NTT Mould Co., Ltd. |

|

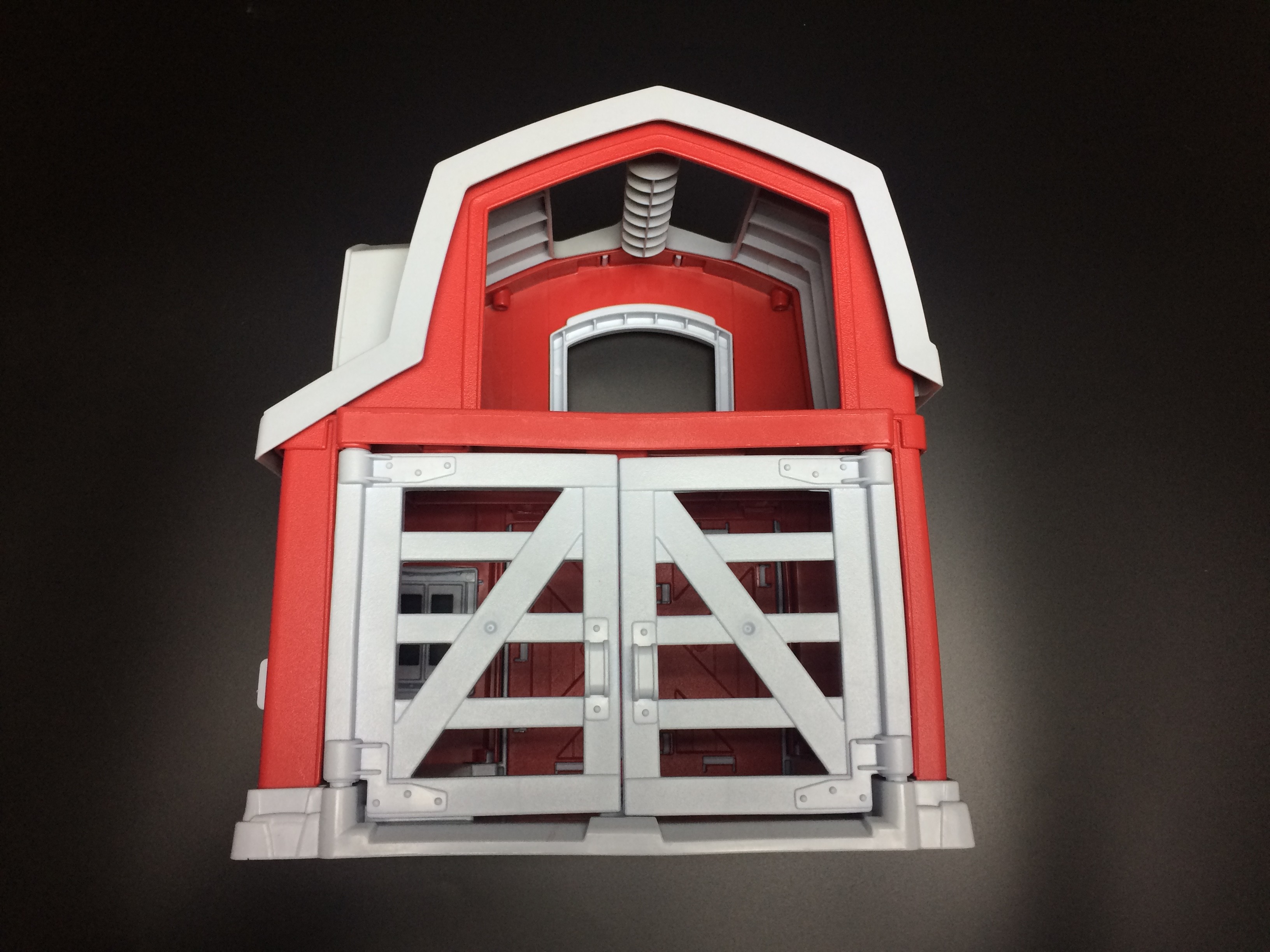

OEM Plastic Injection Mould Maker Red And Grey Color Stable Toys For Kids

Company General View:

1. High quality & precision injection molds: Hot runner mold, over mold, two-shot mold, unscrewing mold, multi-cavity mold, etc.

2. Injection molding, part assemblies

3. Value-adding services: Die casting, Painting, Pad-printing, Silk-Screen Printing, Hot Stamping, Plating, Ultrasonic Welding, Automation.

4. Industries: Automotive, electronics, home & office appliances, medical, etc

5. Markets: 90% molds are exported to North America, South American, Europe and Australia.

Software we use

| 3D Modeling: Pro/ENGINEER , SolidWorks, Unigraphics 2D Drawing: Auto-CAD, E-drawing |

| Qualified suppliers | Mold base and mold steel from LKM, ASSAB, THYSSEN and DAIDO Hot runner system from YUDO, MOLD-MASTER, HASCO, DME, HUSKY. |

Molding Resin experience

| ABS, PC, PC+GF, PC/ABS, PBT, PA6+GF, PA66+GF, PPS, PU, PP, PE, TPE, TPU, LCP, Ultem, etc |

| Our capacity | Build 30 sets molds/month. |

| Minimum tolerance | 0.005mm |

Product Presentation:

How It Works

Plastic injection moulding is the process of creating component parts via the use of a mould. Hot liquid plastic is injected into a pre-set mould, allowed to cool and then released, collected and packaged.

With so many plastic injection moulded products surrounding us in our day-to-day lives, it is no surprise that making these products means that our machines can run 24 hours per day and 7 days per week.

The process of plastic Injection moulding

The liquid plastic is injected into the mould under pressure. It is

important that a tight pressure is kept to prevent air bubbles.

Either side of the mould is clamped together tightly. Once it has

been ensured that all cavities have been filled with plastic the

mould is allowed to cool.

Once cooled, the moving side of the mould is taken away from the

static side of the mould and the product is revealed.

After a run of the product has finished, the factory stores the

tooling and moulds securely until another batch of the product is

required.

The tool makers will be able to pick up where they left off and

create the same product or make modifications if required by the

customer.

Injection moulding is the most common method of fabricating high volumes of plastic parts. Many products are injection moulded, varying in size, complexity and end-use.

Order Processes

◆ RFQ Quotation ======= ◆ PO======= ◆ DFM ======= ◆ Mold Design

◆ Design Approved ======= ◆ Steel Ordering =======◆ Machining

◆ Mold Trial ========◆ Sample Approved =======◆ Texture =======◆

Delivery

Questions & Answers:

◆ How about the tolerance?

Mold tolerance 0.005 mm, Product tolerance 0.02 mm

◆ How about the largest mold you ever made?

1400mm*1100mm*1000mm and 10 tons

◆ What do you need for quotation?

We need product 2D drawing or 3D file or specific sample with

detailed explanation;

need to know the materials request for product or mold, also expected mold service life.

◆ How about the standard components you use?

We only use standard components from brand supplier like LKM,

DAIDO, HASCO, DME.

◆ Have you ever made over mold? What kind of materials you use?

We have good experience in over mold of

ABS+PC,PA+TPE,ABS+TPE,TPE+TPE.

◆ How do you make sure good quality?

We work with qualified suppliers, and source mold base and mold steel from LKM, ASSAB, THYSSEN and DAIDO; hot runner system from YUDO, MOLD-MASTER, HASCO, DME, HUSKY.

◆ How about the steel you usually use?

We only use raw materials with good quality and origin certificate.

We use steel of P20, P20H, 718H, NAK80, 1.2311, H13, 1.2344, 420SS,

S136, S-7 and 1.2767.

They are all from famous suppliers, such as LKM, ASSAB, THYSSEN and DAIDO.

◆ How long do you need for quotation?

Exact quotation will be available within 2-3 working days once we

get sufficient information.

◆ How many molds could you make every month?

35-40 SETS

◆ What’s the percentage of automobile molds you made, what’s the

brands?

About 40% of total molds are for automobile. TOYOTA, HONDA, JAGUAR,

BMW and BUICK.

If you have any questions, pls go ahead and contacts us, we are very pleased to show our price to you. Hope to hear from you soon. Thank you!