NTT Mould Co., Ltd. |

|

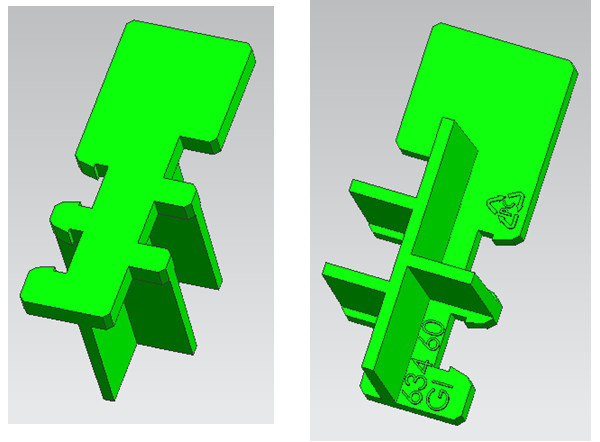

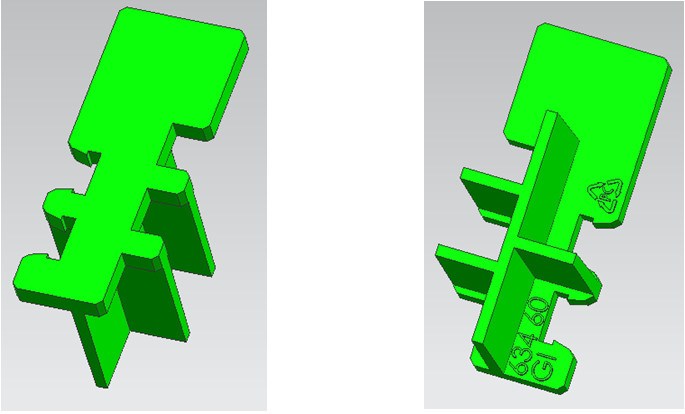

Submarine Gate Two Shot Injection Molding High Precise 4 Cavities Polycarbonate Parts

Project Details:

| Mold Number: | NTT-1803-44-2 |

| Part No.: | SG1644 |

| Core and Cavity: | 1.2344 |

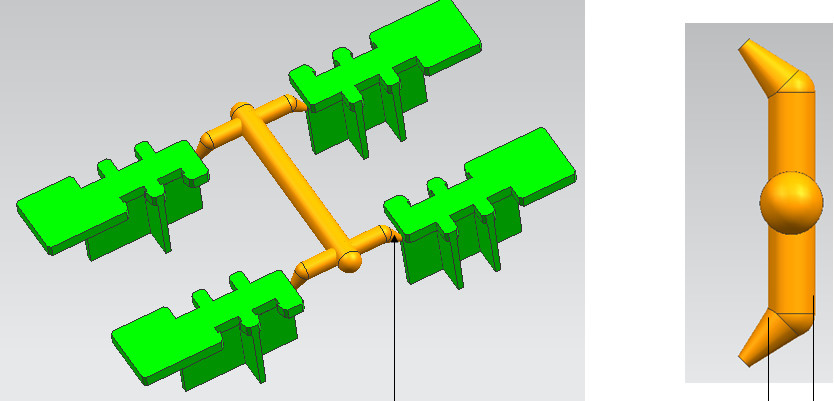

| Injection System: | Cold runner/ Sub gate |

| Molding Machine: | 80 T |

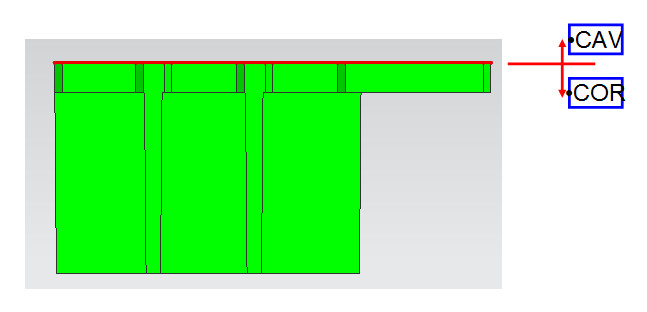

| Cavity Numbers: | 4 |

| Surface Finish: | Polish |

| Mould Life: | 500,000 Cycles |

| Resin: | Lexan 940 f1-PC-V0, UL |

| Shrinkage: | 1.005 |

| Color of Samples: | Black |

| Mold Lead Time: | 4.5 weeks |

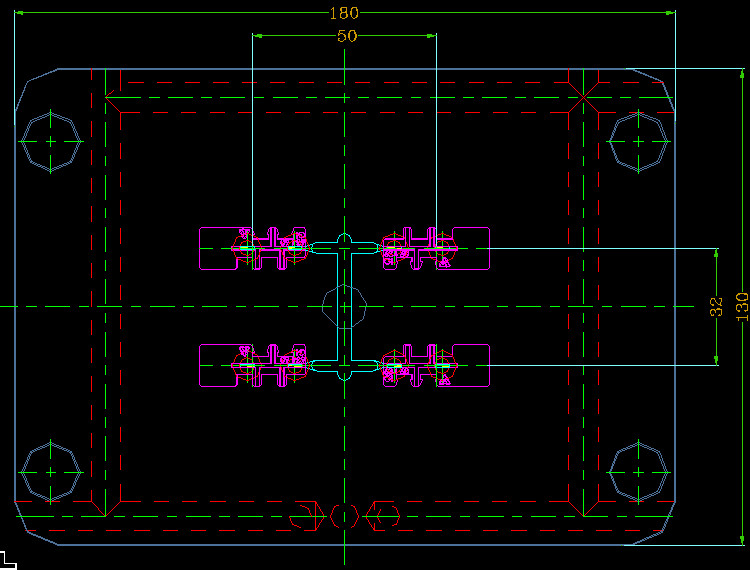

| Tool Dimensions: | 180x230x151 mm |

| Mold Weight: | 114 kg |

| Mold Maker: | NTT Mould Co. LTD |

| Place of Origin: | Shenzhen, China |

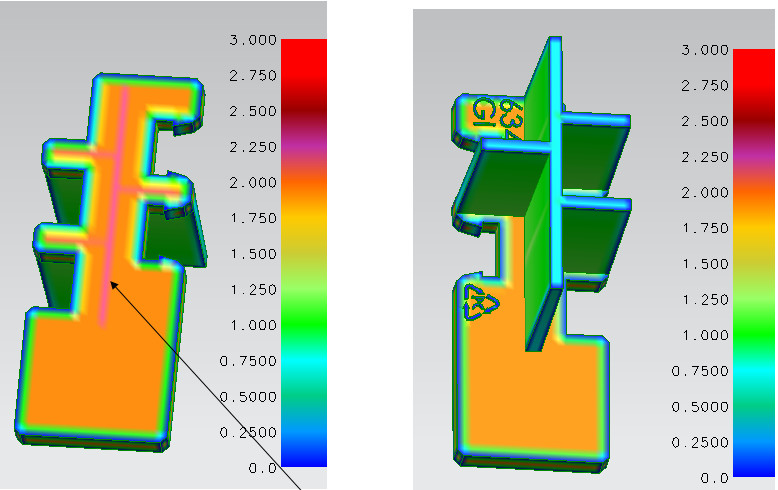

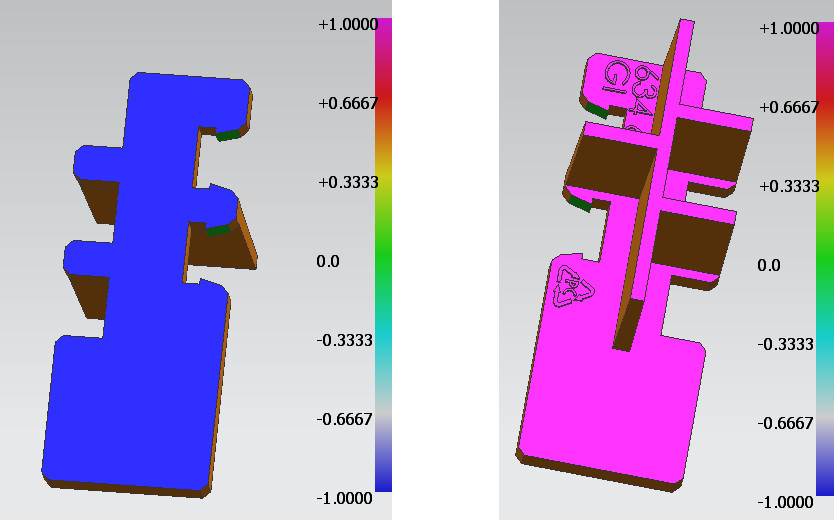

Thickness:

Draft Angle:

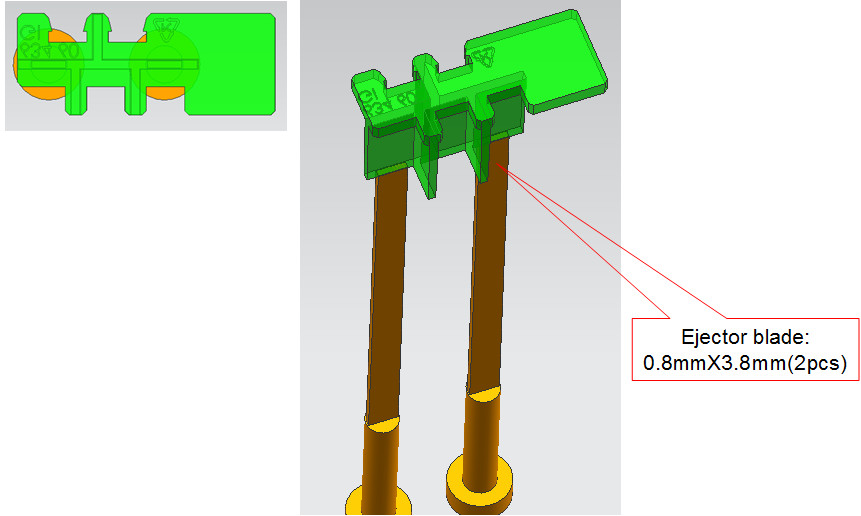

Gate:

Sub Gate 4mm

Parting Line:

Ejector Pin Mark.:

Finish:

Cavity surface: VDI3400 27 Core Surface: Polishing

Layout:

About NTT:

Main Business: high-quality plastic injection molds, injection molding, & part assemblies.

NTT uses the latest CAD design software like UG, Solidworks, Pro-E and AutoCAD for the mold design. We also have the latest precision equipment like high speed CNC machining centers, CNC precision WEDM wire cutters, mirror EDM and so on.

Our Competitive Advantages:

1) Quickly respone and complete understanding

2) The most competitive and reasonable price

3) Short delivery time and prompt delivery

4) Well and High Quality Control

5) Customer's Designs and Logos are welcome

6) In a variety of designs

7) Small order accepted

8) OEM acceptable

How NTT follow your project?

◆ RFQ

◆ Quotation

◆ PO

◆ DFM

◆ Mold Design

◆ Design Approved

◆ Steel Ordering

◆ Machining

◆ Mold Trial

◆ Sample Approved

◆ Texture

◆ Delivery

Every week, we will send you weekly report with components (electrode, cavity, core, mold base) picture to show you the process of the project.

When we make T1 samples, we will make a video to you, and also send samples with molding report for your approval.

If possible, we would like to invite someone you to pay a visit to our facility, so that you might be better to understand our capabilities to be of assistance to your company.

You may viisit our website to view more molds and products.

Looking forward to having a good start for our reliable

cooperation!