Guangzhou Nanya Pulp Molding Equipment Co., Ltd. |

|

Verified Suppliers

|

Molded Fibre 30 Holes e Egg Tray Carton Making Machine With Dryer

Description

1. By changing moulds, the same machines can make different products, like egg carton, egg tray, fruit tray, industrial package items and etc.

2. This production line consists of a pulping system, a reciprocatting forming machine, a single layer drying line, hot press system, vacuum system, air compressor system and auxiliary equipments.

3. Our machinery adopts high quality electronic devices and pneumatic components, high performance and long service life.

Specifications:

Model type | EW1200-A |

Capacity | 1400pcs/hour |

Workshop requirement | 350 m2 |

Electricity consumption | ~70kw |

Electricity Installed | 100kw |

Material consumption | 80~100kg/h |

Water consumption | 300~400kg/h |

Worker requirement | 4~5 person |

Container requirement for shipment | 4 x 40HQ |

Forming machine (reciprocating type) | plate size 1600*800mm 6pcs/time |

Drying line | 26x2.2x2.4m 1-Layer |

| Dryer Fuel | Natural Gas / LPG / Diesel / Heavy Oil / Steam / Wood / Coal |

Advantages

1. Different capacity production for choice;

2. Easy to install and operate;

3. Rugged construction;

4. Heat resistance;

5. Competitive price;

6. Green: No waste paper emission;

Working Theory:

YOUTUBE Video Links

https://www.youtube.com/watch?v=nEtQndYddGU&t=109s

Applications:

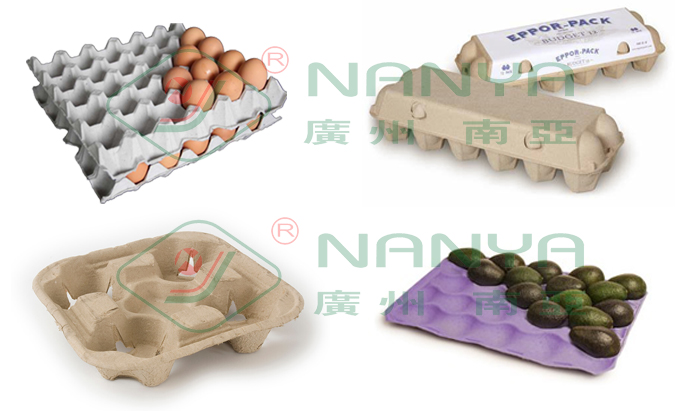

Egg tray | 20,30,40packed egg tray… quail egg tray |

Egg carton | 6, 10,12,15,18,24 packed egg carton… |

Agricultural products | Fruit tray, seeding cup |

Cup salver | 2, 4 cup holder |

Disposable Medical Care Products | Bedpan, kinkey tray, female urinal… |

packages | Shoe tree, industrial package… |

| |

Competitive Advantages:

FAQ

Q: What does your factory produce?

A: We make all kinds of pulp molding machine including egg tray machine, egg box machine, fruit tray machine, bottle tray machine, paper shoe stretcher machine, seedling tray machine, industrial inner package machine etc..

Q: What about your standard delivery date?

A; for different capacity, the delivery date is different, for the model type, the delivery date is 60 days.

Q: Do you have guarantee on your products?

A: We guarantee 12 months for the maintenance and repair of the forming machine.