TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

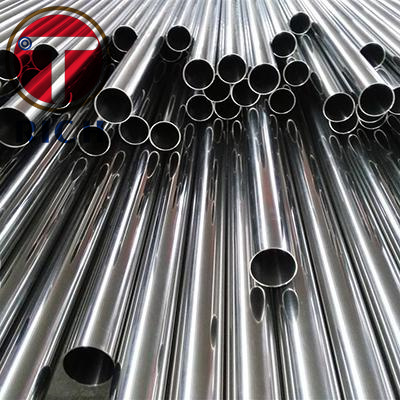

ASTM A312 TP304 Seamless Welded Stainless Pipe for Fluid Gas Transport Hydraulic Pressure

TORICH is a Professional Manufacturer of ASTM A312 TP304 Seamless Welded Stainless Pipe, which is for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

We can manacture stainless steel tubes based on the following

technical standard:

ASTM A213,ASTM A312,ASTM A511,ASTM A269,ASTM A249,ASTM A358

The Stainless Steel Grade can cover the following:

ASTM A213 TP304 TP304L TP304H TP310S TP316 TP316L TP316H TP317

TP347

ASTM A312 TP304H TP309H TP310H TP316H TP321H TP347H TP348H TP304

TP309S TP310S TP316 TP321 TP347 TP348

ASTM A511 MT304, MT304L, MT309, MT309S, MT310S, MT316, MT316L, MT317,MT321, MT347

ASTM A269 TP304 TP304L TP321 TP347 TP316 TP316L TP348 TP317

ASTM A249 TP304 TP304L TP321 TP347 TP316 TP316L TP348 TP317

ASTM A358 TP304

| Producsts Name | ASTM A312 TP304 Seamless Welded Stainless Pipe for Fluid Gas Transport Hydraulic Pressure |

| Technical Standard | ASTM A312 TP304 Seamless Welded Stainless Pipe |

| Steel Grade/Steel Numbe | TP304H TP309H TP310H TP316H TP321H TP347H TP348H TP304 TP309S TP310S TP316 TP321 TP347 TP348 |

| Size Range | OD: 6mm-219mm WT: 1-35mm Length: max 12000mm Cutting Length: available according to customer's requirement. |

| Delivery Condition | Bright Annealing. Pickling and Solution Heat Treatment. |

| Surface Treatment/Surface Condition | Bright Surface. Dull Surface. Polish Surface. |

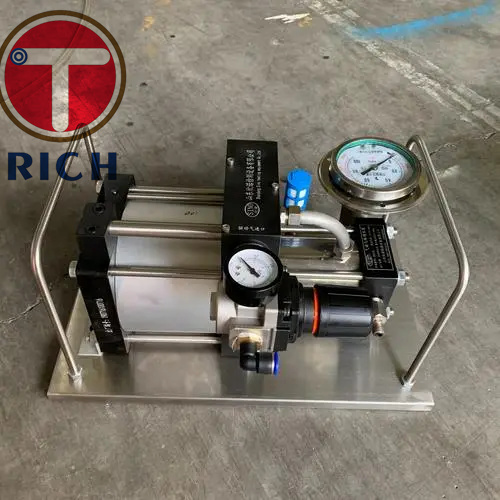

| Tube Inspection | 100% Dimensional Check 100% Eddy Current Test (ETD) 100% Ultrasonic Test (UTD Mechanical Properties Inspection, Internal Lab test report or Third Party Inspection Report. |

| Inspection Istrument | Outside micrometer, wall thickness micrometer, inside dial gauge, vernier caliper, tensile testing machine, hardness tester, eddy current flaw detector, metallographic analyzer, surface roughness meter |

| Tube Application | Fluid and Gas Transport Industry Hydraulic Pressure |

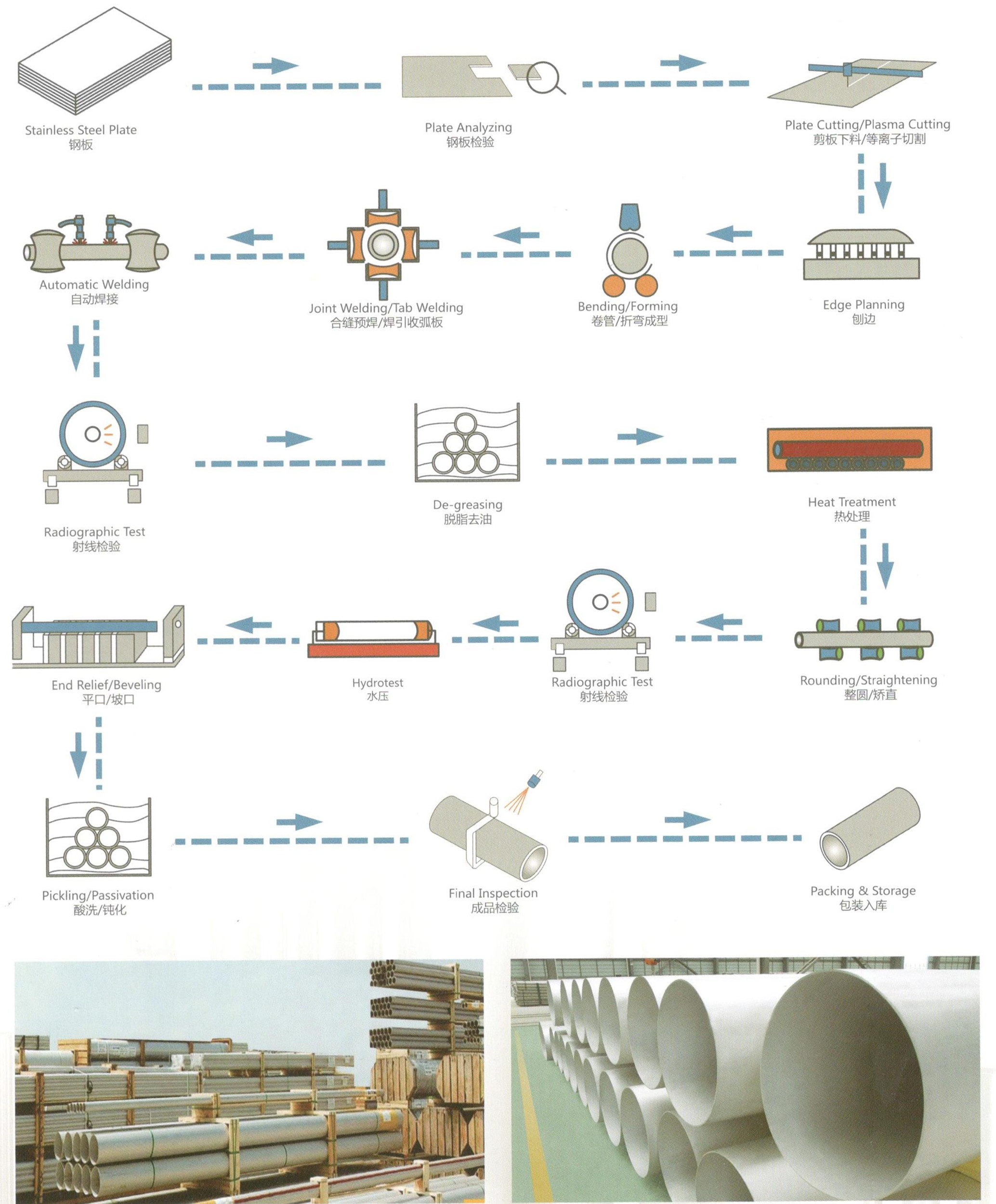

| Production Process | Round steel warehousing → round steel inspection → round steel sawing → central hole drilling → perforation → pickling → cold drawing or cold rolling (finish rolling) → annealing → straightening → head and tail cutting → finished product inspection → packaging → delivery |

Chemical composition for ASTM A312 TP304 Seamless Welded Stainless Pipe

| Material | C | Mn | P | S | Si |

| TP321 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP321H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP347H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP304L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP304H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP309H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP309S | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP310H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP316L | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP316H | 0.040-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP347 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP348 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 |

| TP348H | 0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 |

Materials and Manufacture ASTM A312 TP304 Seamless Welded Stainless Pipe

Manufacture:

The pipe shall be manufactured by one of following processes

Seamless pipe shall be made by a process that does not involve welding at any stage of production.

Welded pipe shall be made using an automatic welding process with no addition of filler metal during the welding process.

Heavily cold-worked pipe shall be made by applying cold working of not les than 35% reduction in thickness of both wall and weld to a welded pipe prior to the final anneal.No filler shall be 100% radiographically inspected in accordance with the requirements of ASTM Boiler and Pressure Vessel Code,Section VII,Division 1,lastest revision.

Welded pipe and HCW pipe of NPS 14 and smaller shall have a single longitudinal weld.Welded pipe and HCW pipe of a size larger than NPS 14 shall have a single longitudinal weld or shall be produced by forming and welding two longitudinal sections of flat stock when approved by the purchaser.All weld tests,examinations,inspections,or treatments shall be performed on each weld seam.

At the option of the manufacturer,pipe shall be either hot finished or cold finished.

The pipe shall be free of scale and contaminating exogenous iron particles.Pickling,blast ing,or surface finishing is not mandatory when pipe is bright annealed.The purchaser is permitted to require that a passivating treatment be applied to the finished pipe.

Heat Treatment-All pipe shall be furnished in the heat -treated condition in accordance with the requirements of Table2.Alternatively,for seamless pipe,immediately following hot forming while the temperature,pipes may be individually quenched in water or rapidly cooled by other means.

Prodution Pictures for ASTM A312 TP304 Seamless Welded Stainless Pipe

Products Application of ASTM A312 TP304 Seamless Welded Stainless Pipe

Production Process for ASTM A312 TP304 Seamless Welded Stainless Pipe

Production Workshop for ASTM A312 TP304 Seamless Welded Stainless Pipe

Delivery and Packing of ASTM A312 TP304 Seamless Welded Stainless Pipe

FAQ

1. who are we?

TORICH is not only professional manufacturer and exporter, but also

international marketing

and sales company in the field of steel tubes from China. Our factory was established in 1997

with the name of Haiyan Sanxin Steel Pipe Co., Ltd. Our technicians are equipped with great

engineering experience in steel pipe industry for more than 22 years, they have great comma-

nd of production technology for Cold Drawing and Cold Rolling, as well as heat treatment and

inspection. So we have a strong technician team and manufacturing capability.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Stainless Steel/Carbon Steel/AlloySteel,Titanium,Copper/Brass,etc.

4. what services can we provide?

Accepted Delivery Terms:

FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Deliv-

ery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit

Card,PayPal,Western Union,Cash,Escrow;

Language

Spoken:English,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian