Active Member

|

[China]

Address: Block 11, International E-Commerce Logistic Center, PingHu Street, LongGang Distric, ShenZhen City

Contact name:Steven

Witgain Technology Ltd |

|

PCB Specifications:

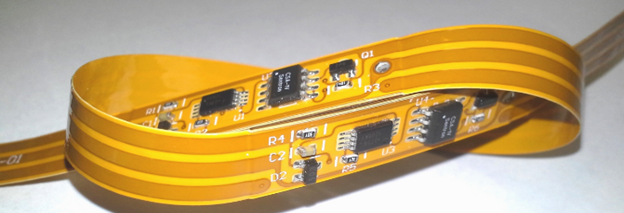

Layer Count: 4Layer Rigid-Flex PCB

Board Thickness: 1.2MM

Material: FR4 +PI

Structure: L1&L4 Rigid Layer, L2-L3 Flex Layer

Min Hole: 0.3MM

Min Line: 6/6 Mil

Hole: L1-L4

Solder Mask: Green

Surface Treatment: ENIG

Application: Industrial Control

Capabilities:

| Item | Capability |

| Layer Count | 1-24 Layers |

| Board Thickness | 0.1mm-6.0mm |

| Finished Board Max Size | 700mm* 800mm |

| Finished Board Thickness Tolerance | +/-10% +/-0.1(<1.0mm) |

| Warp | <0.7% |

| Major CCL Brand | KB/NanYa/LTEQ/ShengYi/Rogers Etc |

| Material Type | FR4,CEM-1,CEM-3,Aluminum,Copper,Ceramic, PI, PET |

| Drill Hole Diameter | 0.1mm-6.5mm |

| Out Layer Copper Thickness | 1/20Z-8OZ ; |

| Inner Layer Copper Thickness | 1/3OZ-6OZ |

| Aspect Ratio | 10:1 |

| PTH Hole Tolerance | +/-3mil |

| NPTH Hole Tolerance | +/-1mil |

| Copper Thickness Of PTH Wall | >10mil(25um) |

| Line Width And Space | 2/2mil |

| Min Solder Mask Bridge | 2.5mil |

| Solder Mask Alignment Tolerance | +/-2mil |

| Dimension Tolerance | +/-4mil |

| Max Gold Thickness | 200u'(0.2mil) |

| Thermal Shock | 288C, 10s, 3 Times |

| Impedance Contro | +/-10% |

| LTest Capability | PAD Size Min 0.1mm |

| Min BGA | 7mil |

| Surface Treatment | OSP, ENIG, HASL, Plating Gold, Carbon Oil,Peelable |

FAQ:

Question: What are Flexible Printed Circuit Boards?

Answer:

A Flexible Printed Circuit Board (PCB) is a board that can be bent to conform to a desired shape during its application. The board can be bent or twisted without damaging the circuit. The substrate material used to build the PCB is responsible for its flexibility. Polyamide, PEEK (Polyether ether ketone) or a transparent conductive polyester film are common substrates used to make flexible PCBs.

The layers of a Flex PCB are more or less the same as a Rigid PCB, with the addition of an overlay, or coverlay i.e. a lamination process used to encapsulate and protect the external circuitry of a flex circuit. This is similar to the solder mask layer in a rigid PCB. The coverlay film is a polyimide film which is coated with a thermoset adhesive. It protects the flexible circuit from damage. The coverlay is optional, but most flexible PCBs do use this.

The fabrication of flexible PCBs does cost more than rigid PCBs, however they have a number of advantages in certain applications and thus the cost can be justified. For example, they can replace bulky wiring in Satellites where space and weight are the main constraints for the designers. They are also in LED Strips, consumer electronics and a number of other applications.

Other advantages of flexible Printed circuit boards are that they are lighter than rigid boards and have improved resistance to vibrations and movement so are often used in transportation applications.