excellent services including design, manufacture, installation and maintenance will be delivered to you with reasonable price.