60mm two phase hybrid stepper motor NEMA14 Bi-Polar 1.8 step motor

Product description

- Online testing of technical parameters to ensure the consistency of

data product parameters

- The material is selected from well-known manufacturers at home and

abroad. The advantages are light weight, good heat dissipation

performance, good thermal conductivity, die-casting, good

plasticity, higher elongation than iron, low noise, good motion

stability, the disadvantages are high price, low hardness

- Automatic assembly line

- Automatic assembly line, improve production efficiency, low cost

without human operation, one line down intelligent mechanical

automatic assembly

- Strictly control the production of parts to improve the quality of

parts

- Automatic machine operation, stable automatic work, high processing

efficiency.

- Mechanical size 100% meet the requirements, to ensure that there is

no greater error in the use process

Specifications of hybrid stepper motor

| Mode No | PST60H286-4P30 | PST60H286-4L40 | PST60H286-4L50 |

| Holding Torque | 3N.m | 3N.m | 3N.m |

| Related Current | 3A/Phase | 4A/Phase | 5A/Phase |

| Resistance | 1.3Ω/Phase | 0.78Ω /Phase | 0.43Ω/Phase |

| Inductance | 5MH/Phase | 2.7MH/Phase | 1.7MH/Phase |

| Inertia | 690g.cm2 | 690g.cm2 | 690 g.cm2 |

| Weight | 1.3kgs | 1.3kgs | 1.3kgs |

| Length | 85mm | 85m | 85mm |

| Connection | P | P | L

|

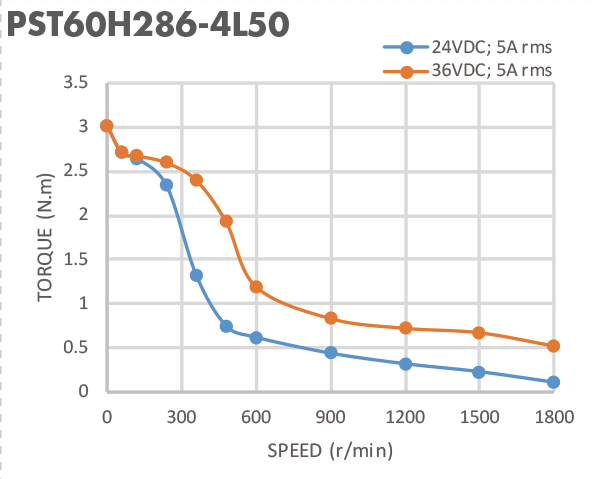

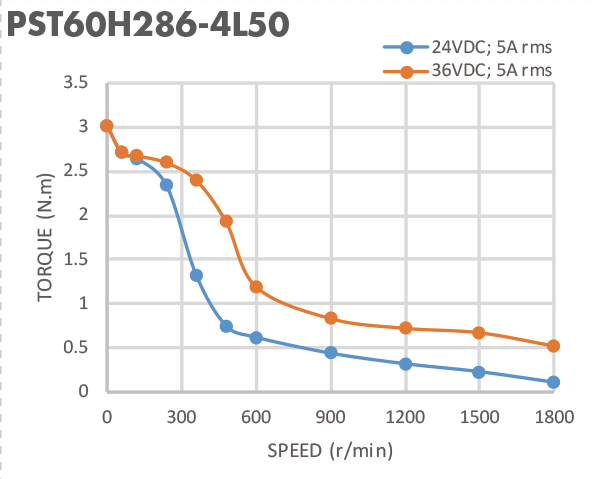

Speed/Torque Characteristics(Reference Value)

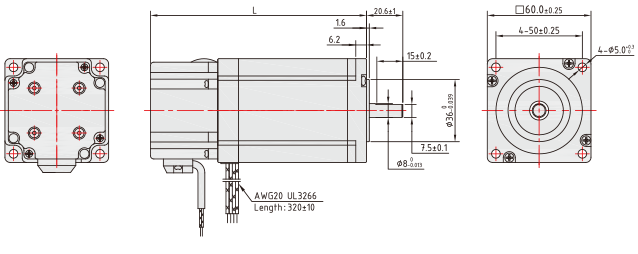

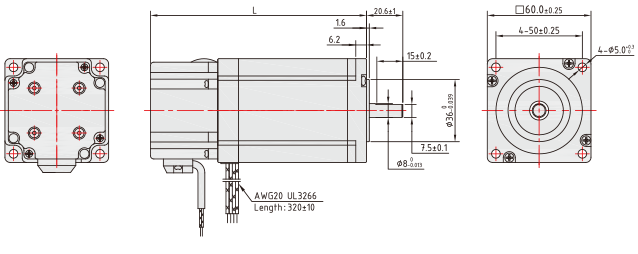

Outline(Unit:mm)

Note

The winding on this article is a 4 Wire Bipolar.

0.9° and 1.8° Hybrid Stepper Motors

- 1.8° Step Angle,The motors are directly compatible with the stepper

motor drive boards and also drive either motor (if required) in the

half step mode i.e. 0.9° per step resulting in higher resolution,

greater performance stability and faster stepping rates. Direction,

velocity, acceleration/deceleration can be controlled by a stepper

motor controller.,Applying the correct electrical pulse sequence to

the windings of the stepper motor results in a 1.8° step angle

rotation of the spindle (i.e. 200 steps per revolution). When

correctly loaded and driven these motors will produce discrete

output steps. The number of steps and speed of rotation are

determined by the number of pulses and frequency of the input

signal. This provides an ideal method for speed and position

control. The motors are directly compatible with stepper motor

drive boards.,

Why choose stepper motor

- While these applications are the most common, they’re a fraction of

what stepper motors can be used for. Generally speaking, any

application that requires highly accurate positioning, speed

control, and low speed torque can benefit from the use of stepper

motors.

- While servo motors have their place in industry as well as numerous

advantages of their own, stepper motors are an ideal solution in

many applications.

- Stepper motors are a robust motion control technology and can be

found inside of many common machines and equipment. To learn more,

browse stepper motors at Prostepper from the world’s leading suppliers.