Xinxiang HUAYIN Renewable Energy Equipment Co., Ltd |

|

Tyre To Oil Waste Tyre Pyrolysis Machines 3 Ton Pyrolysis Unit Exported To Australia

Product information

1. Function: convert waste tire to fuel oil, carbon black, steel wire, and combustible gas.

2. Capacity from 1 ton-15ton capacity per batch.

3. Fast installation design & Bulk type design &Container design

4. Different designs for the dedusting system to meet the emission requirements of different countries.

5. Large condensing area ensures high oil yield.

Input raw material

The applicable waste raw material includes various kinds of waste tires, car tires, bicycle tires, motorcycle tires, OTR tires, etc.

Various kinds of plastic waste, like PP, PE, PS, ABS, PMMA, etc.

Output product usage

1. Fuel oil (40-45%): Widely used as fuel oil in industries such as steel and iron factories, ceramics or heavy oil generators, cement factories, and boiler heating, etc. Or being refined into non-standard diesel for use in trucks, tractors, etc.

2. Carbon black(30%): Be pressed into pellets for use in industrial heating

3. Steel wires(10%): Sold or reprocessed.

4. Combustible gas(10%-15%): Can be recycled and used during production as fuel.

Specification

| Model | HY-05 | HY-08 | HY-10 | HY-15 |

| Raw material | Waste rubbers/tyres/plastic | |||

| Output product | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |||

| Daily Handling capacity | 5 tons | 8 tons | 10 tons | 12 tons |

| Machine dimension(mm) | D2200*L5500 | D2600*L6600 | D2800*L6600 | D2800*L8000 |

| Landing Area | 200m2 | 250m2 | 300m2 | 350m2 |

| Working pressure | Normal pressure | |||

| Main engine rotating speed | 0.4R /min | |||

| Power | 15KWH | |||

| Cooling Mode | Circle Water | |||

| Heating Mode | Direct | |||

| Oil Yield | 40%-50% | |||

| Noise dB (A) | <=85 | |||

| Working Mode | Batch type | |||

Our advantage

1. High automation: Loading used tires/plastic into the pyrolysis reactor with 50ton hydraulic pressure, so the auto feeder can help you save labor and load more waste raw material, compared with manual feeding, the automatic feeder is more efficient.

2. 100% safety: The pyrolysis reactor is made of Q245R/Q345R boilerplate, which is high pressure and high-temperature resistance that ensure its longer service life. Adding perfect hot seal technology to ensure operation safely.

3. Environmental friendly: Flue gas is purified by ceramic packing dedusting device, finally no black smoke emitted.

4. High efficiency discharging device: Discharge carbon black from pyrolysis reactor after the production is finished in a sealed condition, no pollution and saves labor and time.

5. Strictly quality control. All of the steel plates are purchased from China's famous company " Anyang Iron and Steel Co., Ltd ", and the raw material inspection certificate can be provided to customers. For each set of machines, we will do ultrasonic nondestructive testing, and automatic submerged welding technology to ensure the machine quality.

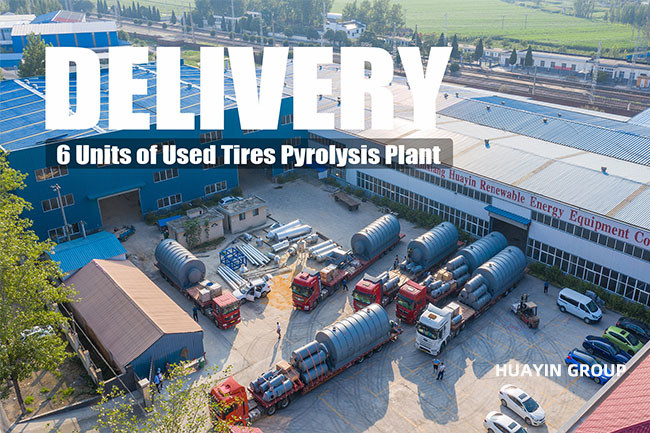

Packing and shipping

All goods are packed with exported standards packages to make sure no damage during transportation.

Delivery time is 15 working days after receiving the deposit.

Our services

1. One-stop solution. We have more than 20 years of rich experience

in manufacturing waste pyrolysis plants. We pay more attention to

customer experience and customer satisfaction. As long as you need

it, we are able to provide you with a better quality complete

production line.

2. We have our own factory and trading company, no middlemen, more

cost-effective, and it is more convenient for you to replace

related parts, as long as there is a problem, we can provide a

solution immediately, product quality is guaranteed.

3. We promise that our plants are efficient and have a long service

life to ensure that you can quickly produce in batches.

4. Delivery time is 15-25 days.

5. We can send engineers on-site to guide installation and train

your workers.

6. One-year warranty, lifelong maintenance of the equipment, providing professional use guidance services.

For more details, welcome contact us!